Key Takeaways

- A streamlined receiving process is the foundation for accurate inventory and efficient warehouse operations.

- Manual procedures and a lack of standards are some of the biggest challenges in warehouse receiving.

- Digital inspection software like GoAudits helps you standardize, automate, and optimize your receiving process.

Optimizing your warehouse receiving process is a critical step for any business. As the first point of contact for incoming goods, it lays the groundwork for accurate inventory and overall operational efficiency.

According to the 2024 Warehousing and Fulfillment Costs & Pricing Survey, receiving costs range from $2.50 per SKU, $12.91 per pallet, $40.79 per hour, $350 per container, $2.50 to 3.00 per carton. Refining the warehouse receiving procedures can help reduce these costs and prevent inventory discrepancies.

Read on to learn how to transform your receiving area from a potential bottleneck into a powerful asset. We’ll cover everything from key steps and best practices to checklists and templates, helping you streamline your warehouse receiving process for maximum efficiency and profitability.

What is Warehouse Receiving?

Warehouse receiving is the process of accepting incoming goods from suppliers and vendors. It’s the first step in the inventory management lifecycle, where products officially enter your control. It involves a series of critical steps, from unloading and inspection to documentation and temporary storage.

The primary goal of receiving procedures in a warehouse is to ensure that the right products, in the correct quantity and condition, are received and accounted for. Without a solid warehouse receiving process flow, you risk mismatched inventory, billing disputes, and shipping delays.

Who is Responsible for Receiving Procedures in a Warehouse?

The Warehouse Manager or Receiving Manager oversees the entire receiving department, ensuring that warehouse receiving guidelines and warehouse SOPs are followed. They are responsible for staffing, training, and optimizing the process.

Receiving Clerks or Warehouse Receivers handle the day-to-day tasks, from unloading trucks to inspecting and documenting shipments. Their attention to detail is crucial for maintaining accuracy.

Receiving Clerk/Warehouse Receiver’s Roles and Responsibilities

A receiving clerk’s responsibilities in a warehouse typically include:

- Verifying Shipments: Cross-referencing the physical goods with the purchase order and packing slip.

- Inspecting for Damage: Checking for visible damage to packaging and products.

- Counting Inventory: Accurately counting each item to ensure the quantity matches the documentation.

- Documenting Discrepancies: Noting any shortages, overages, or damage on the Bill of Lading (BOL) or receiving report.

- Labeling and Staging: Applying internal labels and moving goods to the designated staging area for putaway.

- Data Entry: Updating the Warehouse Management System (WMS) or inventory records with the received information.

What are the Key Components of an Effective Receiving Area?

A well-designed warehouse receiving area ensures an efficient operation. It’s not just about space; it’s about a strategic layout and the right tools.

- Physical Layout: Includes sufficient docking doors to handle peak shipping times, staging areas for incoming shipments, and inspection zones for detailed receiving inspections and quality control checks.

- Necessary Equipment: This includes material handling equipment, like forklifts, pallet jacks, and hand trucks, barcode scanners/RFID readers for the counting and verification, weighing scales, WMS, and other necessary software.

- Trained Personnel: Staff should be trained on standard operating procedures for warehouse receiving, safety protocols, and the use of all equipment.

Why It is Critical to Optimize Warehouse Receiving and Inspection Process Flow

Here’s why the warehouse receiving and inspection process is critical:

- Boosts Efficiency: A streamlined receiving process reduces the time it takes to unload, verify, and put away goods. This frees up valuable dock space and labor, allowing you to handle a higher volume of shipments.

- Improves Inventory Accuracy: By implementing a robust verification and receiving inspection process, you ensure that your records match your physical stock. This is key for inventory receiving and avoiding stockouts or overstocking.

- Reduces Costs Associated with Errors: A proper receiving inspection process catches miscounted, damaged, or incorrect shipments before they become expensive problems.

- Enhances Customer Satisfaction: Delays or errors in receiving can push back shipping times, frustrating customers. A smooth process ensures products are available for picking and packing promptly.

- Ensures Compliance & Accountability: With a well-documented procedure for receiving goods in a warehouse, you can trace every item back to its origin, essential for quality control, recalls, and regulatory compliance.

Key Steps in the Process of Receiving Goods in a Warehouse

The following steps are involved in a warehouse receiving process operation.

Step 1: Pre-Receiving & Shipment Scheduling

Pre-receiving involves planning for incoming shipments.

- Advance Shipment Notifications (ASNs): Suppliers should send ASNs electronically, providing details like the expected delivery date, contents of the shipment, and an estimated time of arrival.

- Schedule Appointments: for inbound trucks to prevent congestion at the loading docks. This allows your team to prepare for the specific shipment.

Step 2: Shipment Arrival & Unloading

After the driver checks in and is assigned a dock door, the clerk must perform a quick visual receiving and inspection process to check the condition of the trailer’s seal and exterior. The team then unloads the goods using the appropriate equipment and following all warehouse safety protocols.

Loading Dock Safety: Use this checklist to ensure correct maintenance, housekeeping, and compliance with safety procedures in the loading area.

Step 3: Verification & Counting

The receiving team cross-references the physical goods with the packing slip, purchase order, and ASN. For high-value or high-volume items, carry out a blind count for accurate counting. Record all counts on a tally sheet or a mobile app.

Step 4: Receiving Inspection & Quality Control

This step is essential for catching quality issues before they impact your operations or customers.

- Material Receiving Inspection: Check for physical damage, expiration dates, and lot numbers.

- Random Spot Checks: Not every item needs a full inspection, but a random spot check of a few cartons can reveal potential issues.

- Specialized Inspections: For sensitive goods like electronics or food products, conduct a more detailed receiving quality inspection.

Use a digital warehouse checklist instead of a paper one that can get lost or damaged. Your team can easily access these checklists using an inspection mobile app like GoAudits anytime, anywhere, even in areas with low connectivity. After the inspection, mandate your workers to sign off on the inspection, creating an accountability measure.

Step 5: Documentation & Reporting

Once goods are verified and inspected, create a warehouse receiving report to confirm receipt and note any discrepancies. Enter this information into the WMS, officially adding the items to your on-hand inventory.

Use the GoAudits warehouse inspection app to instantly generate a professional material receiving inspection report that can be shared with vendors, accounting, and other stakeholders.

Step 6: Labeling & Staging for Putaway

Print and apply the internal labels with a unique SKU, barcode, or location code. Move the labeled goods to a designated staging area, ensuring they are ready for the putaway team to store in their final location.

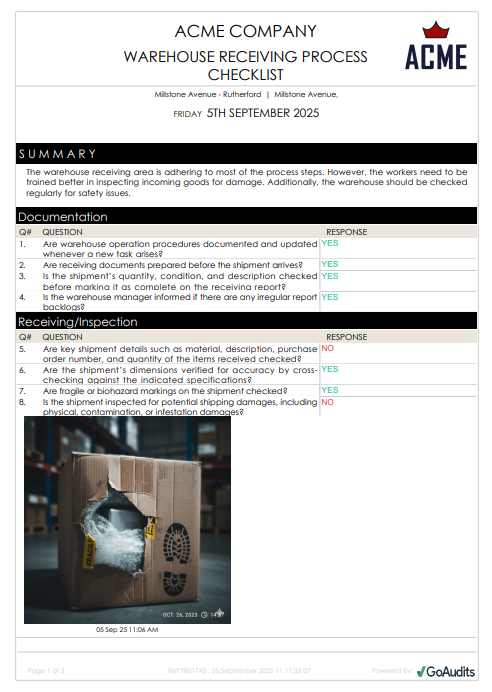

Free Warehouse Receiving Checklist and Report Templates

To help you get started, here’s a comprehensive warehouse receiving checklist and a warehouse receiving report template based on the best practices outlined above. These resources will help you standardize your procedures and ensure nothing is missed.

Free Warehouse Checklists

- Warehouse Receiving Process Checklist

- Warehouse Order Checklist

- Material Inspection Checklist

- Warehouse Storage Checklist

- Warehouse Quality Control Checklist

Warehouse Inspection Templates: Explore our complete library of warehouse checklists.

Free Warehouse Receiving Report Sample

Here’s a free warehouse receiving report template generated using GoAudits inspection software and a receiving process checklist:

Best Practices in Warehouse Receiving & Inspections

An efficient receiving department is a result of more than just following the steps. It’s about a commitment to continuous improvement and embracing the right strategies. Here are the best practices in warehouse receiving:

Implement SOPs for Receiving Goods in Your Warehouse

A robust warehouse receiving standard operating procedures ensures consistency, reduces errors, and simplifies training. Digitize your receiving SOPs to ensure your team members can access them anytime using a mobile app and follow step-by-step instructions.

Moreover, as a manager, you can update the warehouse receiving SOPs whenever required and ensure the changes get synced in real-time, across all devices.

Implement Lean Principles & Continuous Improvement

Lean methodologies in a warehouse focus on eliminating waste, and in the receiving area, waste can take many forms: unnecessary motion, waiting time for trucks, or defects in incoming goods.

By regularly reviewing your warehouse goods receiving process, identify and eliminate these forms of waste, making your operation leaner and more efficient.

Map Out Your Warehouse Receiving Process Flow

Create a warehouse receiving process flow chart to visually map out every step, help you identify bottlenecks, and serve as a clear, easy-to-understand training tool for new employees. This process mapping ensures every team member follows the same standard operating procedure for warehouse receiving and delivers consistent results.

Monitor Key Warehouse Receiving KPIs Consistently

What gets measured gets managed. Warehouse receiving metrics are key to understanding the health of your operation. You should consistently monitor warehouse receiving KPIs, such as:

- Dock-to-Stock Time: The total time it takes for goods to move from the receiving dock to their final storage location, ready to be picked.

- Receiving Accuracy: This KPI assesses the precision of your receiving process by comparing the number of items received against the number ordered.

- Receiving Throughput: This metric measures the volume of goods processed within a specific period (e.g., items per hour, cartons per day).

- Compliance Score: A proprietary KPI that can be generated from your GoAudits platform. It’s a real-time score derived from the completion of your standardized receiving checklists and SOPs. It provides an immediate, tangible measure of how well your team is adhering to established procedures, highlighting areas for immediate improvement and ensuring consistency across all receiving activities.

Cross-Train Receiving Staff & Build Communication

Cross-training ensures that people can perform multiple jobs, maintaining productivity even when someone is absent. Encouraging open communication between the receiving team, inventory control, and putaway teams also prevents misunderstandings and delays, creating a more cohesive workflow.

Prioritize Safety in the Receiving Area

The receiving dock is one of the most hazardous areas in a warehouse. From moving vehicles to heavy loads and equipment, safety must be a top priority. Conduct regular health and safety audits using auditing software to identify and mitigate warehouse risks.

Leverage Technology

The right technology can make your receiving process and the overall warehouse management efficient.

- Warehouse Management System (WMS) provides real-time visibility and streamlines the entire process.

- Barcode and RFID scanners eliminate manual data entry.

- Inspection software like GoAudits replaces paper-based checklists and provides a clear audit trail.

Improve Warehouse Efficiency With GoAudits

GoAudits inspection software is a digital solution to streamline warehouse operations. With advanced features tailored for warehouse processes, it empowers managers to streamline workflows, enhance productivity, and boost profits:

- Train your employees to meet internal and industry standards through custom warehouse checklists and SOPs.

- Schedule as many inspections as you like at your chosen frequency.

- Empower auditors to document and share inspection findings on the go.

- Take prompt actions to address safety issues and other nonconformances.

- Track warehouse operations and inspections in real time through the dashboard.

- Build custom workflows to share audit reports and assign review tasks.

With a rating of 4.8 stars on Capterra, GoAudits is trusted by leading names in manufacturing, retail, and logistics for their warehouse operations.

» GoAudits Reviews: Read how companies leverage GoAudits to meet standards in their warehouse operations.