In commercial and industrial settings, especially in sectors like manufacturing, construction, and healthcare, the potential for electrical hazards and associated risks are magnified due to complex systems and high-powered equipment. These risks can lead to severe injuries, fatalities, and substantial operational disruptions. Electrical standard operating procedures (SOPs) provide clear guidelines for safe practices, to mitigate these dangers and ensure that workers are adequately trained, equipment is properly maintained, and hazards are systematically identified and controlled.

This article will dive into the key components and steps to implement electrical safety SOPs, in addition to their importance in not only protecting employees but also ensuring operational efficiency and compliance with regulatory requirements.

- Common Examples of Electrical Hazards in the Workplace

- Electrical Standard Operating Procedures: An Overview

- Why Electrical SOPs are Important

- Essential Components of Electrical Safety SOPs

- A Step-by-Step Guide to Developing & Implementing Electrical SOPs

- Leverage GoAudits to Digitize Your Electrical Safety SOPs & Inspections

- How Electrical SOPs Differ from General Safety Guidelines?

Common Examples of Electrical Hazards in the Workplace

Electrical hazards in the workplace are a significant concern, posing risks such as electric shocks, burns, and even fatalities. Understanding and mitigating these hazards is crucial for ensuring a safe working environment. Below are common examples of electrical hazards in the workplace you should be aware of:

- Faulty Wiring: Inadequate or deteriorated wiring can lead to overheating, fires, and electric shocks. Using wires of inappropriate size for the electrical load can cause overheating and potential fires.

- Damaged Tools or Equipment: Electrical tools and equipment are prone to wear and tear, leading to exposed wires, cracked insulation, or loose connections. Such defects can result in electric shocks or fires.

- Overloaded Circuits: Plugging too many devices into a single outlet or circuit can exceed its capacity, causing overheating and potential fires. It’s important to distribute electrical loads appropriately and use circuit breakers to prevent overloading.

- Exposed Electrical Parts: Exposed wires, open electrical panels, and unguarded live parts pose serious risks of electric shock. Ensuring all electrical components are properly enclosed and insulated is essential for safety.

- Exposure to Water: Water near electrical equipment increases the risk of electric shock. Avoid operating electrical devices in wet conditions, and ensure that equipment is kept dry and protected from moisture.

- Overhead Power Lines: Working near overhead power lines can be extremely dangerous due to the high voltages they carry. Maintaining a safe distance, typically at least 10 feet, and using non-conductive tools can help prevent accidental contact.

- Improper Grounding: Improper or missing grounding can lead to dangerous situations. Proper grounding ensures that excess electricity has a safe path to the ground, preventing electric shocks.

- Overloaded Sockets: Using multiple high-power devices in a single socket can cause overheating and fires. Power strips should be used with surge protection to avoid daisy-chaining multiple extension cords.

Electrical Standard Operating Procedures: An Overview

Electrical SOPs are documented guidelines that outline safe and standardized methods for performing electrical tasks, ensuring worker safety and operational efficiency. They outline mandatory protocols for the safe handling, maintenance, and operation of electrical systems to mitigate risks associated with electrical hazards in workplaces.

Electrical SOPs are essential for anyone who works with or near electrical equipment or systems. Essentially, any individual whose job involves interacting with electrical hazards, or who could potentially be exposed to them, should be following an electrical safety SOP.

Why Electrical SOPs are Important

Let’s look at some reasons why electrical safety standard operating procedures are important.

- Standardize procedures to ensure consistent, error-free operations across teams

- Provide clear training guidelines for new employees, improving onboarding and task execution

- Define responsibilities to establish accountability and reduce ambiguity in daily operations

- Reduce risks and equipment failures through proactive maintenance and safety protocols

- Streamline troubleshooting and minimize downtime with well-documented procedures

- Demonstrate regulatory compliance and readiness during audits and inspections

- Identify and mitigate electrical hazards through structured risk assessments

- Ensure compliance with standards like OSHA and NFPA to avoid penalties

Essential Components of Electrical Safety SOPs

Here are the key components of electrical safety SOPs.

Scope and Objective

Every electrical safety SOP must begin by clearly defining its scope and objective. You should specify the environments, equipment, personnel, and activities the SOP covers. The objective should focus on protecting workers from electrical hazards and ensuring regulatory compliance through systematic, safe practices.

Roles and Responsibilities

An electrical SOP must assign specific roles and responsibilities. You should identify and outline the duties of all individuals involved, including qualified electrical workers, supervisors, contractors, and safety officers. It ensures that everyone understands their obligations in maintaining a safe work environment.

Hazard Identification and Risk Assessment Protocols

Electrical safety SOP should incorporate structured protocols for hazard identification and risk assessment. You must emphasize conducting thorough job hazard assessments (JHAs) to detect potential electrical risks before beginning any work.

Safe Work Procedures and Safety Instructions

You must provide step-by-step safety instructions for routine and non-routine tasks. Each procedure should include necessary precautions, specific methods for minimizing exposure to electrical hazards, and clear operational sequences.

Equipment and Materials Required for Performing the Tasks

A detailed list of equipment and materials essential for electrical tasks must be included. You should specify the types, standards, and conditions of the tools permitted. Guidelines for inspection, use, and storage of equipment help ensure readiness and reliability.

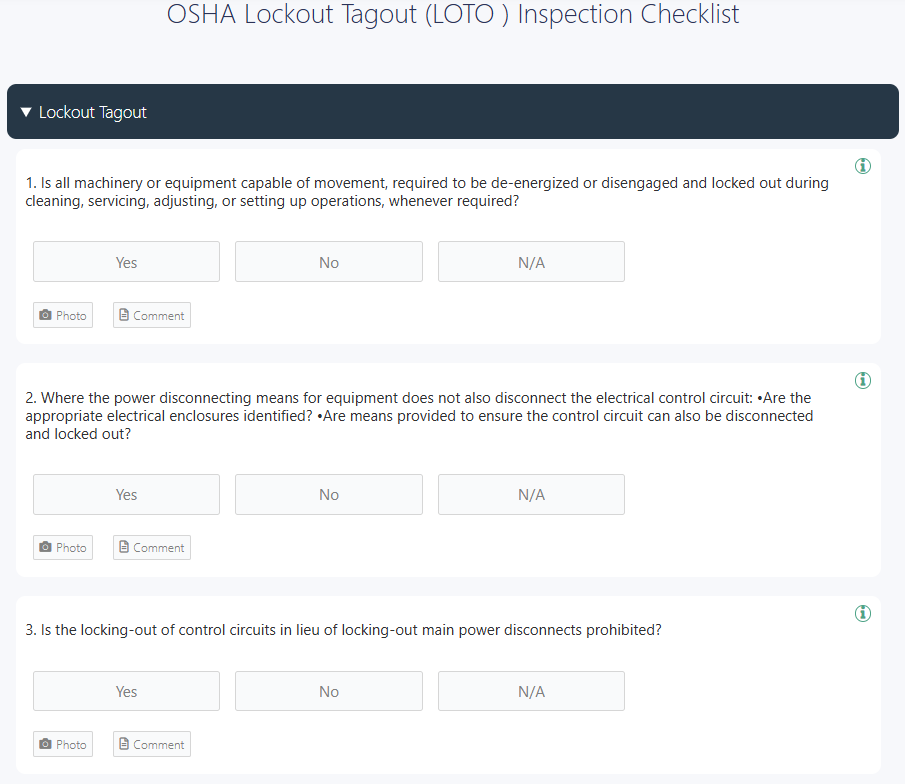

Lockout/Tagout (LOTO) Procedures

No electrical safety SOP is complete without comprehensive lockout/tagout (LOTO) procedures. You should describe protocols for isolating and securing hazardous energy before servicing or maintenance activities. Only authorized personnel should perform LOTO, and all devices should be labeled, locked, and verified according to strict standards.

👉 You can use the free GoAudits lockout/tagout procedure checklist or OSHA lockout tagout inspection checklist to perform LOTO procedures effectively.

Use of Personal Protective Equipment (PPE)

Your SOP must address the selection, use, and maintenance of personal protective equipment (PPE). You should detail the specific PPE required for various tasks, such as insulated gloves, arc flash suits, and face shields. Procedures for PPE inspection, proper fitting, and timely replacement of PPE must also be established.

👉 You can use free GoAudits PPE inspection checklists based on PPE SOPs to ensure the proper selection, maintenance, and use of PPEs.

- PPE Audit Checklist

- PPE Hazard Assessment Template

- Donning and Doffing PPE Checklist

- PPE Daily Inspection & PPE Monthly Inspection Checklist

- Security Guard PPE Checklist

- OSHA PPE Checklist

Inspection and Maintenance Schedules

Your electrical SOP should define the frequency, methods, and responsible personnel for inspections and support ongoing compliance with safety standards,

👉 GoAudits offers the following checklists to help you perform inspections and preventive maintenance checks of electrical systems, equipment, and machinery, reducing unexpected failures.

- Machine Preventive Maintenance Checklist

- Air Compressor Preventive Maintenance Checklist

- Conveyor Preventive Maintenance Checklist

- HVAC Preventive Maintenance Checklist

- Plumbing Preventive Maintenance Checklist

Emergency Response and Shut-Off Procedures

Effective electrical safety SOPs must outline emergency response and shut-off procedures. You should provide immediate action plans for electrical incidents, including electric shocks, arc flashes, or fires. Emergency shut-off locations, reporting mechanisms, and first-aid steps must be clearly specified.

Electrical Safety Training and Qualification Requirements

You must establish mandatory training and qualification standards within the SOP. Your document should describe initial training, refresher courses, hands-on practice requirements, and the criteria for considering a worker as ‘qualified’ under OSHA and NFPA guidelines.

Compliance Documentation and Recordkeeping

Every electrical safety SOP should include a section on documentation and recordkeeping. You must maintain thorough records of hazard assessments, training certifications, inspections, incidents, corrective actions, and electrical audits.

👉 Find out how to perform electrical audits effectively with a step-by-step guide.

A Step-by-Step Guide to Developing & Implementing Electrical SOPs

Here’s a comprehensive, step-by-step guide to help you through the process:

1. Identify Electrical Hazards

Begin by systematically identifying potential electrical hazards within your facility. This includes assessing equipment, wiring, and operational practices to pinpoint areas where electrical risks may arise.

2. Understand Regulatory Requirements and Standards

Familiarize yourself with the electrical safety standards applicable to your region and industry. For instance:

- The National Electrical Code (NEC) outlines safety requirements for electrical installations in the US.

- BS 7671, also known as the IET Wiring Regulations, provides comprehensive guidelines for the design, installation, and inspection of electrical systems in the UK.

- Globally, the IEC 60364 series provides guidelines for electrical installations.

Ensure that your SOPs align with these standards to maintain compliance and safety.

3. Assess Organizational Needs

Evaluate your organization’s specific requirements, including the types of electrical equipment used, the complexity of operations, and the skill levels of personnel. This assessment will inform the development of tailored SOPs that address unique operational contexts.

4. Involve Qualified Personnel

Engage experienced electricians, safety officers, and relevant stakeholders in the electrical SOP development process. Their expertise ensures that procedures are practical, comprehensive, and aligned with both safety standards and operational realities.

5. Write Clear and Concise Procedures

Develop electrical SOPs that are straightforward and easy to understand. Use clear language, define technical terms, and structure procedures logically. Incorporate visual aids like flowcharts or diagrams where applicable to enhance comprehension.

6. Review and Validate the SOP

Before implementation, have the electrical SOP formats reviewed by additional experts or safety committees to ensure accuracy and completeness. Conduct pilot tests to validate the procedures in real-world scenarios, making adjustments as necessary based on feedback and observed outcomes.

7. Use Digital Checklists and Templates

Use digital tools to manage and disseminate electrical SOP formats effectively. Digital tools and SOP software like GoAudits offer customizable checklists and templates that enhance the accessibility of SOPs, facilitate real-time reporting, and simplify audits.

- Electrical Safety Inspection Checklist

- Electrical Safety Checks

- Free Electrical Inspection Forms

- OSHA Electrical Safety Inspection Checklist

- Electrical Panel Maintenance Checklist

- Equipment Inspection Form

8. Train Employees

Conduct comprehensive training sessions to familiarize employees with the electrical SOPs. Training should cover the rationale behind procedures, step-by-step instructions, and the importance of compliance. Incorporate hands-on demonstrations and assessments to reinforce learning.

9. Schedule Regular Reviews and Updates

Establish a routine schedule for reviewing and updating electrical SOP formats to reflect changes in regulations, technology, or operational practices. Solicit feedback from employees to identify areas for improvement. Regular audits and inspections can also highlight the need for revisions.

Leverage GoAudits to Digitize Your Electrical Safety SOPs & Inspections

Managing electrical safety procedures manually wastes time, increases errors, and puts your workforce at risk. When you digitize your electrical SOPs with GoAudits, you streamline compliance, boost efficiency, and improve safety outcomes across your organization. You don’t have to rely on paper-based inspections that lead to missed hazards and inconsistent reporting. With GoAudits safety inspection software, you:

- Conduct electrical safety audits directly from any device, whether you’re online or offline.

- Access a wide range of pre-built health and safety audit checklists or customize them to meet your business and industry requirements. Capture photos and add time stamps, geolocation, and e-signatures to provide visual evidence and ensure transparency.

- Generate branded, professional electrical inspection reports the moment an inspection is completed. These audit reports contain corrective actions, photos, timestamps, and geolocation data. Customize these reports and share them with relevant stakeholders.

- Assign corrective actions during inspections. Set deadlines, send reminders, and trigger escalations for overdue actions. Track every task from creation to closure with full visibility.

- Monitor audit performance and scores across locations with real-time dashboards. Identify recurring issues and high-risk areas, and track trends that matter most for your electrical safety programs.

How Electrical SOPs Differ from General Safety Guidelines?

Electrical safety SOPs and general safety guidelines both aim to promote workplace safety, yet they differ significantly in their scope, specificity, risk mitigation focus, implementation requirements, and documentation and training.

Scope and Specificity

Electrical SOPs are highly detailed documents tailored to specific tasks involving electrical systems. They provide step-by-step instructions for activities such as equipment maintenance, lockout/tagout procedures, and emergency responses. These SOPs are often developed in accordance with standards like NFPA 70E and OSHA regulations.

General safety guidelines offer broad principles applicable across various workplace scenarios. They cover topics like fire safety, ergonomics, and general hazard awareness but lack the detailed procedures found in electrical SOPs.

Risk Mitigation Focus

Electrical SOPs concentrate on mitigating specific risks associated with electrical work, such as electric shock, arc flash, and equipment malfunction. They outline protective measures, including the use of PPE, grounding techniques, and safe work practices.

General safety guidelines aim to reduce common workplace hazards, promoting overall safety culture and compliance. While they address a wide range of risks, they do not dive into the specialized precautions necessary for electrical safety.

Implementation Requirements

Electrical SOPs require adherence to specific regulatory standards and often involve detailed planning, specialized training, and regular audits. Organizations must ensure that electrical systems are designed, installed, and maintained according to established codes and that employees are trained in safe work practices.

General safety guidelines are typically implemented through company-wide policies and training programs. They act as a foundation for creating a safe work environment but may not require the same level of technical detail or regulatory compliance as electrical SOPs.

Documentation and Training

Electrical SOPs necessitate comprehensive documentation, including detailed procedures, safety protocols, and maintenance records. Training programs must be specific to electrical tasks, ensuring that employees understand the hazards and the correct procedures to mitigate them.

General safety guidelines involve broader training initiatives aimed at raising awareness and promoting safe behaviors across the organization. Documentation may include safety manuals and general procedures but lacks the task-specific detail found in electrical SOPs.