Hygiene SOPs are essential in the food industry because they directly impact food safety, customer health, and regulatory compliance. Despite their importance, many food establishments struggle to implement them consistently due to staff turnover, time pressure, manual record-keeping, and poor visibility into daily execution. Paper-based logs are often incomplete, creating compliance gaps and increasing operational risks, which is why digitizing hygiene SOPs through software and digital checklists has become essential. This turns static procedures into trackable processes that improve accountability, simplify audits, and ensure consistent hygiene standards without slowing down operations.

This article will explore the different types of hygiene SOPs, steps to implement them, and free SOP templates.

What are Hygiene SOPs?

A hygiene standard operating procedure (SOP) is a written, step-by-step instruction describing how hygiene, sanitation, and food-handling tasks must be performed to prevent contamination and ensure food safety. Established hygiene SOPs ensure consistent hygiene practices across people, equipment, and work areas.

Why do Food Establishments Need Hygiene SOPs?

Hygiene SOPs ensure consistent product quality and food safety, reduce the risk of foodborne illnesses, and maintain compliance with recognized standards such as HACCP, FSSC 22000, GFSI, BRCGS, IFS, local food safety regulations, and health department codes. They protect brand reputation by minimizing hygiene-related failures, strengthening customer trust, and creating healthier work environments that improve staff productivity while lowering costs associated with spoilage, recalls, absenteeism, and regulatory penalties.

👉 600 million people (nearly 1 in 10) get sick from foodborne diseases, and 420,000 people die annually from contaminated food, while $110 billion is lost in productivity and healthcare due to unsafe food.

Many food businesses struggle without structured hygiene SOPs because execution often varies across shifts, managers lack real-time visibility into whether critical cleaning and sanitation tasks were completed correctly, and paper-based hygiene logs are easily falsified, damaged, or left incomplete. This also leads to weak traceability, making it difficult to provide accurate records during audits, inspections, or customer complaints, which increases legal risk and operational disruption.

👉 GoAudits eliminates these operational blind spots by digitizing the entire inspection and hygiene management process. It replaces paper checklists with a simple mobile app that captures data in real time, even offline, and automatically produces reports with photos, timestamps, user details, and geolocation. You gain accurate, tamper-proof records that strengthen traceability during audits and instant visibility into hygiene performance across sites. With custom checklists, automated scoring, corrective action tracking, and flexible dashboards, GoAudits streamlines compliance, reduces errors, speeds up reporting, and ensures that hygiene SOPs are followed consistently.

Types of Hygiene SOPs in the Food Industry

In the food industry, hygiene SOPs cover everything from personal hygiene to pest control, waste management, and more.

Personal Hygiene SOP

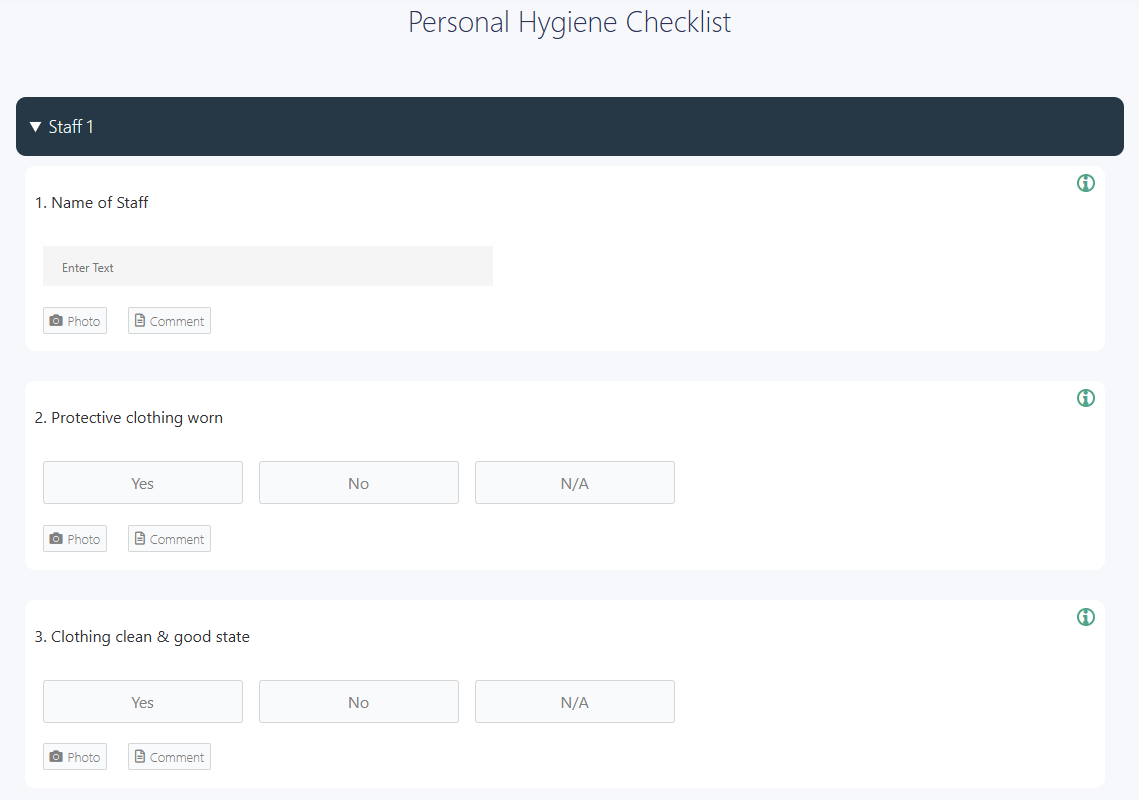

Personal hygiene SOPs define how food handlers must present themselves before and during work. Staff are required to wear clean uniforms, restrain hair, keep nails short and free from polish, and remove jewelry from hands and wrists. Workers must report illnesses, cuts, or skin infections immediately. Any employee showing symptoms of communicable illness must be excluded from food handling areas until medically cleared.

SOP for Cleaning and Sanitation (Facilities, Equipment, and Contact Surfaces)

This SOP governs how dirt, grease, food residues, allergens, and microorganisms are removed from the environment. It establishes fixed cleaning frequencies, approved food-grade chemicals, and defined contact times for sanitizers. It also covers the verification of cleaning effectiveness through visual inspections and microbiological swab testing, ensuring that equipment and surfaces are safe before production starts.

👉 Free Checklists

Kitchen Hygiene SOP

Kitchen hygiene SOPs focus on controlling cross-contamination inside food preparation areas. Raw and cooked foods are handled in separate zones, and color-coded tools are used to prevent the transfer of pathogens. High-touch surfaces such as handles, switches, and worktops are sanitized at set intervals. Environmental hygiene is maintained through proper ventilation, temperature control, and immediate cleanup of spills.

👉 Free Resources

Use these free and customizable checklists to perform kitchen inspections and ensure compliance with hygiene standards.

→ Restaurant Kitchen Cleaning Checklist

→ Kitchen Cleaning Log

→ Kitchen Closing Checklist

→ Kitchen SOP Checklist

→ Kitchen Equipment Maintenance Checklist

→ Home Kitchen Inspection Checklist

→ Kitchen Quality Control Checklist

→ Deep Clean Commercial Kitchen Checklist

Allergen Management SOP

An allergen management SOP prevents unintentional cross-contact between allergenic and non-allergenic products. It requires clear identification of allergenic ingredients, controlled production sequencing, and dedicated or thoroughly sanitized equipment. Packaging and labeling are verified before product release to ensure accurate declaration of allergens, protecting consumers with food allergies from serious reactions.

👉 Free Checklists

Pest Control SOP

Pest control SOPs prevent insects, rodents, and birds from entering food processing areas. Entry points are sealed, waste is tightly controlled, and raw materials are stored off the floor and away from walls. Routine inspections are documented, bait stations are monitored using mapped locations, and trend data is reviewed to enable early corrective actions.

👉 Free Checklists

Food Handling and Storage SOP

This SOP standardizes how food is moved, prepared, and stored. It requires the separation of raw and ready-to-eat foods and limits direct hand contact with finished products. Temperature control is strictly enforced throughout storage and processing. Chilled foods are maintained at or below 5°C, frozen foods at or below −18°C, and hot-held foods at or above 60°C. Stock is rotated using FIFO and expiry-based systems, with clear date and batch labeling.

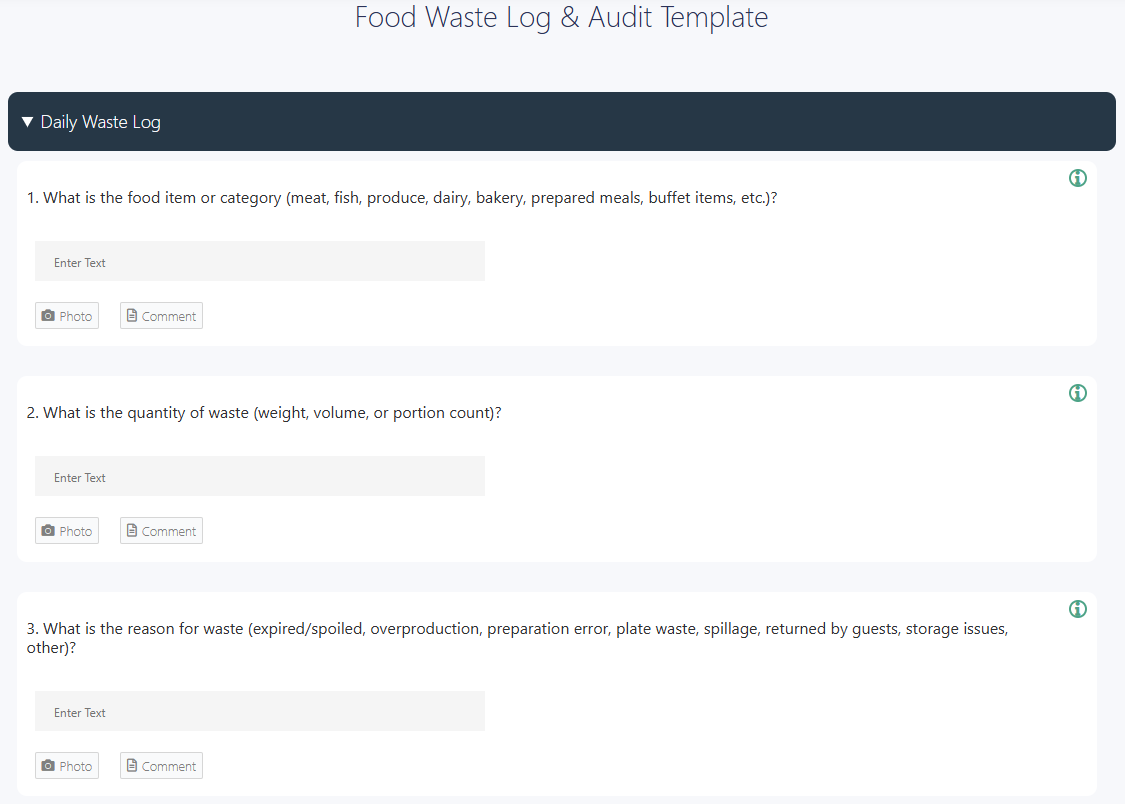

Waste Management SOP

This SOP controls the safe collection, storage, and disposal of waste to prevent contamination and pest attraction. Waste is segregated by type and stored in covered, foot-operated bins. Removal from food areas follows a fixed schedule. Waste containers are cleaned and sanitized daily, and external storage areas are sealed and maintained to prevent environmental contamination.

👉 Perform food waste audits using this free food waste log & template and ensure effective waste management.

Hand Hygiene SOP

Hand hygiene SOPs define when and how hands must be washed. Staff are required to wash their hands at critical points, such as before work, after handling raw food, after using the restroom, and after cleaning tasks. The procedure includes wetting hands, applying antibacterial soap, scrubbing for a minimum of 20 seconds, thoroughly rinsing, hygienic drying, and sanitizing where required.

Steps to Develop & Implement Hygiene SOPs

Below is a step-by-step guide to developing, implementing, and maintaining effective hygiene SOPs.

1. Development Phase

This phase involves building a team that represents all critical functions, conducting a gap analysis, clearly defining the SOP’s scope, writing SOPs, and assigning roles & responsibilities.

Form a cross-functional team

Bring together representatives from operations, quality, safety, and maintenance. This ensures procedures are realistic, compliant, and aligned with how work actually happens on the floor.

Assess current practices

Observe real workflows, review existing cleaning logs, and evaluate hygiene behaviors. Identify gaps, inconsistencies, and high-risk contamination points. This forms the foundation for stronger, risk-based SOPs.

Define scope and procedures

Set clear boundaries for each SOP. Specify what the procedure covers and what it does not. Focus on single-task procedures with clear start and end points to avoid confusion.

Document procedures

Write instructions in direct, action-based language. Use simple sentences, logical sequencing, and consistent terminology. Every step should tell the employee exactly what to do, how to do it, and how often.

Assign roles and responsibilities

Define ownership clearly. Every task must have a responsible performer and a reviewer. This prevents accountability gaps and strengthens audit readiness.

2. Implementation Phase

In this phase, you test SOPs in real working conditions, train employees, and implement the SOPs.

Review and test SOPs

Run real-world trials before full rollout. Measure time, check clarity, and identify friction points. Adjust the SOPs based on actual operator feedback.

Train employees

Deliver targeted, role-based training. Combine short theory sessions with hands-on demonstrations. Confirm understanding through simple competency checks.

Use digital checklists for execution and monitoring

Digital hygiene checklists replace paper logs. They allow real-time tracking, automated audit trails, and instant visibility of missed tasks. This converts hygiene from a manual task into a controlled process.

3. Review Phase

This is the final phase, in which you evaluate the performance of SOPs and update them regularly.

Review SOP effectiveness

Track performance through non-compliance data, internal audits, and hygiene-related incidents. Look for trends rather than isolated failures.

Update and communicate changes

Update hygiene SOPs after audits, incidents, and regulatory changes. Control versions tightly and communicate revisions clearly through brief refreshers and shift briefings.

Digitize Your Hygiene SOPs with GoAudits

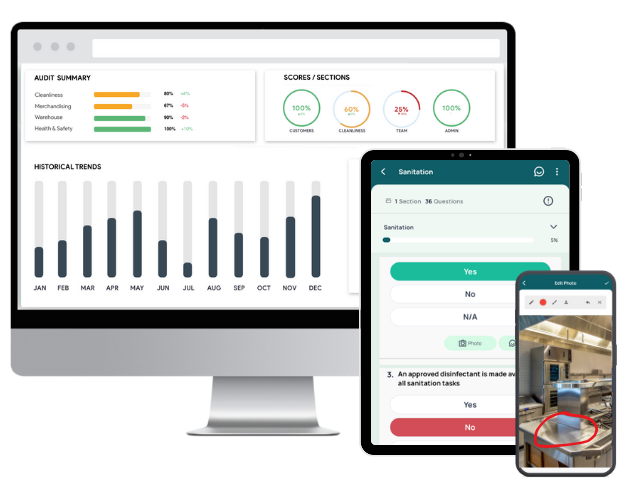

GoAudits transforms hygiene SOPs into clear, mobile-first digital checklists that frontline teams can complete in minutes. Staff follow step-by-step instructions, ensuring every task is performed the same way, every time. Site managers and compliance teams gain real-time visibility into performance across all locations, with instant access to photos, timestamps, signatures, and location data.

Here’s how GoAudits food safety software helps achieve higher hygiene standards, tighter control, and faster issue resolution.

- Access a library of ready-to-use templates, build your own using a simple interface, or upload existing hygiene SOPs and turn them into interactive digital checklists.

- Complete inspections up to 5X faster, even offline, with automatic data sync once back online.

- Capture photos, e-signatures, timestamps, and geolocation for verifiable compliance evidence.

- Generate professional inspection reports instantly after each hygiene inspection.

- Assign, track, and manage corrective actions with clear ownership, priorities, and deadlines.

- Automate workflows, approvals, escalations, and notifications to keep every stakeholder aligned.

- Access smart dashboards with audit scores, performance insights, and recurring hygiene failures & patterns across all locations.

GoAudits helped Independent Food Company by completely transforming their hygiene-audit process across more than 25 restaurant locations. Earlier, the company’s quality team used paper forms and manual reports, and it often took 3-4 days from audit to action. With GoAudits, auditors can document kitchens, supplier sites, and food preparation areas with photos and notes instantly, enabling submission of audit reports on the spot and giving operations teams real-time visibility.

👉 It now addresses 90% of corrective actions within 1-2 days, reducing audit turnaround by 4 times. The built-in dashboards aggregate and score hygiene and compliance data by location, staff, or time period, offering a clear view of hygiene performance.

GoAudits has brought a lot of added value to our work, and it is clear that our QA and Food Safety team efficiency has improved tremendously.

– Eliane E., Quality & Hygiene Manager at The Independent Food Company

Free & Customizable Hygiene SOP Templates

You can sign up for free and start using these food safety audit checklists to perform hygiene inspections and meet regulatory requirements.