Keeping workers safe on the job isn’t only about handing out protective gear. It also involves making sure everyone knows how to use it properly. PPE standard operating procedures (SOPs) provide clear instructions on when and how to wear personal protective equipment, as well as whether the PPE is in good condition. PPE SOPs prevent accidents and ensure compliance with safety regulations. Without well-defined SOPs, workers may misuse, forget, or ignore PPE, putting them at higher risk of accidents. A solid set of procedures helps create consistency, reduces confusion, and reinforces a strong safety culture in the workplace.

This article will break down why PPE SOPs matter, what they should include, and how to implement them effectively. Whether you’re updating existing procedures or starting from scratch, having a clear plan in place can make all the difference in keeping your employees safe.

Understanding PPE Standard Operating Procedures

Personal Protective Equipment (PPE) SOPs are essential protocols designed to safeguard employees from workplace hazards by ensuring the proper selection, use, maintenance, and disposal of protective gear. These procedures not only enhance worker safety but also ensure compliance with health and safety regulations.

Key Components of PPE SOPs

A well-structured PPE SOP encompasses several critical components:

- Identifying Workplace Hazards: Evaluating the work environment to pinpoint potential physical, chemical, biological, and ergonomic hazards that necessitate PPE.

- Determining Suitable PPE: Selecting appropriate protective equipment tailored to specific hazards, such as helmets for head protection, safety glasses for eye safety, gloves for hand protection, and respirators for respiratory safety.

- Donning and Doffing Procedures: Providing step-by-step instructions on how to correctly put on (don) and remove (doff) PPE to prevent contamination and ensure maximum protection.

- Usage Scenarios: Clearly defining situations and tasks where PPE is mandatory to ensure employees understand when and why specific PPE is required.

- Hygiene Practices: Emphasizing the importance of personal hygiene in conjunction with PPE use, including guidelines for cleaning and sanitizing equipment.

- Routine Inspections: Outlining procedures for regular inspections of PPE to detect signs of wear, damage, or contamination.

- Cleaning and Maintenance: Providing instructions for proper cleaning methods and maintenance routines to prolong the lifespan and effectiveness of PPE.

- Storage Protocols: Recommending appropriate storage conditions to protect PPE from damage, contamination, or degradation, such as storing equipment in clean, dry, and designated areas.

- Employee Training Programs: Implementing educational sessions that cover the correct selection, use, and care of PPE.

- Monitoring and Enforcement: Establishing systems to monitor PPE usage and enforce compliance, including regular audits, supervision, and feedback mechanisms to address non-compliance issues.

How To Create & Implement PPE SOPs

Below is a step-by-step guide to help you create and implement effective PPE SOPs:

1. Conduct Hazard Assessments

Begin by identifying and evaluating potential hazards in the workplace. This involves examining work practices, processes, job procedures, equipment, and the work environment to detect any risks that necessitate PPE usage. A thorough hazard assessment forms the foundation of your PPE program.

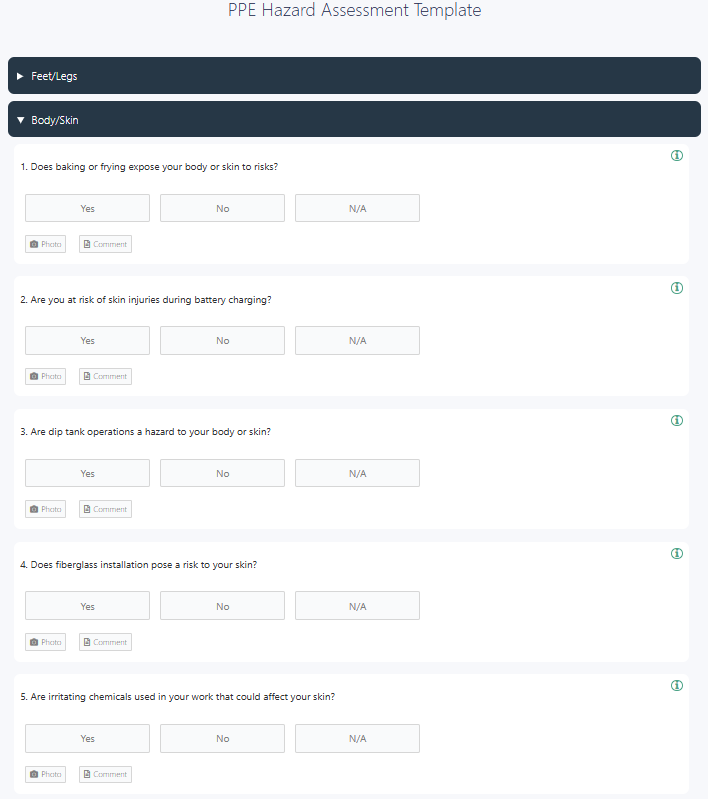

Here’s a PPE hazard assessment checklist template you can use to get started:

2. Determine Required PPE

Based on the hazard assessment, ascertain the specific types of PPE needed to mitigate identified risks, ensuring effective protection. Consider factors such as the nature of the hazard, the degree of exposure, and the suitability of PPE for the tasks performed.

3. Develop the SOP Document

Draft a clear and concise SOP document that details the procedures for PPE usage. This document should include:

- Purpose and Scope: Define the objectives and applicability of the SOP.

- Responsibilities: Outline the duties of employers, supervisors, and employees regarding PPE.

- PPE Selection and Use: Specify criteria for PPE selection, proper usage instructions, and limitations.

- Maintenance and Storage: Provide guidelines for the care, cleaning, and storage of PPE.

- Training Requirements: Detail the training programs to ensure competent PPE use.

- Emergency Procedures: Describe actions to take in case of PPE failure or related emergencies.

Ensure the SOP is easily understandable and accessible to all employees.

4. Involve Relevant Stakeholders

Engage employees, safety officers, and management in the development and review of the PPE SOP. Collaborative involvement ensures that the procedures are practical, comprehensive, and have the support of all parties. Incorporating feedback from those directly affected fosters a culture of safety and compliance.

5. Train Employees

Implement training programs to educate employees on the correct selection, use, and maintenance of PPE. Training should cover:

- When and why PPE is necessary

- How to properly don, adjust, wear, and remove PPE

- Understanding the limitations of PPE

- Proper care, maintenance, and disposal of PPE

Regular training sessions reinforce the importance of PPE and ensure ongoing competency.

6. Establish PPE Protocols

Develop and implement protocols that integrate PPE usage into daily operations, including the following:

- Enforcing the consistent use of PPE in designated areas

- Regular PPE inspections to ensure it’s in good condition

- Procedures for replacing damaged or defective PPE

Clear protocols promote a safe working environment and ensure compliance with safety standards.

7. Monitor Compliance

Regularly observe and assess compliance with PPE protocols. Supervisors should:

- Conduct routine checks to ensure proper PPE usage.

- Address non-compliance promptly through retraining or disciplinary actions.

- Encourage employees to report issues or suggest improvements related to PPE.

- Active monitoring helps identify gaps and reinforces the importance of PPE in workplace safety.

8. Review and Update SOPs

Periodically review and revise the PPE SOP to reflect changes in workplace conditions, equipment, or regulations. Regular updates ensure that the SOP remains relevant and effective in addressing current hazards. Engage stakeholders in the review process to incorporate diverse perspectives and expertise.

Leverage PPE SOP Templates

PPE SOP templates offer numerous benefits, including the following:

- Accelerated SOP Development

Using PPE SOP templates streamlines the creation process, enabling you to develop and implement comprehensive procedures swiftly. They offer predefined structures and content, reducing the time required to draft SOPs from scratch and ensuring timely compliance with regulations.

- Customization for Specific Needs

While SOP templates provide a foundational structure, they are flexible and can be tailored to meet specific departmental requirements. It ensures that each SOP addresses unique hazards and operational nuances, enhancing the relevance and effectiveness of safety protocols.

👉 You can use SOP software like GoAudits to access and customize PPE SOP templates.

GoAudits offers a wide range of PPE inspection checklists. You can sign up for free and start using these checklists. You can even create your own checklists or let us do it for you at no additional cost.

👉 Free & Customizable PPE SOP Templates

→ PPE Hazard Assessment Template

→ PPE Audit Checklist

→ Daily PPE Inspection Checklist

→ Donning and Doffing PPE Checklist

→ Arc Flash PPE Suit Inspection Checklist

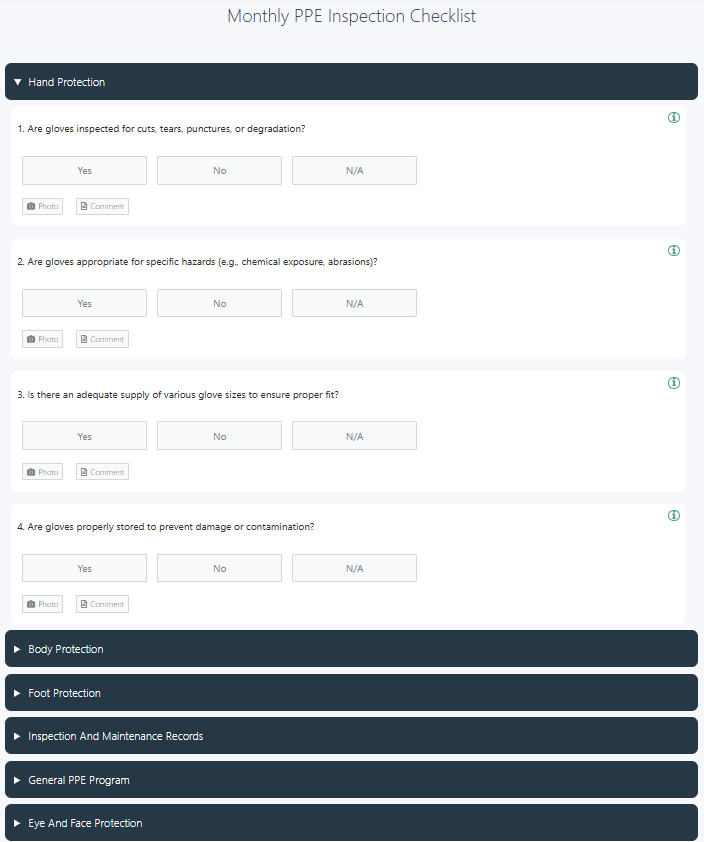

→ Monthly PPE Inspection Checklist

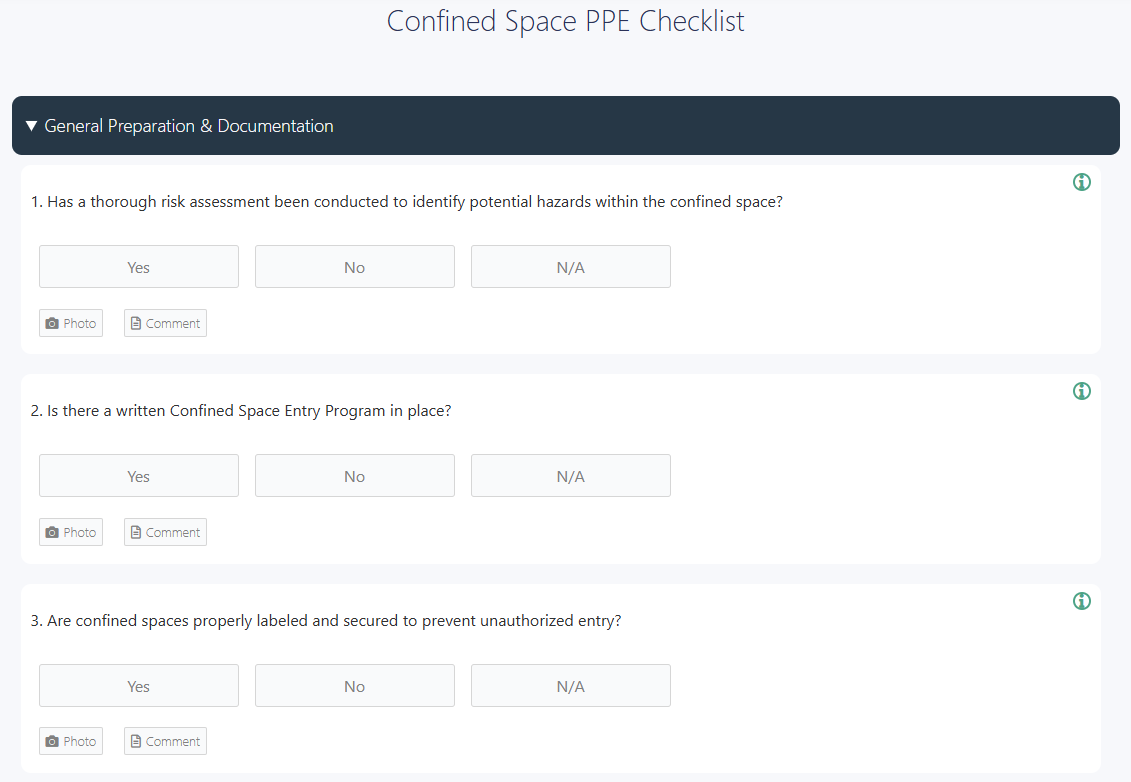

→ Confined Space PPE Checklist

→ Security Guard PPE Checklist

→ Firefighter PPE Inspection Checklist

→ OSHA Personal Protective Equipment (PPE) Checklist

- Improved Documentation and Accessibility

Using templates enhances the organization and clarity of SOP documentation. A well-structured template ensures that all critical information is systematically presented, making it easier for employees to understand and follow. Additionally, standardized documents are more accessible, help in training, and ensure that all personnel can readily reference the procedures.

- Consistency Across Departments

SOP templates promote uniformity in SOPs across various departments. A standardized format ensures that all employees follow the same procedures, minimizing variability and potential errors. It is crucial to maintain high safety standards and ensure that all team members are aligned in their practices.

- Easy Updates and Modifications

Regular updates to SOPs are necessary to reflect changes in regulations, equipment, or processes. PPE SOP templates facilitate straightforward modifications, allowing you to efficiently incorporate updates without overhauling the entire document. It ensures that your safety procedures remain current and effective.

Convert PPE SOPs into Actionable Checklists with GoAudits

PPE protocols are an essential part of workplace health and safety procedures. Ensuring compliance with these protocols and other health and safety standards requires a structured, efficient approach.

GoAudits safety inspection software is an all-in-one solution to streamline this process by transforming detailed SOPs into practical, actionable digital checklists. It helps simplify workplace safety inspections, improve safety procedures & practices, and enhance both operational efficiency and compliance monitoring.

Here’s how:

- Choose from a library of PPE templates and other health & safety audit checklists or convert extensive PPE SOPs into user-friendly digital checklists. With a simple drag-and-drop interface, you can create custom checklists tailored to your specific requirements, ensuring all critical aspects of your PPE protocols are covered.

- Conduct PPE inspections up to 5 times faster even when you’re offline with the GoAudits app, available on the web, iOS, and Android.

- Attach photos, annotations, e-signatures, and geolocation directly from the app to provide evidence and ensure accountability and transparency.

- Generate detailed, professional reports after each inspection. These reports include all important information, such as attached photos, assigned actions, timestamps, and geolocation. You can customize these reports, review them, and share them with relevant stakeholders.

- Assign corrective actions and other tasks to specific team members, set priorities, and establish due dates. Automated notifications and reminders ensure that corrective actions are tracked and completed promptly and efficiently.

- Get a comprehensive overview of audit performance and scores across various locations, teams, or topics. Monitor compliance trends and identify areas for improvement with smart dashboards designed to enable data-driven decision-making.

What are Some Common PPE SOP Examples?

Here’s how PPE SOPs are used across different industries for different tasks.

General PPE Usage SOPs

They outline universal requirements applicable across industries, ensuring workers understand PPE selection, fit, usage, and disposal. Key components include:

- Identifying workplace hazards that necessitate PPE

- Ensuring proper fitting and comfort for all users

- Regular inspection and maintenance of PPE

- Proper storage and disposal guidelines

Industry-Specific PPE SOPs

Different industries require specialized PPE due to unique risks.

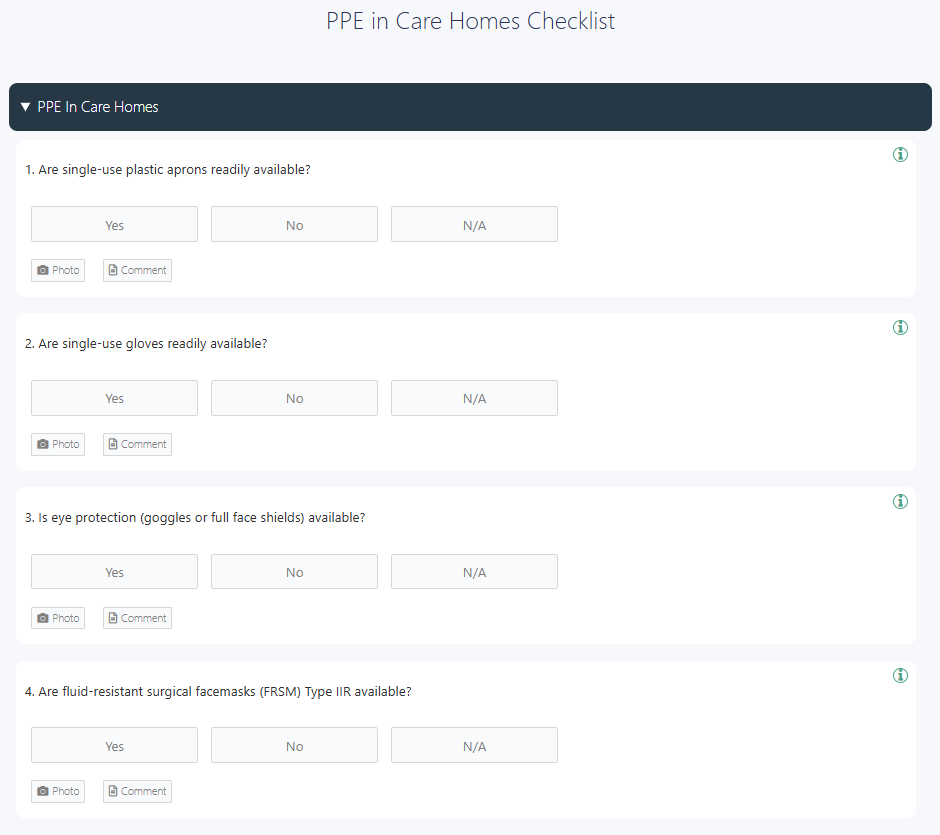

In healthcare, PPE SOPs emphasize the use of gloves, masks, gowns, and eye protection to prevent the transmission of infectious agents. SOPs detail protocols for donning and doffing PPE to avoid self-contamination.

Here’s an example of a PPE checklist for care homes:

PPE SOPs in the manufacturing industry focus on protective clothing, safety shoes, hearing protection, and eye guards to shield workers from mechanical hazards, noise, and chemical exposures.

In the construction industry, PPE SOPs highlight the necessity of hard hats, high-visibility vests, fall protection harnesses, and steel-toed boots to protect against falls, falling objects, and other site-specific dangers.

SOPs for Specific PPE Categories

Each type of PPE has its own set of SOPs to ensure proper protection.

- Eye and Face Protection: Outline the use of safety glasses, goggles, or face shields when handling hazardous materials or operating machinery that may emit debris.

- Hand Hygiene: Provide guidelines for selecting appropriate gloves based on the task for adequate protection against chemicals, cuts, or heat.

- Hearing Protection: Recommend the use of earplugs or earmuffs in environments with noise levels exceeding safe thresholds to prevent hearing loss.

- Skin and Body Protection: Advise on wearing protective clothing, such as lab coats or coveralls, to shield the skin from chemical splashes or biological agents.

- Foot and Leg Protection: Suggest safety boots with features like steel toes and slip-resistant soles to guard against foot injuries in hazardous work areas.

- Respiratory Protection: Detail the selection and use of appropriate respirators or masks to protect against inhalation of harmful substances.

Here’s an example of a monthly PPE inspection checklist:

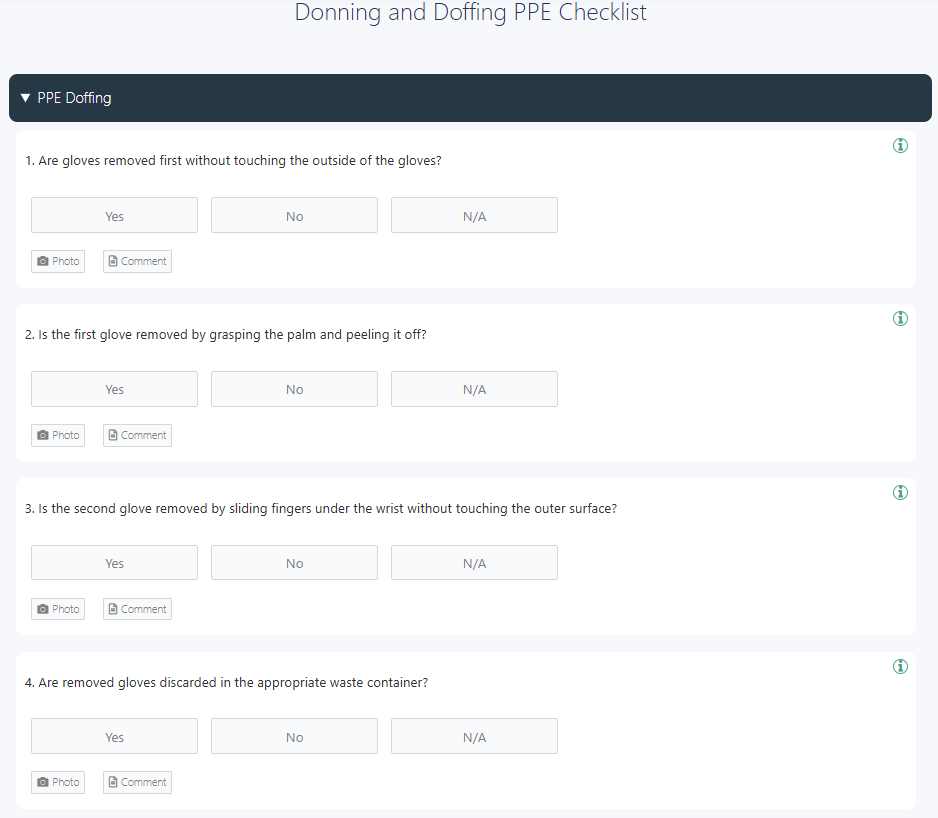

PPE Removal SOPs

Proper doffing procedures minimize contamination risks. Key steps include:

- Removing gloves first, avoiding skin contact with contaminated surfaces.

- Taking off gowns, coveralls, or aprons carefully to prevent exposure.

- Removing face shields or goggles without touching the front.

- Taking off masks or respirators last, handling straps only.

- Performing thorough hand hygiene immediately after removal.

Here’s an example of PPE donning and doffing checklist:

Establish a specific order for doffing PPE to minimize the risk of self-contamination, such as removing gloves first, followed by goggles, gown, and mask. Provide instructions for the safe disposal of single-use PPE and the decontamination of reusable equipment.

Task-Based PPE SOPs

Certain tasks require specialized PPE procedures:

- Chemical Handling: SOPs cover selecting chemical-resistant gloves, face shields, aprons, and respirators based on material safety data sheets (MSDS).

- Fall Protection: Guidelines include using harnesses, lanyards, and anchor points in construction and maintenance work.

- Welding and Cutting: Mandates flame-resistant clothing, welding helmets, and high-heat gloves. GoAudits offers a wide range of checklists to help you ensure the safe operations of welding machines.

- Confined Space Entry: Requires full-body protection, respiratory gear, communication devices, and risks associated with confined spaces.

Here’s an example of a PPE checklist for confined spaces:

Why are PPE SOPs Important?

PPE SOPs are essential to maintaining a safe and efficient workplace. Here are some reasons why:

- Ensures Compliance with Safety Regulations

Adhering to PPE SOPs guarantees that your organization meets established safety standards and legal requirements. It is essential to avoid potential legal ramifications and demonstrate a commitment to employee well-being.

- Reduces Workplace Injuries and Illnesses

Consistent use of PPE, as outlined in SOPs, minimizes exposure to hazards, reducing the incidence of workplace injuries and illnesses. It fosters a safer working environment.

- Lowers Healthcare and Compensation Costs

By decreasing the number of workplace incidents, PPE SOPs contribute to lower healthcare expenses and workers’ compensation claims. It positively impacts the organization’s financial health.

- Standardizes PPE Usage Across Teams

SOPs provide clear guidelines on the selection, use, and maintenance of PPE, ensuring uniformity across all departments. It eliminates confusion and promotes cohesive safety practices.

- Enhances Employee Awareness and Training

Regular training on PPE SOPs educates employees about potential hazards and the correct use of protective equipment. Informed employees are more likely to adhere to safety protocols, reducing the risk of accidents.

- Improves Efficiency and Productivity

A safe workplace, supported by well-implemented PPE SOPs, leads to fewer disruptions caused by accidents. It allows for smoother operations and improved productivity.

- Improves PPE Maintenance and Longevity

SOPs include protocols for the proper care and maintenance of PPE. Adhering to these guidelines extends the lifespan of equipment, ensuring reliability and reducing replacement costs.

- Supports Emergency Preparedness

Incorporating PPE SOPs into emergency response plans ensures that employees are equipped and trained to handle unexpected hazardous situations effectively, minimizing harm during emergencies.

- Fosters a Stronger Safety Culture

Implementing and enforcing PPE SOPs cultivates a culture of safety within the organization. It encourages proactive hazard identification and risk management, leading to continuous improvements in workplace safety.