In the UK, organisations must comply with health, safety, and environmental duties set out under the Health and Safety at Work etc. Act 1974 and related regulations. This means identifying risks, implementing effective controls, involving employees, and managing safety as an ongoing process using a PDCA (Plan-Do-Check-Act) approach. It is also important to distinguish between HSE as health, safety, and environment and the Health and Safety Executive (HSE), the UK’s statutory regulator. While the regulator enforces the law and provides guidance, responsibility for managing risk always sits with the organisation itself. HSE audits play a key role by evaluating how effectively safety arrangements are planned, implemented, and maintained, supporting continuous improvement and demonstrating due diligence.

This article will explore HSE audit types, steps to perform internal audits, why they are essential, and free audit checklists.

What is an HSE Audit?

An HSE audit is a structured evaluation of an organisation’s health, safety, and environmental management systems. It examines whether policies, procedures, and controls are not only documented but effectively implemented and aligned with legal requirements, recognised standards, and organisational objectives.

Rather than a quick compliance check, an HSE audit assesses the effectiveness of risk controls, systems, and behaviours. It identifies gaps, highlights good practice, and provides evidence-based insights that help organisations improve performance, reduce risk, and demonstrate accountability to regulators and stakeholders.

Types of HSE Audits

Let’s explore the main types of HSE inspections in detail.

HSE Internal Audits and External Audits (and Who Performs Them)

Internal HSE audits are conducted by trained personnel or designated audit teams within the organisation. They verify adherence to internal policies and regulatory requirements, assess system performance, and prepare the organisation for external scrutiny. Internal audits can be scheduled regularly (monthly, quarterly, or annually) and are essential for ongoing monitoring and continuous improvement.

External HSE audits are carried out by independent third parties, such as certification bodies, consultants, or regulatory inspectors. Auditors provide an objective assessment of compliance with laws, standards, and contractual obligations. External audits are often linked to certification programmes (for example, ISO 45001) or regulatory inspections and carry greater weight with clients and authorities due to their impartiality.

Compliance Audits

A compliance audit focuses specifically on whether an organisation meets applicable legal and regulatory requirements. These audits examine documentation, permits, records, and practices to determine conformity with statutes and standards designed to protect health, safety, and the environment. The primary aim is to confirm legal compliance and identify any non-conformities that could lead to enforcement action or penalties if unaddressed.

System Audits

System audits evaluate the effectiveness of the overall HSE management system, and not just specific activities. They examine how policies, procedures, risk assessments, and training are integrated into business processes and whether they drive consistent performance. It helps verify that the management framework is robust, systematic, and capable of keeping pace with organisational change and regulatory updates.

Process/Behavioural Audits

Process audits focus on defined workflows or activities to determine whether specific procedures are followed and risks are controlled.

For example, machine maintenance, confined space entry, or chemical handling.

Behavioural audits look at how people behave in their work environment, identifying unsafe actions or habits that may not be evident from documentation alone. These audits emphasise observing worker behaviours and interactions with safety systems to support behavioural safety improvements.

HSE Unannounced Inspections and Planned Audits

Unannounced inspections are spontaneous checks that assess real-time compliance and operational practices without prior notice. They help capture an accurate picture of daily practices, reducing the risk of audit preparation masking underlying issues.

Planned audits are scheduled in advance and typically include detailed scopes and objectives agreed beforehand. These provide an opportunity for thorough preparation, documentation review, and engagement with relevant personnel.

HSE Inspections that are Part of HSE Audit Programs

An HSE audit program depends on structured, targeted inspections. Below are key types of HSE inspections commonly implemented in UK workplaces to support audit programs, each addressing specific risk areas and regulatory requirements:

1. HSE Workplace Inspections and HSE Site Inspections

Workplace inspections and site inspections form the foundation of any effective safety management system. These assess whether the work environment, operations, tools, and behaviours comply with legal obligations and internal policies. They typically check for hazards such as unsafe equipment, poor housekeeping, blocked escape routes, inadequate signage, and incorrect use of personal protective equipment (PPE). Inspections should be scheduled regularly and after significant changes on site to ensure ongoing risk control. Records should be maintained for audit traceability.

2. HSE Scaffold Inspection

Scaffolding inspections are critical where work at height is involved. Under UK health and safety law, scaffolds must be inspected:

- Before first use after erection,

- At least every seven days,

- After any event that could affect stability (for example, severe weather or alterations).

A competent person, typically someone trained under recognised schemes such as CISRS, must carry out these inspections to verify structural integrity, correct assembly, proper platforms, secure guardrails, and safe access.

👉 Free Resources

3. HSE LOLER Inspection

LOLER (Lifting Operations and Lifting Equipment Regulations 1998) inspections focus on equipment used to lift or lower loads. All lifting equipment and accessories must undergo periodic thorough examinations by a competent person, with the frequency determined by risk and usage.

For example, equipment used to lift people usually requires examination every six months, while other lifting appliances often require it at least every 12 months in the absence of a formal examination scheme. LOLER inspections confirm that lifting equipment remains fit for purpose, safe, and clearly marked with safe working.

4. HSE LEV Inspection

Local exhaust ventilation (LEV) inspections are required where LEV systems are used to control airborne contaminants such as dust, fumes and vapours under the Control of Substances Hazardous to Health (COSHH) regulations.

LEV inspections and tests ensure that ventilation systems continue to operate effectively, protecting workers’ respiratory health. A proper inspection involves both a visual check of components and performance testing (airflow, extraction effectiveness), typically on a maximum 14-month cycle or more frequently based on process risk.

5. HSE Ladder Inspection

Ladder inspections focus on access equipment that presents significant fall risks. Employers are required to ensure ladders and stepladders are suitable for their intended use and regularly inspected by a competent person in accordance with manufacturer guidance.

Good practice includes pre-use checks for visible defects (such as bent stiles or cracked rungs) and scheduled detailed inspections with records of findings. These checks help identify deterioration early, keeping access equipment safe and reliable.

HSE Audit Process: Steps-By-Step Guide

An effective HSE audit applies the PDCA approach to ensure audits drive measurable improvements, strengthen legal compliance and your safety management system, and transform HSE audits from a compliance obligation into a proactive management tool. It ensures audits are planned, executed, and followed up on consistently. Follow the steps below to perform an internal HSE audit aligned with the PDCA approach.

1. PLAN: Audit Planning and Preparation

This stage defines what will be audited, why, and how.

Key activities include:

- Define the audit scope (site, process, activity, or system level)

- Set clear audit objectives aligned with legal duties, ISO standards, or internal policies

- Identify applicable regulations and standards

- Assemble a competent audit team with technical and operational knowledge

- Develop audit criteria and checklists

- Gather relevant documentation such as risk assessments, procedures, permits, training records, and previous audit reports

Clear planning prevents scope creep, improves audit efficiency, and ensures findings are defensible and actionable.

2. DO: Perform the HSE Internal Audit

This stage focuses on evidence-based assessment of how HSE controls are implemented in practice. Core audit activities include site and workplace inspections, interviews to verify understanding and implementation, document and record reviews to confirm legal and procedural compliance, and operational sampling to test consistency across shifts or locations.

Using HSE audit software or mobile apps with digital checklists improves accuracy, consistency, and traceability. Digital tools allow auditors to capture photos, assign findings instantly, and reduce manual reporting errors while maintaining a clear audit trail.

👉 Free Checklists

Sign up for free and start using these health & safety audit checklists, or digitise your health & safety SOPs into user-friendly checklists.

→ ISO 45001 Audit Checklist

→ Workplace Inspection Checklists

→ OHS Inspection Checklists & Templates

→ PPE Inspection Checklists & Forms

→ Hygiene Audit Checklists

→ Equipment Maintenance Logs

→ Fire Safety Inspection Checklist

→ Office Hazards Checklist

→ Safety Audit Template

→ OSHA Checklists & Audit Templates

3. CHECK: Document and Analyse Findings

Once evidence is collected, findings must be formally evaluated and documented.

This step involves:

- Recording non-conformances, observations, and good practices

- Assessing compliance gaps against legal and internal requirements

- Categorising findings by risk level and severity

- Identifying recurring or systemic issues

Clear, well-structured audit reports form the foundation for effective corrective action by linking findings to specific regulations or standards, explaining the risk clearly, and avoiding vague or subjective language.

4. ACT: Implement Corrective Actions

Audit value is realised only when issues are resolved, and not just recorded.

Key actions include:

- Conduct root cause analysis to address underlying failures, not symptoms

- Prioritise corrective actions based on risk and legal exposure

- Assign ownership and realistic deadlines

- Track actions to closure using a central system

Effective action management ensures high-risk issues are addressed first and prevents repeat findings in future audits.

5. REVIEW: Monitor Effectiveness and Improve

The final step closes the PDCA loop. It involves verifying that corrective actions are effective, reviewing performance trends across audits and inspections, updating risk assessments, procedures, and training where required, and refining the audit program based on lessons learned. Regular management review ensures audit outcomes influence resource allocation and long-term HSE performance.

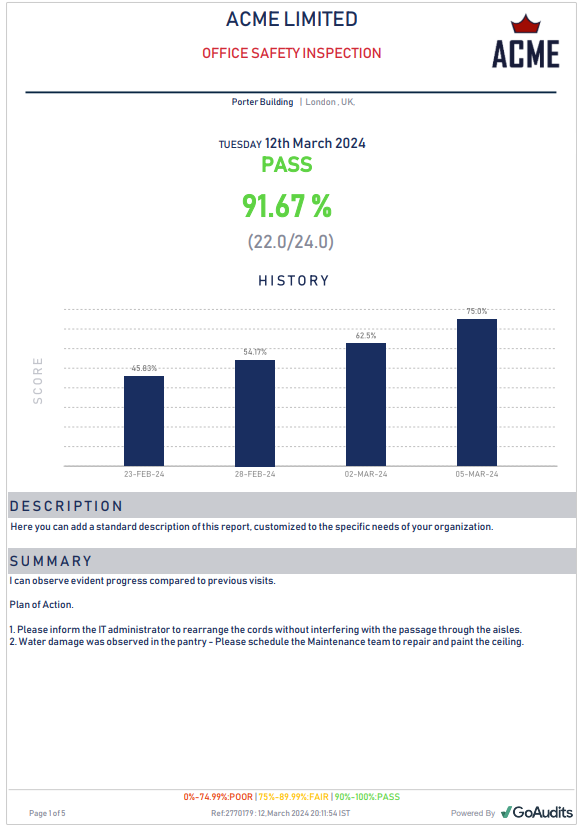

Free HSE Audit Report Sample

We used GoAudits to generate this HSE inspection report sample.

Digitise Your HSE Internal Audits with GoAudits

If you’re running HSE audits in spreadsheets, paper forms, or disconnected apps, the hardest part isn’t the audit. It’s everything after: writing the report, chasing evidence, assigning owners, and making sure corrective actions actually close out.

GoAudits enables organisations to replace manual processes with a mobile-first auditing tool, reducing administrative burden, improving compliance, and driving corrective action. From data capture to reporting and follow-up, the GoAudits HSE app centralises every step of the HSE audit lifecycle, so teams spend less time on paperwork and more time improving safety and standards.

- Use ready-made templates or create fully customised HSE audit checklists. Upload existing checklists in any format and have them digitised at no extra cost.

- Conduct HSE inspections on any device, even offline. Attach and annotate photos directly in the app. Record e-signatures, timestamps, and geolocation for traceability and accountability.

- Generate professional HSE audit reports immediately after each inspection. Reports are pre-filled with findings, photos, actions, and metadata—ready to share.

- Assign actions during the audit, set priorities and due dates, and track completion centrally. Ensure nothing is missed and responsibilities are clear.

- Route reports for approval, notify task owners, and trigger reminders automatically. Engage the right stakeholders at the right time.

- Monitor HSE audit results and performance across sites, teams, or topics using smart dashboards. Analyse historical results to identify recurring issues, trends, and risk areas.

- Plan audits in advance, track progress, and monitor overdue actions to maintain control and continuous improvement.

👉 Best for multi-site operations and high-risk environments: Whether you’re auditing retail, construction sites, manufacturing lines, warehouses, or facilities teams, GoAudits helps you keep audits consistent, evidence-based, and easier to manage.

Why are HSE Audits Performed

Here are some reasons why HSE audits are important:

- HSE audits uncover hidden hazards and weaknesses in controls, enabling corrective measures before incidents occur and reducing workplace injuries.

- Identifying and addressing risks early helps lower expenses related to accidents, insurance claims, legal penalties and operational downtime.

- A safer environment reduces interruptions from accidents and boosts workforce confidence, which in turn enhances workflow efficiency and output.

- HSE audits show regulators and insurers that you are actively meeting health, safety, and environmental obligations and mitigating risk.

- Regular audits signal commitment to safety and compliance, building trust with employees, clients, and external stakeholders.

- HSE audit highlights the most critical risks, enabling leaders to allocate budget and manpower where it delivers the greatest safety impact.

- Involving staff in audit processes and acting on findings reinforces shared ownership of safety and encourages active participation in hazard reporting.

FAQs

An HSE audit assesses the effectiveness of your safety management system, policies and procedures against standards and legal criteria, while an inspection focuses on identifying unsafe conditions or behaviours in the workplace at a specific moment in time. Audits are broader and periodic, while inspections are routine and operational.

There is no one-size-fits-all frequency, but most organisations schedule comprehensive HSE audits at least annually or biannually, with higher-risk operations requiring more frequent review to keep pace with changes and emerging hazards.

Typical noncompliances include missing personal protective equipment, inadequate signage, poor housekeeping, lack of emergency preparedness, incomplete maintenance checks and outdated documentation or training records.

Prepare by ensuring safety documentation is current, briefing staff on processes and what to expect, confirming that records and risk assessments are easily accessible, and making key personnel available for discussions with auditors.

An HSE audit program is a planned, structured set of audit activities scheduled over time to assess compliance, identify risks, track corrective actions and support continuous improvement across the organisation’s health, safety and environmental systems.

Develop a schedule based on your risk profile, regulatory requirements and past audit results; assign frequency, scope, auditors and deadlines, and ensure the calendar is communicated and maintained as part of your overall HSE management system.

Some best practices include conducting root cause analysis, prioritising actions by risk severity, assigning clear ownership and realistic deadlines, tracking progress digitally, and verifying effectiveness through follow-up reviews.