Industry

Food manufacturing

About

Nissin Food Products Co. Ltd. was established by Momofuku Ando in 1958, who invented the first instant ramen noodle in Japan. In 1970, they established Nissin Foods (USA) in Gardena, California introducing ramen noodles to the U.S consumers. In 1971 the company invented Cup Noodles, and revolutionized the industry by making it possible to package, prepare and serve noodles all in the same container. Today it develops and markets a variety of products under different brands in the US and worldwide.

Location

United States

Dozens of daily checks for food quality & safety

Nissin Foods is the inventor of instant ramen and the manufacturer of the beloved Cup Noodles brand in the US. Their large manufacturing facilities require stringent food quality and safety controls, with dozens of daily checks at different points of the production line.

Parts of the manufacturing quality inspection process were conducted on paper and various documents, making it challenging to collect all data and sign-offs efficiently. Eddie Odie, the Quality Control Manager at Nissin Foods, explains: “Some of this was done by hand, which included a lot of scanning and gathering of signatures. This would cause delays in paperwork being filed or corrective actions taking place.”

The Nissin Foods team therefore decided to digitize their quality checks and GMP (Good Manufacturing Practice) inspections with GoAudits.

Real-time information, quicker corrective actions

The team can now conduct the quality checks using the mobile app or their computer, easily retrieve information anytime, and receive inspection reports and notifications to take action. Required corrective actions are logged directly in the app during the inspection, making it easier to follow-up.

“One of the key features of GoAudits that made the difference for us, is the ability to immediately email the report to the relevant parties,” says Eddie Odie. “This real-time information allows us to address much quicker any issues that are found: after an area is audited, the audit is quickly signed off by the supervisor, and the right corrective actions can be taken as soon as possible. In particular, it helped us respond much faster in the case of product integrity checks.”

Over 96% completion for GMP inspections

Nissin teams now use GoAudits to conduct dozens of daily audits across their manufacturing facilities, in compliance with global food production best practices and standards such as GMP, HACCP and GFSI. This includes audits of different production lines, product quality and integrity checks, packaging inspection, incident logging, inspection of different facility areas, and more.

Because the auditing process is so much more efficient, the teams are able to complete all their planned audits in a timely manner. “Using GoAudits as part of our GMP inspections, we’ve seen a higher completion ratio – without the nagging that sometimes used to be needed to get certain items completed! We are now averaging over 96% completion ratios for just one of our GMP audits,” explains Eddie. “The team enjoys having the information on their computer, not looking for a PowerPoint document to fill out and allowing them to expedite some of the corrective actions.”

Customized reporting and dedicated customer service

The team particularly appreciated the personalized onboarding provided by the GoAudits customer support teams, as well as product customizations.

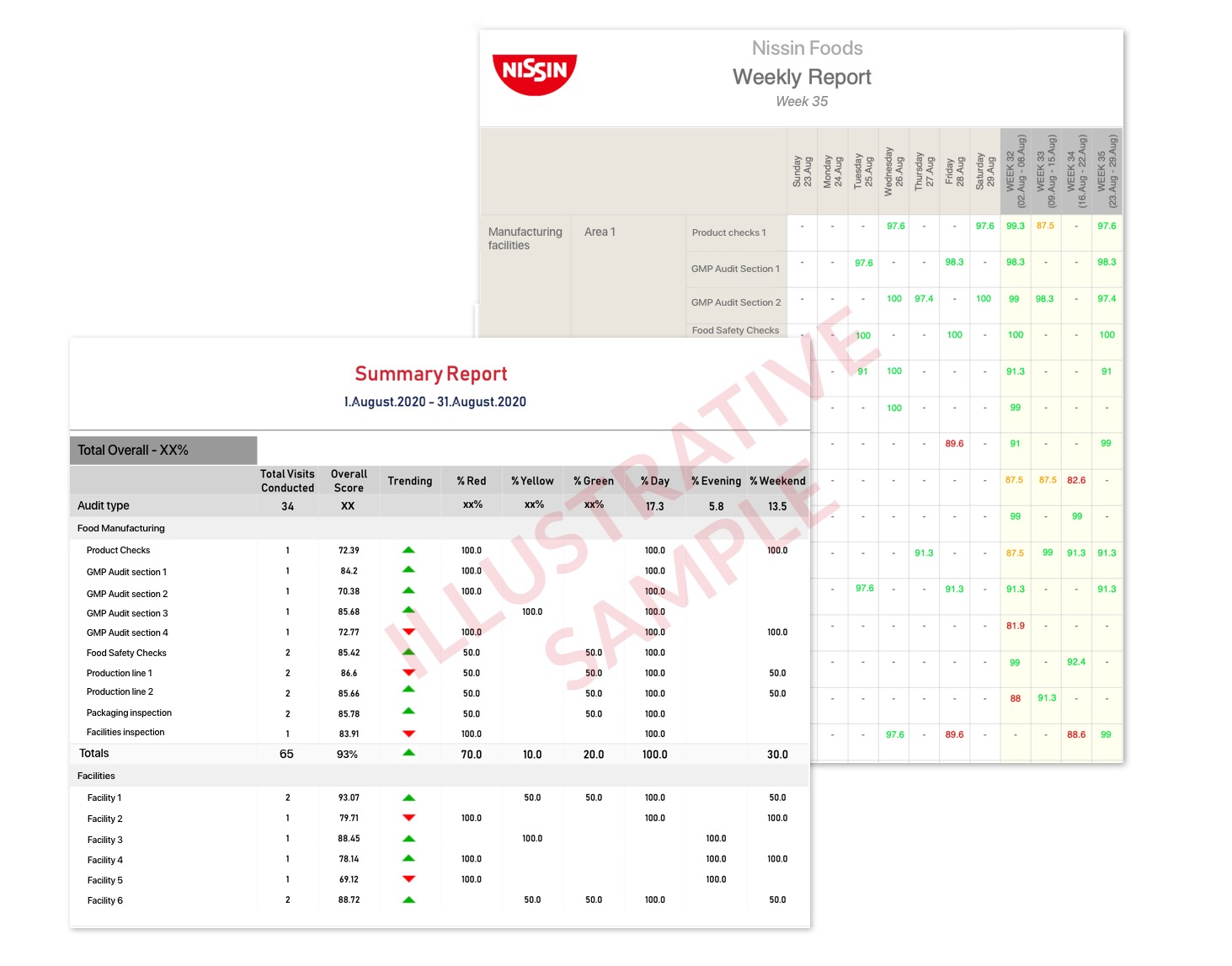

According to Eddie, “In our decision to go with GoAudits, one of the things that I felt was most important was the customization and the dedicated customer service person to help with any issues. Some areas of the system were customized to our specific facilities: for example, matrix reports that I have been able to share across the business and that we have found very useful”.

GoAudits offers many customized reporting formats, including summary reports in the form of a matrix: for a summary of scores across all audit types, facilities and sites, over a certain period of time (e.g. weekly or monthly). These reports enable management to get a high-level overview of recurring issues or trends across the business and make better informed decisions.

Regarding his experience with the GoAudits customer support team, Eddie added: “It has been very enjoyable to work with someone dedicated to helping us get the system off the ground: that made learning something new a whole lot easier for the team. I feel that the GoAudits team are extremely professional. They generally cared about our concerns, and wanted us to be successful in using their platform.”

Read more on GoAudits Inspection Solutions for food & beverage manufacturing.

We are now averaging over 96% completion ratios for our GMP audits. With the ability to immediately email the report to the relevant parties, we get real-time information that allows our supervisors to sign-off corrective actions and resolve any issues much quicker than before.

The GoAudits customer support team are extremely professional, cared about our concerns, and wanted us to be successful in using their platform.

Eddie Odie

Quality Control Manager

Nissin Foods USA

Seeing is believing

We are confident that our product will speak for itself: let us set you up, at no cost.

Try the full platform 14 days with your own data.

- No credit card, no commitment - 100% Free Trial

Seeing is Believing

Get a live demo customized to your unique needs, or get started with a 14-day FREE trial.

- No credit card, no commitment.