Key Takeaways

- Manufacturing inspections ensure products meet quality standards throughout production. They prevent defective products from reaching customers, reduce recalls, and enhance customer satisfaction.

- Traditional inspection methods face several challenges, including difficulty anticipating defects, slow issue resolution, and poor collaboration between departments.

- Digital manufacturing inspection apps address these challenges through real-time quality control, streamlined collaboration, quick issue resolution, and flexible inspection planning.

Manufacturing inspection is a critical process that spans every stage of production, from assessing raw materials to finished goods. Its effective implementation can significantly enhance product quality, reduce maintenance costs, and ensure compliance.

Read on to discover the benefits, types, and challenges of inspections in manufacturing. Additionally, learn why manufacturers are increasingly adopting digital manufacturing inspection tools.

- What are Manufacturing Inspections?

- Types of Manufacturing or Factory Inspections

- Free Factory Production Inspection Report Template

- Manufacturing and Factory Quality Inspection Checklists

- Why Digitize the Manufacturing Inspection Process?

- Streamline Manufacturing and Production Inspections With GoAudits

What are Manufacturing Inspections?

Manufacturing inspections, also known as production inspections, are a systematic process of evaluating and verifying that products meet quality standards throughout production. It employs visual inspection, measurements, and testing to identify and correct defects.

By identifying and rectifying issues early on, inspections prevent defective products from reaching customers, directly contributing to Quality Control. Furthermore, inspection data helps manufacturers analyze trends and improve their processes, achieving consistent quality over time.

Inspections are integrated throughout production to ensure quality isn’t just checked at the end, but built into the product from the beginning of the manufacturing process.

Difference Between Inspection and Testing in Manufacturing

Inspection and testing are both crucial for quality control in manufacturing, but they differ in their scope and methods.

Production inspection is a qualitative process of visually examining a product for defects, irregularities, or non-conformities against a set of standards. This is often done by a person using basic tools like calipers to check dimensions or a magnifying glass to find cosmetic flaws like scratches. Inspections can happen at various stages, such as when raw materials arrive, during production, or before shipping.

Testing is a quantitative process that uses specialized equipment to measure and evaluate a product’s performance, durability, and safety under specific conditions. Examples include crash testing a car to assess safety or subjecting a phone to a temperature test to ensure it functions properly. Testing generates specific data to confirm a product meets its intended functional and regulatory requirements.

Benefits of Inspection and Quality Control in Manufacturing

In a nutshell, inspections help companies carry out operations as per the manufacturing SOPs and deliver safe and high-quality products to their customers. However, let’s look at the benefits of manufacturing inspections in detail:

- Enhanced Quality: Checks and inspections during various stages of production help manufacturers find issues and fix them early on, minimizing the risks of delivering subpar products.

- Reduced Recalls: Recalls threaten profitability, especially in sectors like food manufacturing, where companies lose $10M on average due to recalls. Inspections allow manufacturers to identify issues at the right time, preventing expensive recalls in the future.

- Improved Safety: Manufacturing units have complex products with wires and plugs, welding points, etc., that should be correctly assembled. Through inspections, quality engineers can address issues that may cause safety risks.

- Reduced Maintenance Cost: Regular inspections help detect problems when they are easier and cheaper to resolve. Also, they prevent breakdowns, ensuring machines run smoothly and experience minimum downtime.

- Higher Customer Satisfaction: Consistent checks ensure customers receive high-quality products that meet their expectations. Furthermore, they strengthen brand reputation and boost customer satisfaction in the long run.

- Increased Compliance: Inspections help companies assess adherence to various standards such as product safety guidelines, ISO standards, etc. Identifying and fixing non-compliances saves businesses from penalties and reputational damage.

Types of Manufacturing or Factory Inspections

Typically, three types of inspections are carried out in manufacturing to ensure consistent quality.

1. Pre-production Inspection (Material Inspection)

Pre-production inspection is an initial quality control check conducted before manufacturing begins. It involves testing the raw materials and components, both in terms of quality and quantity. Hence, it is also known as material inspection.

During a pre-production inspection, an inspector checks the expiry dates of the raw materials, performs strength tests for a sample set, and ensures that materials are free from contaminants that may damage the equipment.

Additionally, the inspector also performs a detailed verification of key documents, including the Bill of Materials (BOM) and engineering drawings, to ensure all materials on hand match the project requirements.

👉 Useful Resource: Pre-Production Checklists for Manufacturing Inspections

These checklists will help you and your suppliers inspect raw materials and equipment before starting production.

→ Audit Supplier Checklist

→ Hot Work Permit Checklist

→ Cold Work Permit Template

→ Contract Permit to Work Checklist

→ Supplier Self Assessment Form

→ Pre-Startup Safety Review (PSSR) Checklist

→ ISO 9001:2015 Supplier Inspection Checklist – Manufacturing

» Use These Checklists: Sign up with a 14-day free trial to customize these checklists.

2. In-process Inspection or In-line Inspection

In-process inspection, also known as During Production Inspection (DUPRO) or In-line inspection in manufacturing, is completed in the early stages of production. It aims to identify and address issues and ensure that operations run smoothly.

Two critical checkpoints are often employed:

- First Article Inspection (FAI): This is a detailed and formal inspection of the very first product (or a sample from the first production run). The FAI ensures that the initially manufactured part exactly matches the engineering drawings and design specifications before a full production run begins.

- Golden Samples: Once a first article passes inspection, a perfectly manufactured, fully compliant sample is designated as a “golden sample”. This sample then serves as a master reference that inspectors can use to visually and dimensionally compare all subsequent products throughout the rest of the production run.

Learn More: How Nissin Food leverages GoAudits to digitize in-process, final, and packaging inspections.

During the inspection in production, companies use various inspection methods (such as layered process audits) and equipment for testing and verification. For example, check weighers, metal detectors, and x-ray scanners are used to check products on the conveyor.

👉 Useful Resource: Manufacturing In-line Production Checklists

These checklists will help you assess various aspects of production.

→ GMP (Good Manufacturing Practice) Checklist

→ Manufacturing Process Inspection Checklist

→ Production Quality Control Checklist

→ Pallet Racking Inspection Checklist

→ Layered Process Audit Checklist

→ First Article Inspection Checklist

» Use These Checklists: Sign up with a 14-day free trial to customize these checklists.

3. Final Inspection

As the name suggests, this is the final stage of production inspection, where the finished goods are tested before they reach the customers. The final inspection involves the quality control team testing the product to ensure it meets all the specified manufacturing standards.

To perform a final inspection, most manufacturers use the industry-standard Acceptable Quality Limit (AQL) sampling method, which provides a statistically valid way to determine the maximum number of defects in a randomly selected sample size for a batch to be accepted. The process of AQL looks something like this:

- Determining the Inspection Level: This depends on the batch size.

- Drawing a Random Sample: A specific number of units is randomly pulled from the total batch based on the AQL chart.

- Checking the Sample: Each unit in the sample is checked for both major (critical) and minor (cosmetic) defects.

- Accepting or Rejecting the Lot: The number of defects found is compared against the pre-defined AQL limit. If the number of defects is equal to or less than the limit, the entire batch is accepted. If it exceeds the limit, the whole batch is rejected, and the manufacturer must rework the products or apply for a special waiver.

Thorough final inspection checks help businesses avoid placing low-quality goods on the market, preventing expensive recalls. They also save manufacturers from reputational and financial damage.

SQFI Manufacturing of Food Packaging Checklist: Use this checklist to evaluate if the post-production processes are completed correctly.

Inspection Techniques in Manufacturing

Inspection is a crucial aspect of quality control in manufacturing, and various techniques are employed to ensure products meet specified standards.

- Visual Inspection: This is the most basic and common method, relying on human eyesight to identify visible defects like scratches, dents, or misalignments. It’s often enhanced with tools like magnifying glasses, microscopes, or automated vision systems.

- Dimensional Measurement: This technique ensures that a product’s size, shape, and dimensions conform to design specifications. It uses precision tools such as calipers, micrometers, gauges, and advanced technologies like Coordinate Measuring Machines (CMMs) and laser scanners.

- Non-Destructive Testing (NDT): It assesses a product’s internal integrity without causing damage. Examples include ultrasonic testing to detect internal cracks, X-ray inspection to see inside a component, and magnetic particle inspection to find surface flaws on ferromagnetic materials.

- Destructive Testing: In contrast to NDT, this method involves testing a product to its breaking point to evaluate its strength, durability, and performance under extreme stress. It’s often used for sampling, where a few items from a batch are destroyed to confirm the quality of the whole lot.

Free Factory Production Inspection Report Template

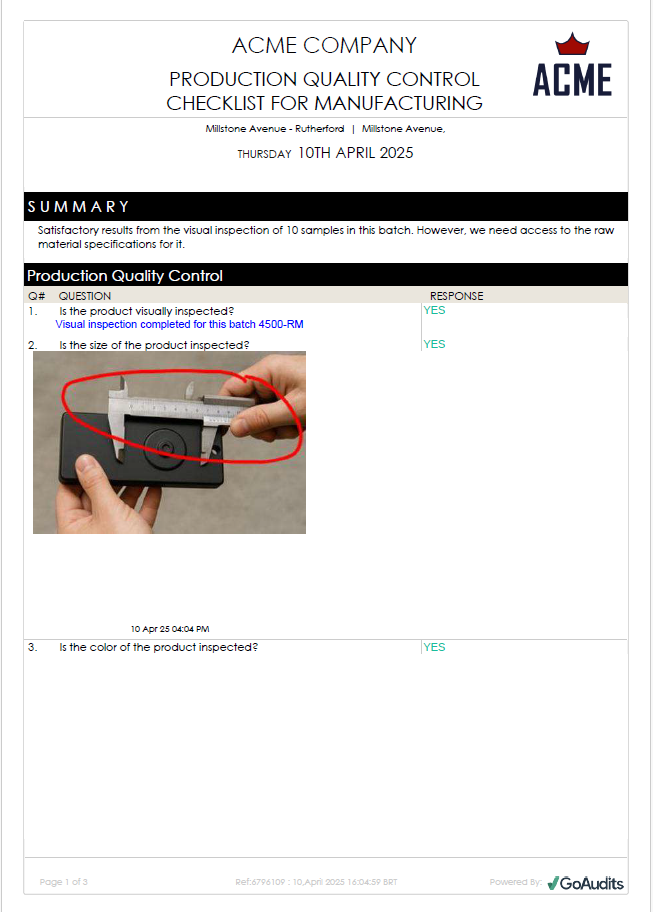

Here’s an example of a manufacturing inspection report template generated with GoAudits:

The above product inspection report template is an example of a checklist-based report generated with GoAudits. Depending on the industry and project complexity, there can be multiple in-process checkpoints.

This may require several individuals to perform inspections at different instances. In such cases, standardizing becomes a challenge. An inspector may miss out on some specific points, or there may be inconsistencies in final reports, depending on who performs the inspection.

Manufacturing checklists can solve this problem. You can create custom checklists based on the process requirements, stage of production, and specific quality standards, and mandate your inspectors to use them. This will ensure they cover all critical checkpoints and report quality consistently in a standardized manner.

Manufacturing and Factory Quality Inspection Checklists

Here are free manufacturing and factory inspection checklists related to regulatory standards and best practices:

- New Miss Log

- 5S Inspection Template

- 6S Inspection Template

- Gemba Walk Checklist Template

- FLSA Audit Checklist

Why Digitize the Manufacturing Inspection Process?

Traditionally, inspections were a tool to detect and fix the identified issues. However, modern manufacturers require more than that. A new study, “Challenges Faced in Modern Quality Inspection”, highlights the key issues plaguing quality control in modern manufacturing, which include the following:

- Preventing defects by anticipating and addressing potential problems before they occur

- Facilitating immediate redressal of issues and preventing defective products from being placed in the market

- Supporting proactive collaboration and cooperation amongst departments and establishing clear communication channels to discuss quality issues

- Including self-inspection to detect defects at their source, minimize errors, and enhance efficiency

- Planning quality inspection in manufacturing and adapting to changes

Here’s how digital production inspection software helps manufacturers tackle these challenges:

- Proactive Inspection Strategies: The standardized digital reports and analytics dashboards help teams identify patterns and trends, enabling them to predict issues before they occur.

- Real-Time Quality Control: Conduct checks on the spot using your mobile devices (even when offline) and share reports instantly with the team. This allows management to address issues quickly and ensure defective products are promptly removed from the production line.

- Streamlined Collaboration and Coordination: Inspectors can provide real-time feedback, propose enhancements, and suggest preventive measures directly within the mobile app.

- Swift Issue Resolution: Assign corrective actions, define priorities, and set due dates for the detected problems, preventing issues from getting further in production.

- Empowering Frontline Workers: To perform self-inspection in manufacturing processes. Ensure they feel accountable and are actively involved in quality assurance, and teams leverage the expertise of those closest to the production process.

- Flexible Inspection Planning and Execution: Modify templates to adapt to changing requirements, such as regulatory standards. Schedule recurring quality inspections in manufacturing and keep track of their completion. Additionally, adjust schedules and optimize resources to conduct efficient inspections.

Here’s how digitizing manufacturing inspections fetched added benefits to HTS, a metallurgical heat-treating service:

Digitizing our audits was the biggest no-brainer for our quality system in the past couple of years. No need to enter data into spreadsheets, the clarity we have gained – this has been a game changer!

Katie Day, Quality Assurance and Metallurgy Manager, HTS

Streamline Manufacturing and Production Inspections With GoAudits

With GoAudits manufacturing software, you have an easy-to-use tool to manage the manufacturing inspection process and promote continuous improvement. Besides simplifying checks, with GoAudits you can:

- Schedule inspections at your preferred frequency

- Create instant inspection reports in one click, customized to your brand

- Delegate corrective actions to individuals in your team or outside your organization

- Use Analytics Dashboards to identify improvement opportunities and make data-driven decisions

- Scrutinize the production process to ensure products meet the manufacturing inspection and quality standards

With a rating of 4.8 stars on Capterra, GoAudits is trusted by some of the biggest names in the manufacturing industry.

» Customer Success Story: How businesses leverage GoAudits to save time and improve operations.

FAQs About Manufacturing Inspection

A factory inspection is the systematic assessment of a factory’s manufacturing processes, QC systems, working environment, and compliance with regulatory and company standards.

Manufacturing audits and inspections vary in scope, objective, approach, and frequency.

1. Scope: An audit comprehensively evaluates a company’s operations and policies. Inspections, however, are restricted to checking products and processes.

2. Objective: Factory audits have a broader objective as they aim to identify areas of improvement, ensure compliance, and maintain standards. On the contrary, manufacturing inspections aim to identify and resolve issues detected before, during, and after production.

3. Method: Depending on the size of the business operations, audits may be delegated to third-party auditors. Whereas, the internal quality control team undertakes inspections.

4. Frequency: Factory audits are conducted annually or biannually. Inspections, on the other hand, are an ongoing process performed regularly to detect and correct defects.

The final inspection in manufacturing refers to checking the finished goods to verify if they adhere to the specifications. It involves testing the randomly selected samples to find non-conformances before the product reaches the market.

A manufacturing inspection plan outlines the procedures and components that must be evaluated at various stages of production to ensure they meet the quality standards.

Depending on the product, stage of production, and what is being evaluated, the following are the methods of quality inspection in manufacturing:

1. Visual Inspection: It involves inspectors checking the products to look for scratches, dents, discoloration, misalignment, or improper assembly.

2. Dimensional Measurement: This method uses tools like calipers, gauges, or micrometers to ensure the components meet the specified dimensions and tolerances.

3. Functional Testing: Techniques like electrical testing, pressure testing, performance testing, etc., are used to ensure that the products operate as required.

4. Non-Destructive Testing: It allows inspectors to evaluate internal properties or hidden flaws using methods like Radiography Testing, Ultrasonic Testing, etc., that do not damage the products.