Food traceability means knowing exactly where every ingredient comes from and where every product goes, throughout every stage of the supply chain. A strong food traceability system helps you verify ingredient sources, monitor quality, and respond fast to recalls or safety issues. Yet many producers still rely on paper logs or disconnected systems, making full traceability slow and error-prone. That’s where food traceability software comes in: it digitizes recordkeeping, automates data capture, and connects every stage of the supply chain for instant visibility and accountability.

In this article, we list the top food traceability apps, common food traceability examples, best practices to establish the system, free checklists, and more.

- 5 Best Food Traceability Software in 2026

- Free & Customizable Food Quality & Safety Checklists

- Common Food Traceability Examples

- Food Traceability System: Key Components & How It Works

- Food Traceability Program: Implementation Steps & How Food Traceability Software Helps

- What is Food Traceability Software?

- How to Choose the Best Food Traceability Software?

- FAQs

5 Best Food Traceability Software in 2026

Here are our top 5 picks of food traceability software.

| Best for | Benefits | Pricing | |

| GoAudits | – Food safety & quality inspections – HACCP compliance – Supplier quality and hygiene assessments – Production, packaging, and storage checks – Restaurant, catering, and retail food safety management | – Enhanced supply chain visibility – Streamlined compliance with food safety standards – Real-time tracking of corrective actions – Reduced manual errors, improved audit accuracy, and consistent data across facilities – Complete transparency and accountability – Strengthened consumer trust | $10 per user per month when billed annually 14-day free trial and personalized demo available |

| Mojix | Complete supply chain visibility, faster recall management, nd compliance automation. | End-to-end transparency, FSMA and ESG compliance, instant recall execution, counterfeiting prevention, waste reduction, and optimized supply chain performance | Contact for pricing |

| Trustwell | Food manufacturing, processing, packaging, and distribution operations | Rapid recall execution, FSMA 204 compliance readiness, supply chain transparency, and enhanced consumer trust | Contact for pricing |

| Craftybase | Complete traceability, compliance, and inventory accuracy across production operations | Rapid recall management, regulatory compliance, food waste reduction, and enhanced transparency and trust across the supply chain | Starting at $20 per month, billed annually |

| Authena | Regulatory compliance, product authentication, quality assurance, supply chain optimization, and sustainability reporting | End-to-end visibility, reduced contamination and counterfeit risks, regulatory readiness, enhanced consumer confidence, and a sustainable food supply chain | Contact for pricing |

1. GoAudits Food Traceability App

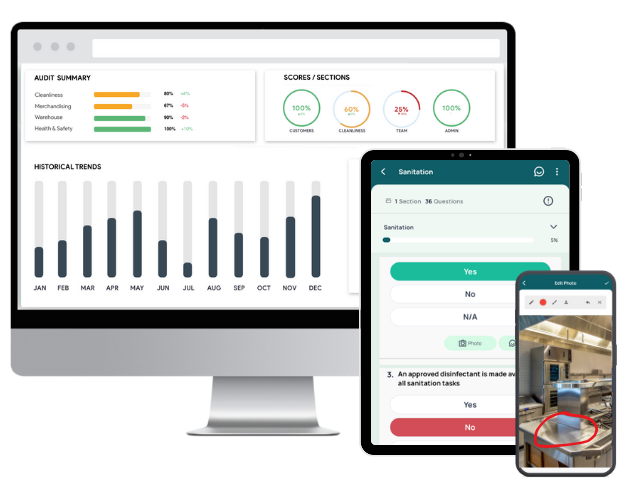

GoAudits food safety software is an inspection-led food traceability and compliance platform for restaurants as well as food manufacturers, processors, and distributors. Run mobile audits, enforce SOPs, and maintain a complete audit trail across all sites – so recalls, verifications, and inspections take minutes, not days.

Best for: Multi-site teams needing consistent execution and audit-ready documentation.

Key features & benefits:

- Customizable GMP/HACCP food safety & quality checklists (or digitize your own forms)

- Offline mobile audits with photos, timestamps, GPS & e-signatures

- Instant reports and centralized audit trails for every site

- Assign corrective actions (CAPA) and track to closure with escalations

- Automated alerts, approval flows, and follow-ups

- Dashboards for trends, scores & recurring issues

- Perform inspections up to 5× faster and ensure real-time visibility across teams

👉 Start with a free trial with food safety & GMP templates or book a 15-minute walkthrough.

2. Mojix Food Traceability Software

Mojix is designed to help you capture and connect every key data element (KDE) and critical tracking event (CTE) in real time. It enables you to ensure product authenticity, execute rapid recalls, meet regulatory requirements like FSMA Rule 204, and maintain operational integrity by integrating blockchain-backed intelligence.

Key features of Mojix:

- Track each product from raw material sourcing through the supply chain.

- Generate FSMA-compliant traceability records for audit readiness.

- Protect and validate product data, ensuring transparency and authenticity.

- Leverage machine learning to detect anomalies, predict demand, and optimize inventory.

- Connect with ERP, POS, and warehouse systems via secure APIs.

3. Trustwell Food Traceability Software

Trustwell enables you to trace every ingredient and product lot both forward and backward across the chain. By digitizing data capture and sharing CTEs, it ensures food safety and compliance and accelerates recall management. You can manage risks, identify root causes of incidents, and maintain transparency with suppliers and consumers alike.

Key features of Trustwell:

- Monitor products and ingredients across every stage of the food supply chain.

- Ensure audit readiness with built-in support for FSMA 204 and GS1 standards.

- Collect and exchange CTEs among suppliers, manufacturers, and retailers.

- Pinpoint and respond quickly to food safety incidents to reduce risk and recall times.

- View, update, and audit traceability data anytime, from field operations to warehouse floors.

4. Craftybase Food Traceability Software for Small Manufacturers

Craftybase is designed specifically for small to mid-sized food manufacturers. It enables you to track ingredients, batches, and finished goods from sourcing to final delivery. By integrating inventory, manufacturing, and traceability data in one intuitive system, it helps you maintain product consistency, reduce waste, and respond rapidly to potential recalls.

Main features of Craftybase:

- Monitor every ingredient and product batch from purchase to sale.

- Calculate and track use-by dates to reduce spoilage and maintain compliance.

- Map production workflows to ensure consistency and accurate material forecasting.

- Optimize stock levels and prevent overproduction or shortages with real-time visibility.

- Gain actionable insights into production costs, margins, and performance.

5. Authena Food and Beverage Traceability Software

Authena leverages IoT, blockchain, and AI to track every product from farm to fork. By providing real-time visibility into product movement and environmental conditions, it enables you to prevent contamination, reduce waste, and meet EU and US regulatory requirements.

Key features of Authena:

- Monitor food products at the unit level through IoT-enabled devices.

- Ensure immutable, tamperproof records across the entire supply chain.

- Capture and analyze KDEs and CTEs for automated audits, predictive insights, and sustainability.

- Enable full transparency and consumer access to verified product information.

- Tracks temperature, humidity, etc., to prevent spoilage and ensure product quality.

Free & Customizable Food Quality & Safety Checklists

GoAudits offers a wide range of food safety audit checklists. You can sign up for free and start using these checklists to perform food safety and quality audits, or you can digitize your food SOPs.

- Food Safety & Hygiene Checklist

- Food Quality Control Checklist

- Food Safety Checklists & Audit Templates

- GMP Audit Checklist Templates

- HACCP-Based SOP Templates

- Vendor Quality Audit Checklist

- Food Manufacturing SOP

- Allergen Control SOP

- Kitchen SOP Checklist

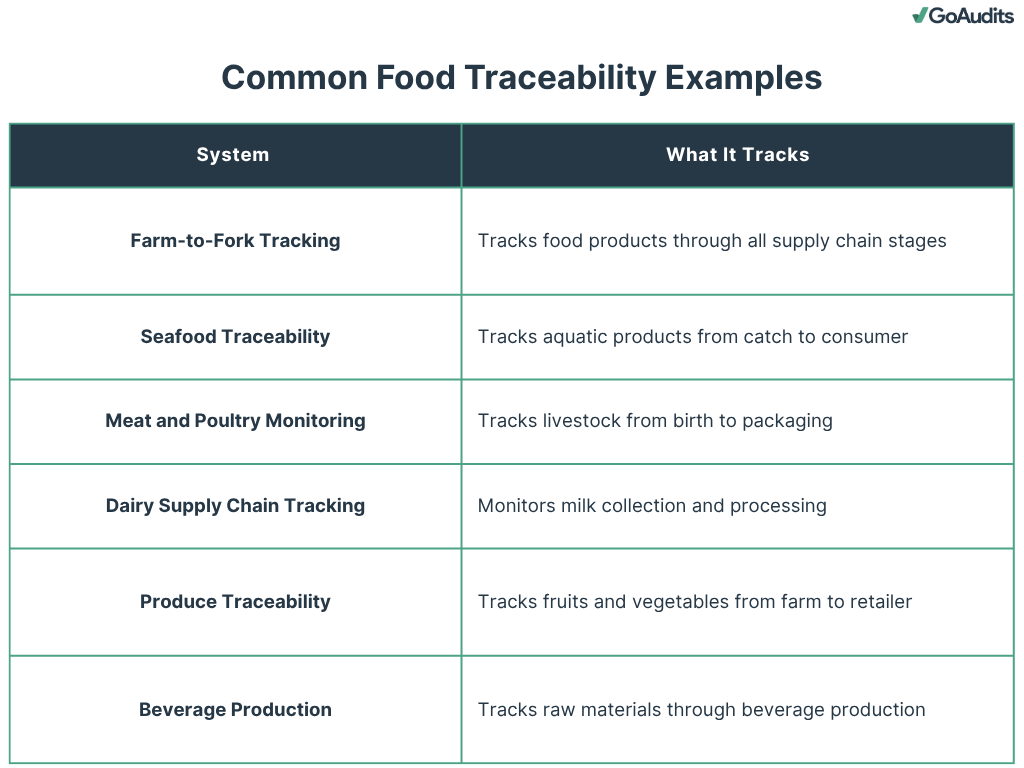

Common Food Traceability Examples

Here are some common examples of food traceability in action:

Farm-to-Fork Tracking

Farm-to-fork tracking offers full visibility of food products as they move through each supply chain stage. This system records data on seed source, farming practices, processing methods, transportation conditions, and retail handling. You can trace any batch back to its origin in seconds, ensuring product safety, authenticity, and transparency for consumers.

Seafood Traceability

Seafood traceability tracks aquatic products from catch to consumer. It records details such as fishing location, vessel identification, harvest time, and processing methods. This data helps verify that seafood comes from legal and sustainable sources. It also prevents issues like seafood fraud and mislabeling, ensuring compliance with import regulations and sustainability standards.

Meat and Poultry Monitoring

In meat and poultry supply chains, traceability systems track livestock from birth through processing and packaging. They capture data on animal health, feed type, slaughtering conditions, and storage environments. You can quickly identify contamination sources or recall specific batches without affecting the entire product line. This ensures food safety, regulatory compliance, and consumer confidence.

Dairy Supply Chain Tracking

Dairy traceability monitors milk collection points, transportation temperature, pasteurization processes, and packaging details. Accurate tracking ensures freshness, reduces spoilage, and verifies that dairy products meet safety and quality standards. It also helps you confirm the ethical sourcing of milk from certified farms.

Produce and Fresh Food Traceability

Fresh produce traceability tracks fruits, vegetables, and other perishables from farms to retailers. It records information about cultivation methods, pesticide use, harvest dates, and cold chain management. This data helps prevent contamination, manage recalls efficiently, and assure consumers of product quality and sustainability.

Beverage Production

Beverage traceability systems follow raw materials like water, sugar, and flavorings through each stage of production. These systems record quality checks, batch codes, and packaging details. With this visibility, you can ensure consistency, verify ingredient origins, and maintain compliance with safety regulations.

Food Traceability System: Key Components & How It Works

A food traceability system ensures transparency and safety throughout the food supply chain. It helps you track every step a food product takes. Here are its 5 key components and how they play a role in this system.

1. Product Details and Ingredient Identification

Traceability begins with precise product identification. Each item, raw material, and ingredient is assigned a unique identifier such as a barcode, QR code, or RFID tag. These identifiers record key information, including:

- Product name and description

- Batch or lot number

- Origin and supplier details

- Processing and packaging dates

It helps you link every ingredient to its source.

2. Data Capture and Management at Each Stage

Data collection happens at every point in the supply chain. Using technologies like sensors, IoT devices, and mobile scanners, you can automatically capture information such as:

- Temperature and humidity during transport

- Time and location of each transaction

- Handling or storage conditions

All captured data is securely stored in a centralized traceability database. This ensures consistency, prevents data loss, and allows authorized users to access and update records in real time.

3. Data Sharing and Information Exchange Along the Supply Chain

Efficient traceability relies on transparent information exchange among all stakeholders, including farmers, processors, distributors, and retailers. Cloud-based platforms and blockchain technology make it possible to share verified data instantly.

You can:

- Access product data anytime

- Confirm supplier compliance

- Reduce delays and issues quickly with real-time analytics

- Improve coordination between partners

- Gain insights into supply chain performance

- Monitor product movement and detect irregularities

- Predict potential disruptions proactively

- Generate automated reports to meet regulatory standards

- Monitor key performance indicators (KPIs) effectively

👉 GoAudits provides an overview of performance across all sites, teams, and categories. You can drill down from high-level summaries into individual inspection reports, track task completion, and analyze trends or recurring issues. Smart scoring and historical data views help you identify problem areas and implement timely corrective actions. With automated notifications, task tracking, and flexible workflows, GoAudits ensures that every issue is addressed, reported, and resolved. This allows you to make informed decisions, maintain compliance, and continuously improve operational standards.

4. Product Tracing

In the event of a recall or safety issue, product tracing enables fast and accurate backward and forward tracking. You can trace a defective batch back to its origin or track affected shipments to specific retailers. This minimizes losses, protects consumers, and strengthens brand credibility.

5. Authentication and Verification

Authentication ensures that the data and products within the system are genuine and tamper-proof. Using digital signatures, blockchain validation, or QR code verification, you can confirm the authenticity of product information. Regular audits and system validations further enhance trust and compliance.

Food Traceability Program: Implementation Steps & How Food Traceability Software Helps

Follow the steps below to implement a food safety program effectively.

Define Your Business Objectives

Begin by clarifying what you aim to achieve through traceability. Objectives may include regulatory compliance, faster recall management, improved transparency, or enhanced consumer confidence. Defining these goals helps you design a traceability framework aligned with your operational needs and risk profile.

Food traceability software lets you set measurable KPIs, such as tracking accuracy or recall response time, and monitor progress in real time.

Map Your Supply Chain

Create a detailed map of your supply chain. Identify each participant, the flow of materials, and the data exchanged at every step. This ensures visibility across every link in the chain.

Food traceability software integrates data from suppliers, manufacturers, logistics partners, and retailers into a unified dashboard, providing a single source of truth.

Identify Critical Tracking Points (CTPs)

Determine where data must be captured to maintain traceability. CTPs often include receiving, processing, packaging, storage, and distribution stages. Capturing accurate data at these points ensures quick root-cause analysis in case of contamination or recall.

Automated data capture through barcodes, RFID tags, or IoT sensors ensures accuracy and eliminates manual errors at every CTP.

Choose the Right Technology

Select technologies that suit your product type, supply chain complexity, and budget. RFID tags, QR codes, and barcodes are common tools for real-time tracking and data sharing. Ensure that your technology can integrate with existing ERP or quality management systems.

Food traceability systems support multiple technologies, offering seamless integration with your operational infrastructure for end-to-end visibility.

Set SOPs and Train Your Teams

Develop standard operating procedures (SOPs) that define how data should be collected, recorded, and verified. Proper training ensures that all stakeholders understand their roles and maintain consistency in data handling.

Training modules and automated workflows within the software guide users through proper data entry and validation processes, ensuring compliance with SOPs.

Test and Scale

Start small and implement the traceability system in a single facility or for a specific product line. Evaluate performance, identify gaps, and refine your processes before a company-wide rollout.

Simulations and test environments in the software let you analyze real-time data, detect inefficiencies, and optimize before scaling.

Build Audit Trails

Maintain a secure record of every transaction and data entry to ensure traceability and accountability. Audit trails enable you to verify data accuracy and demonstrate compliance during inspections.

👉 GoAudits enables you to log every action, e-signatures, timestamps, geolocation, and user information, creating a record of all activities. Auditors can attach photos and annotate them directly in the app, providing visual evidence that is permanently linked to the audit entry. Reports are automatically generated after each audit with all supporting data. Reviewing historical trends, recurring issues, and corrective actions becomes easy. Notifications, task assignments, and workflow actions are recorded, offering a full trail that ensures accountability and thorough compliance verification.

Establish Recall Procedures

Create clear procedures for product recalls, including communication protocols and response timelines. A well-defined recall process minimizes damage and ensures quick corrective actions.

Food traceability software can instantly trace affected batches, generate recall lists, and automate notifications to relevant parties, significantly reducing response time.

Monitor and Improve

Continuously monitor traceability performance and collect feedback from all stakeholders. Use insights from data analytics to refine procedures, strengthen supplier relationships, and improve overall system efficiency.

Analytics dashboards provide real-time performance metrics and trend analysis, helping you identify recurring issues and implement preventive measures.

What is Food Traceability Software?

Food traceability software is a solution that helps track and record the movement of food products and ingredients and ensure full visibility throughout the supply chain. It captures essential data and enables companies to monitor where every ingredient originates, how it’s processed, and where it ends up. This assists in quickly identifying contaminated or recalled items, reducing food safety risks, and ensuring compliance with frameworks like the FDA’s Food Safety Modernization Act (FSMA 204) and GS1 standards.

Key Features & Benefits of a Food Traceability App

- Track every product from source to shelf with unique barcodes and lot numbers, enabling instant backward and forward traceability for full visibility at any stage.

- Provides live updates on product movement, temperature, and handling using IoT sensors, preventing spoilage and ensuring product integrity.

- Instantly identify affected batches and initiate targeted recalls, reducing response time, minimizing losses, and maintaining product safety and quality.

- Keep documentation organized and up to date with automated reports, digital audit trails, and compliance checklists aligned with food safety standards like FDA, FSMA, and HACCP.

- Optimize inventory rotation, reduce overstocking and spoilage, and streamline logistics with accurate, data-driven insights.

- Detect potential risks early, prevent safety breaches, and strengthen brand credibility by showing transparency and accountability to consumers.

How to Choose the Best Food Traceability Software?

Choosing the right food traceability software can make or break your compliance, efficiency, and customer trust. Here’s how to find the best fit for your business:

Assess Your Business Needs and Regulatory Requirements

Start by defining what you need to track: ingredients, batches, suppliers, or finished products. Understand the regulations you must follow, such as the FDA’s FSMA or EU food laws. The software should help you stay compliant while improving visibility across your supply chain.

Compare the Cost and Your Budget

Don’t overspend on features you won’t use. Compare pricing models: subscription, per-user, or per-location. Choose software that fits your budget but still offers scalability as your business grows.

Read Customer Reviews and Testimonials

Check what other food businesses are saying. Reviews reveal real-world performance, from data accuracy to ease of use. Prioritize software with strong ratings for reliability and customer support.

Look for User-Friendly, Cloud-Based Solutions with Strong Security

Opt for software that’s intuitive and easy to navigate. A cloud-based platform allows real-time data access from anywhere, ideal for multi-location operations. Ensure it includes strong data encryption, access control, and regular security updates.

Leverage Free Trials and Demos

Before committing, test the software. Free trials and demos help you see how it integrates with your existing systems and how easy it is for your team to use.

Ensure 24/7 Customer Support Availability

Issues can arise anytime. Choose a vendor that offers round-the-clock support through chat, email, or phone. Quick assistance minimizes downtime and keeps your operations running smoothly.

FAQs

Food traceability is important because it allows producers and regulators to track every step of a food product’s journey, from source to shelf. It helps identify contamination sources quickly, ensuring unsafe products are removed before they harm consumers. Traceability also builds trust by proving food authenticity, supports compliance with safety standards, and minimizes financial losses during recalls.

Key metrics for measuring food traceability system performance include data accuracy, trace time, system coverage, and recall response speed. Data accuracy ensures reliable tracking information. Trace time measures how fast a product can be traced through the supply chain. System coverage shows how many suppliers and processes are included, while recall response speed evaluates how quickly contaminated items can be isolated and removed.

Food traceability tracks a product’s path through every stage of production and distribution, ensuring transparency and accountability. Food recall, on the other hand, is a reactive action taken when a safety issue is detected. While traceability helps prevent problems through monitoring, a recall helps correct them by removing affected products from the market. Both work together to protect consumer safety.

The FDA’s food traceability requirements, outlined under the Food Safety Modernization Act (FSMA) Rule on Traceability, mandate that companies keep detailed records of key data elements (KDEs) at critical tracking events (CTEs). These records must show how food moves from origin to destination. The goal is to enable rapid tracking during contamination events, strengthen supply chain transparency, and enhance overall food safety.