Are you confident that your food business would pass an unexpected EHO inspection if it happened today? Environmental Health Officer (EHO) inspections usually happen without prior notice to ensure food businesses meet food safety and hygiene standards. These inspections assess food handling, storage, and preparation practices to prevent contamination and foodborne illnesses, ensuring the food products are safe for consumption. Being prepared for EHO inspections at all times is essential for food businesses. It not only helps in passing these inspections but also in maintaining and enhancing customer trust and business reputation through high hygiene ratings. However, preparing for EHO inspections is not an easy task.

We have created a list of essential steps you must take to prepare for the next EHO inspection. You’ll also find free and customizable food and safety checklists that can help you prepare for these inspections.

- Environmental Health Inspections: An Overview

- EHO Ratings & Impact on Your Business

- Key Areas of Focus During EHO Inspections

- How to Prepare for EHO Inspections in 7 Steps?

- Prepare for Environmental Health Inspections with GoAudits

- Free EHO Inspection Checklists & Other Templates

- Common Reasons for EHO Visits

- Handling Non-Compliance: Legal Notices and Their Implications

- What if You’re Not Satisfied with the EHO Rating?

Environmental Health Inspections: An Overview

Environmental Health Officer (EHO) inspections are an evaluation conducted by EHOs to ensure that food businesses comply with local food safety and hygiene regulations. EHOs are tasked with implementing and overseeing food safety laws to prevent health hazards in food-related businesses.

Are EHO audits mandatory?

Yes, EHO inspections are mandatory for food businesses. They are part of the regulatory framework that ensures public safety and hygiene standards are maintained. Businesses must comply with these inspections, which can be scheduled routinely or triggered by specific complaints or incidents.

What to Expect During an EHO Inspection?

During EHO inspections, you should expect a thorough review across several key areas. These include food handling practices, premises and environment, and food safety management systems (FSMS). The cleanliness and the safety of food contact surfaces and equipment are also assessed during EHO inspections.

How EHOs Assess Compliance?

An Environmental Health Officer is responsible for promoting environmental and public health through the enforcement of legislation related to food safety, public health, and environmental protection. EHOs inspect food businesses to ensure compliance with health and food safety standards, focusing on food practices, premise conditions, and food safety management systems.

EHOs take photographs and collect samples to assess whether you comply with food safety and hygiene standards. They directly observe food handling and storage practices and even interview staff to assess their knowledge. They also review documents and records such as staff training certificates, risk assessments, and maintenance records like gas safety certificates.

When Can an Environmental Health Officer Visit?

EHOs can visit your premises at any time without prior notification. Their visits can be triggered by various reasons such as routine checks, customer complaints, or follow-ups from previous inspections. Legally, businesses must allow EHOs to conduct their inspections upon arrival.

How Often Do EHOs Visit?

The frequency of EHO visits varies based on the risk category of your food business. High-risk businesses may see inspections every six months, whereas lower-risk businesses might be inspected every two to three years.

EHO Ratings & Impact on Your Business

The Food Hygiene Rating Scheme (FHRS) is a regulatory tool that helps consumers make informed choices about where to eat or shop for food based on hygiene standards. This scheme is run by local authorities in partnership with the Food Standards Agency (FSA) across the UK. Based on inspections, businesses are rated on a scale from 0 to 5.

| Ratings | Hygiene Standards |

| 5 | Very good |

| 4 | Good |

| 3 | Generally satisfactory |

| 2 | Some improvement required |

| 1 | Major improvement required |

| 0 | Urgent improvement required |

The visibility of hygiene ratings can significantly impact customer perceptions and trust. In Wales and Northern Ireland, it’s mandatory for businesses to display their hygiene ratings at their premises, while in England, it’s voluntary but encouraged. High ratings can help businesses attract more customers. Conversely, low ratings can deter customers and negatively impact a business’s reputation.

Key Areas of Focus During EHO Inspections

Here are the three focus areas of EHO inspections.

Food Handling and Storage Practices

Ensuring that food is handled and stored correctly is a primary focus during an EHO inspection. This includes the following:

- Personal Hygiene: Regular handwashing, proper use of gloves and hairnets, and maintaining clean uniforms are critical.

- Staff Training: Employees should be well-trained in food safety practices and emergency responses.

- Food Preparation: Monitoring cooking temperatures, ensuring food is reheated properly, and preventing cross-contamination, especially with allergens, are essential.

- Temperature Controls: The proper functioning of refrigerators and freezers to maintain correct storage temperatures is checked.

- Allergen Management: Clear labeling and avoidance of cross-contamination are necessary to manage allergens effectively.

Structural Condition of the Food Premises

The physical condition of the premises is another key area of EHO inspections:

- Cleanliness and Maintenance: Ensuring that the facility is clean, well-maintained, and free of clutter.

- Ventilation: Proper ventilation systems must be in place to prevent odors and condensation.

- Pest Control: Effective and regular pest control measures must be implemented to avoid infestations.

- Waste Management: Proper disposal systems and regular waste removal are essential to maintain hygiene.

Food Safety Management Systems

The organization and documentation of food safety practices are essential:

- Documentation: Keeping detailed records of food safety procedures, including temperature logs and staff training records.

- Staff Knowledge: Employees must understand and implement food safety management practices.

- Compliance Procedures: Regular audits and checks should be conducted to ensure ongoing compliance with food safety regulations.

How to Prepare for EHO Inspections in 7 Steps?

Here’s a comprehensive guide to preparing effectively for these inspections, ensuring compliance, and possibly boosting your establishment’s reputation by achieving a high hygiene rating.

1. Understand the Role of EHOs and the EHO Audit Criteria

EHOs are responsible for assessing various aspects of your food business to ensure compliance with food safety standards. Their evaluations focus on how food is handled, the cleanliness of premises, and the management systems in place to maintain food safety. Regular inspections might be scheduled based on the risk level of your business, with more frequent visits for higher-risk establishments.

2. Implement a Food Management System

Having a robust food safety management system is essential. This should include clear documentation of your processes, regular staff training, and adherence to food safety legislation. Effective management systems not only help during EHO inspections but also ensure day-to-day compliance.

3. Prepare Your Facilities and Premises

Ensure that your premises are in good condition. This includes structural integrity, cleanliness, and appropriate waste management systems. Pay attention to pest control and proper storage to prevent contamination. Regular checks and maintenance can help address potential issues before they become significant.

4. Train Your Staff for Unexpected EHO Audits

Staff training is an essential preparatory step for EHO inspections. Your team should be well-versed in personal hygiene, food handling, and cleanliness practices. Regular training sessions can help keep everyone updated on the latest food safety protocols and encourage compliance.

5. Use Environmental Health Inspection Checklists for Self-Assessments

Self-audits are a proactive way to prepare for EHO inspections. Use detailed checklists to review your establishment’s compliance with food safety practices, including food handling, storage, and preparation areas. This can help identify areas that need improvement before an official inspection occurs.

👉 You can use this free environmental health inspection checklist to conduct thorough self-assessments and ensure compliance with health and safety standards.

6. Take Corrective Actions

Post-inspection, thoroughly review the findings and start implementing corrective actions quickly. It involves prioritizing the issues identified during the inspection based on their impact and urgency. For effective corrective action, businesses must ensure that the root causes of non-compliance are addressed, not just the symptoms. This can be achieved by effectively tracking corrective actions, revising procedures, training employees, or making necessary changes to equipment or materials.

7. Monitor and Review Performance

Continuously monitor and review your food safety practices. This could include tracking temperature controls, cleanliness, and employee hygiene practices. Regular reviews can lead to immediate corrective actions, enhancing overall compliance.

8. Document Findings for Continuous Improvement

Documentation is not only crucial for compliance but also for tracking improvements over time. Keep detailed records of audits, training sessions, and any corrective actions taken.

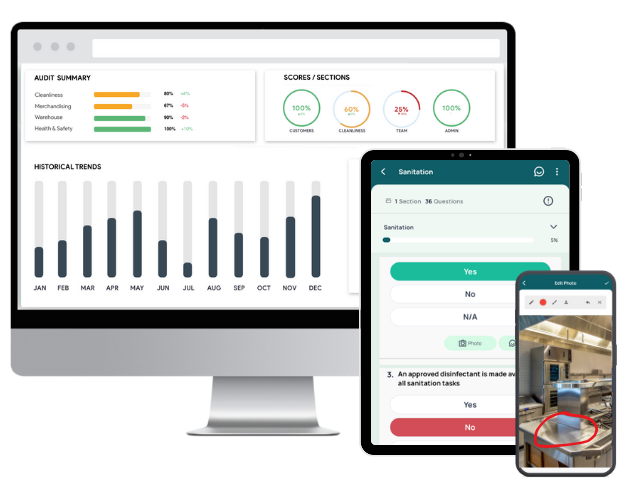

Prepare for Environmental Health Inspections with GoAudits

GoAudits food safety software is an all-in-one auditing platform designed to simplify compliance while improving operational standards. With mobile inspections, automated reports, corrective action tracking, and powerful analytics, you can reduce paperwork and focus on creating safer, compliant environments.

- Access ready-to-use checklists tailored to health and safety requirements. Customize them to your business needs or upload existing ones, and we will convert them for you at no extra cost.

- Conduct audits and inspections on any device, even offline, with features like photo evidence, annotations, e-signatures, timestamps, and geolocation.

- Automatically generate branded, professional inspection reports the moment an audit is complete. Share them instantly with your team for quicker decision-making.

- Assign issues to team members in real time. Track priorities, due dates, and status updates through a centralized dashboard to ensure accountability and timely resolution.

- Set up reminders, approvals, and escalation rules to keep the right people involved. Automate notifications so nothing slips through the cracks during or after inspections.

- Gain a comprehensive view of compliance performance across teams and locations. Spot recurring issues, analyze trends, and track improvements with smart dashboards.

Free EHO Inspection Checklists & Other Templates

Explore our library of free food safety checklists and restaurant checklists, including EHO inspection checklists. Sign up and easily customize these checklists to get started with efficient internal audits.

- Food Safety & Hygiene Checklist

- Food Premises Self-Inspection Checklist

- Hygiene Checklist for the Food Industry

- Food Facility Self-Inspection Checklist

- Restaurant Safety Checklist

- ISO 22000 Food Safety Checklist (FSMS)

- Food Safety Kitchen Inspection Checklist

- Food and Beverage Audit Checklist

- Pest Control Checklist for the Food Industry

Common Reasons for EHO Visits

Here are the three common reasons for EHO visits:

Routine Inspections Based on Risk Levels

EHOs conduct routine inspections based on the risk level associated with a food business. The frequency of EHO inspections can vary depending on the business type and its previous compliance record. For instance, high-risk businesses might be inspected more frequently, potentially every six months, while lower-risk premises might see longer intervals between inspections.

Follow-ups from Previous Inspections

If a previous inspection has identified issues, EHOs will revisit to ensure that all necessary corrections have been made. This follow-up EHO visit assesses whether the business has addressed the concerns raised effectively and whether it now complies with the required standards.

Complaints and Random Checks

EHOs also visit in response to consumer complaints or as part of random checks. EHO inspections are essential for addressing specific issues reported by the public or for ensuring ongoing compliance across the board. Complaint-driven EHO inspections are often prioritized to tackle potential immediate health risks.

Handling Non-Compliance: Legal Notices and Their Implications

Failing an EHO inspection can lead to a range of consequences, depending on the severity of the offense. Repeated non-compliance or serious breaches can result in significant fines, prohibition orders, or even criminal charges. Understanding the types of notices and how to respond is crucial for any food business aiming to maintain high standards of hygiene and avoid penalties.

Hygiene Improvement Notice

This notice is issued when issues are identified regarding the food preparation area or non-compliance with food hygiene standards. A hygiene improvement notice demands specific improvements within a fixed timeframe, typically 14 days or less, if the issues are severe and pose an imminent risk to consumers. Failure to comply can result in fines or more severe consequences, such as closure. You should keep the EHO informed of the progress. You must immediately contact them if you’re unable to comply within the specified time.

Emergency Prohibition Notice

This is served when there is an immediate health risk, requiring parts or the entire business to cease operations. Emergency prohibition notice remains in effect until the issues are rectified and verified by the EHO. Immediate action to address the issues specified is necessary to prevent long-term closure.

Seizure and Detention Notice

If food products do not meet safety standards imposed by a country, a legal notice may be served to seize and detain them. Businesses should cooperate fully and take steps to ensure all products comply with safety regulations.

Steps to Take If You Receive a Notice

- Understand the details and the specific violations noted.

- Implement the required changes or improvements as specified in the notice.

- Keep a record of what was corrected and any correspondence with the EHO.

- Once improvements are made, you can request a follow-up inspection to get the notice lifted.

- Consider seeking legal advice if you believe the notice is unjust or incorrect. You have the right to appeal against certain decisions.

What if You’re Not Satisfied with the EHO Rating?

Here’s a step-by-step guide on what to do if you’re not satisfied with your EHO rating:

Step 1: Understand the Rating and Initial Contact

Before initiating a formal appeal, it’s advised to first contact the EHO who performed the inspection. It will help you understand the specific reasons behind the assigned rating. Discussing these details can provide insights into whether there might have been misunderstandings or overlooked elements during the inspection.

Step 2: Preparing to Appeal

If, after discussion, you still believe the rating to be unfair, you can proceed with a formal appeal. The appeal must be lodged within a specific timeframe, which can vary by location. Typically, you have 14 to 21 days from the date of receiving your rating to submit an appeal. It’s important to check with your local authority for the exact timeframe applicable to your area.

Step 3: Submitting the Appeal

The appeal can usually be submitted in writing or via a form provided by your local authority. This form should be filled out with details of your dispute and any evidence you might have that supports your case for a reassessment of the rating.

Step 4: Right to Reply

Alongside the appeal, you also have a ‘right to reply’. This is an opportunity to explain to potential customers, via the authority’s website, the circumstances that might have led to the lower rating, and what has been done to address the issues identified during the inspection.

Step 5: Requesting a Revisit

If you’ve made significant improvements based on the feedback from the initial inspection, you can request a revisit to reassess your hygiene standards. However, keep in mind that there’s usually a minimum wait period before a revisit can occur (often three months unless major structural or equipment changes have been implemented).