Hygiene compliance in food production starts with one nonnegotiable requirement: proof that every process, surface, and facility meets strict regulatory standards. While hygiene standards apply across industries, the food & beverage sector is under particularly tight scrutiny because even a single oversight can compromise consumer safety and brand credibility. Yet many food businesses still rely on manual checklists, paper logs, and fragmented inspections that make it difficult to maintain traceability and increase contamination risk. Hygiene inspections are designed to close those gaps, but their effectiveness depends on how they are planned, executed, and monitored.

This article lists the role of hygiene audits in the food industry, key areas assessed, steps to perform them, and free checklists.

- What are Hygiene Inspections?

- Key Areas Assessed During Hygiene Audits

- Steps to Perform Internal Hygiene Checks

- Perform Hygiene Inspections 5X Faster with GoAudits

- Free & Customizable Hygiene Audit Checklists

- Common Issues Identified During Hygiene Inspections

- How Hygiene Training Works With Daily Hygiene Inspections

- FAQs

What are Hygiene Inspections?

Hygiene inspections are systematic checks of premises, people, equipment, and processes to verify that cleanliness, sanitation, and related safety requirements are being met, usually against legal, regulatory, or internal standards. They aim to identify unhygienic conditions, potential sources of contamination, and nonconformities so that corrective actions can prevent illness, product contamination, and reputational or legal consequences.

Hygiene audits usually involve observing operations, checking records, interviewing staff, and inspecting infrastructure (food contact surfaces, washrooms, ventilation, waste handling, and storage conditions) against defined criteria.

Who Needs to Perform Hygiene Audits?

Businesses such as food establishments, healthcare facilities, schools, factories, and other workplaces, as required by public health or occupational safety law, must perform

These businesses are also expected to perform internal hygiene inspections as part of their own food safety, infection prevention, or workplace health and safety management systems.

How Often are Hygiene Inspections Performed?

Official inspections by authorities are typically risk‑based: higher‑risk operations in restaurants, healthcare, and high‑risk manufacturing facilities are inspected more often than low‑risk ones. Audit intervals can range from several times per year to every few years, depending on local regulations and compliance history.

Internal hygiene inspections should be more frequent and defined by the organization’s risk profile and procedures, often ranging from daily line‑level checks and weekly supervisor walk‑throughs to monthly or quarterly formal audits of hygiene conditions and controls.

Why are Hygiene Inspections Important?

Here are some reasons why hygiene inspections are important:

- Prevent foodborne illness: Early identification of unsanitary conditions blocks pathogen growth at the source, protecting consumers and reducing recall risks.

- Avoid cross-contamination: Structured checks verify that equipment, surfaces, and storage zones stay segregated, preventing harmful transfer between raw and ready-to-eat items.

- Enhanced product quality: Routine assessments confirm consistent temperatures, handling practices, and sanitation cycles that preserve freshness and shelf life.

- Maintain business reputation: Demonstrated hygiene controls signal reliability to customers, auditors, and partners, strengthening trust and market positioning.

- Ensure compliance: Regular inspections validate alignment with food safety standards and industry regulations, reducing exposure to legal or regulatory setbacks.

- Avoid penalties & cost savings: Proactive oversight catches issues before they escalate into fines, product losses, or operational shutdowns, preserving capital.

- Improve operational efficiency: Clear, verified hygiene protocols streamline workflows, reduce rework, and support predictable, high-performing production environments.

Hygiene Audits vs Hygiene Inspections

A hygiene audit is a structured, often independent evaluation of how well an organization’s hygiene system, procedures, and controls meet defined standards, while a hygiene inspection is a point‑in‑time check of conditions on the ground to see if they are clean and safe.

| Dimension | Hygiene Audit | Hygiene Inspection |

| Core purpose | Evaluates whether the hygiene management system works as designed and aligns with defined standards. | Checks real-time hygiene conditions to confirm cleanliness and detect immediate risks. |

| Definition | A structured review of hygiene policies, controls, training evidence, records, and overall program effectiveness. | A point-in-time examination of surfaces, equipment, staff behavior, and environmental conditions. |

| Primary focus | System design, adequacy of controls, quality of documentation, trend data, and overall effectiveness of the hygiene program. | Current state of operations, visible hazards, non-conformities, hygiene lapses, and immediate safety concerns. |

| Scope | Broad and holistic (SOPs, logs, training files, risk assessments, walk-throughs). | Narrower and condition-driven, focused on what is happening now on the floor. |

| Depth | In-depth: investigates root causes and verifies whether controls are effective. | Moderate: identifies issues requiring corrective action but not underlying system design. |

| Frequency | Monthly, quarterly, or annual, depending on certification cycles, customer requirements, and internal governance. | Routine (daily, weekly, or shift-based), supporting ongoing operational control. |

| Who performs it | Internal auditors, corporate specialists, or external certification bodies. | Supervisors, hygiene officers, quality technicians, or regulatory authorities. |

| Output | Formal report with scores, non-conformities, trends, and system-level recommendations. | Action list of issues, corrective actions, and deadlines (sometimes regulatory). |

| Best use | Periodic assessment of the hygiene program, benchmarking between sites, and long-term improvement. | Daily control, quick detection of hygiene failures, maintaining readiness for regulators or customers, and preventing escalation. |

Key Areas Assessed During Hygiene Audits

Key areas assessed during hygiene audits focus on operational discipline, risk control, and the integrity of food-handling practices. Auditors look for measurable behaviors and conditions that directly influence food safety and regulatory compliance. Each area represents a high-impact checkpoint that determines whether a facility can prevent contamination, protect consumers, and sustain consistent food quality.

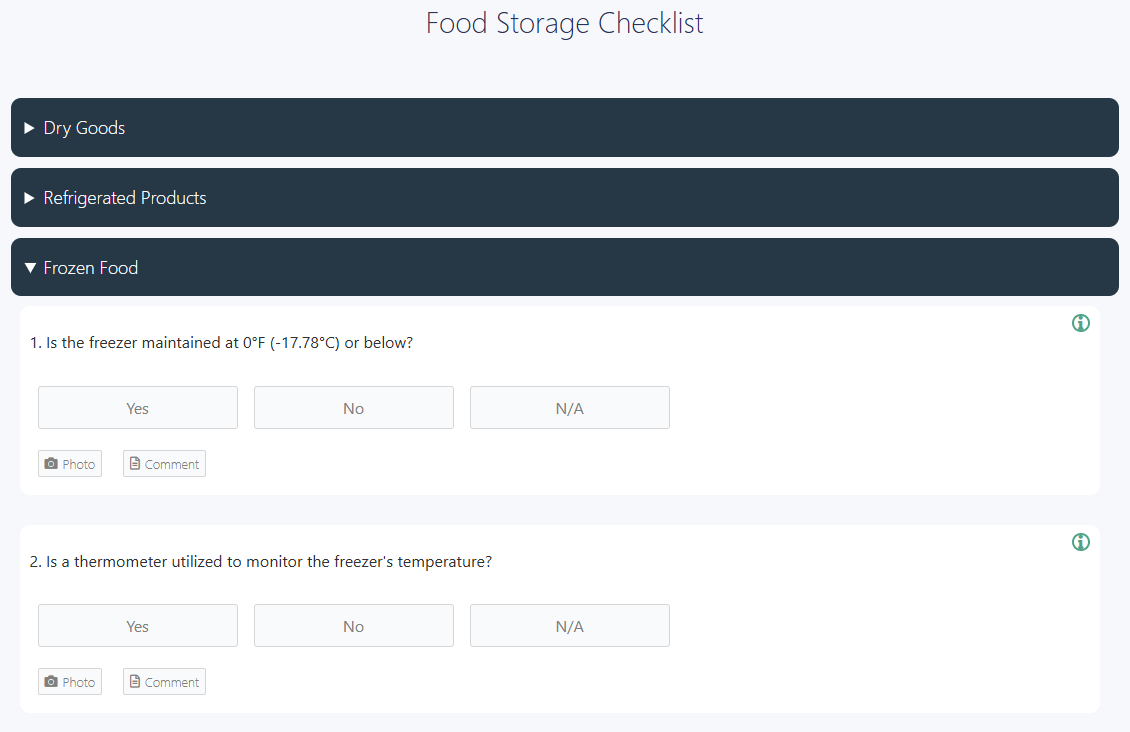

Food Storage and Handling

Proper storage practices protect ingredients from cross-contamination and spoilage. Auditors verify that raw and ready-to-eat foods are separated, labeled, and dated. They check whether containers are sealed, shelving keeps products off the floor, and first-in, first-out rotation is consistently applied. Handling procedures are reviewed for proper use of utensils, avoidance of bare-hand contact, and adherence to allergen-control protocols.

Kitchen Cleanliness

Clean workspaces reduce microbial growth and prevent physical hazards. Hygiene audits examine the condition of preparation surfaces, cutting boards, sinks, appliances, and ventilation systems. Inspectors assess whether cleaning schedules are followed, detergents and sanitizers are used correctly, and high-touch areas are disinfected at required intervals. Evidence of residue, grease buildup, or dirty equipment signals systemic lapses.

👉 Free & Customizable Checklists

GoAudits offers these checklists to perform kitchen inspections and ensure operational efficiency and compliance with hygiene standards.

→ Restaurant Kitchen Cleaning Checklist

→ Kitchen Cleaning Log

→ Kitchen Closing Checklist

→ Kitchen SOP Checklist

→ Kitchen Equipment Maintenance Checklist

→ Home Kitchen Inspection Checklist

→ Kitchen Quality Control Checklist

→ Deep Clean Commercial Kitchen Checklist

Temperature Control

Auditors confirm that refrigerators, freezers, and hot-holding units maintain required temperatures to prevent pathogen growth and that calibrated thermometers are used during cooking, cooling, and reheating. They evaluate logs for accuracy and completeness and observe whether staff take corrective action when temperatures fall outside critical limits.

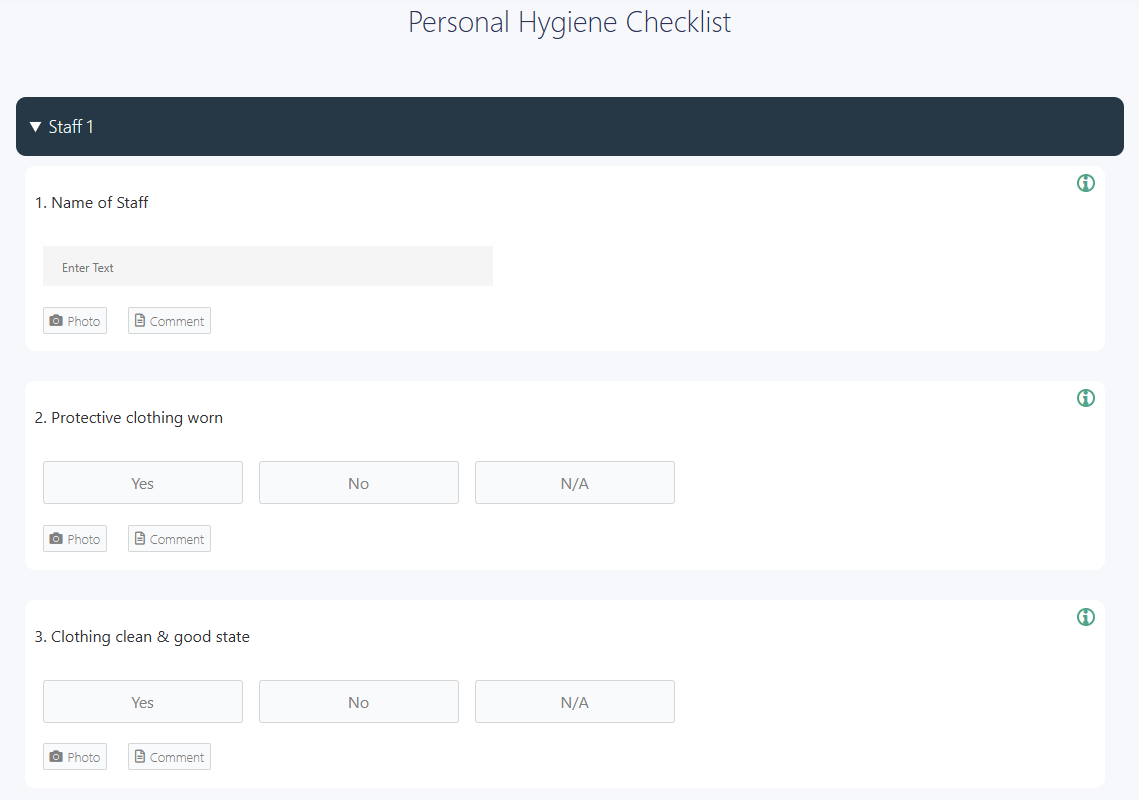

Employee Hygiene

Assessors review handwashing frequency, glove use, uniform cleanliness, and adherence to illness exclusion policies. They observe whether employees follow proper handwashing steps, avoid touching their face or hair, and maintain clean protective clothing. Training records and on-the-job behavior are both evaluated for consistency.

👉 Use this free personal hygiene checklist to perform regular checks and ensure food safety.

Pest Prevention

Auditors inspect storage rooms, drains, doors, and exterior areas for entry points, droppings, nesting materials, or damaged packaging. They confirm that traps and monitoring devices are maintained, that contracted pest-control providers conduct routine service, and that corrective actions are documented promptly.

👉 Free & Customizable Checklists

Use these checklists to enforce strong pest-control measures and safeguard food and equipment.

→ Pest Control Checklist for the Food Industry

→ Pest Control Audit – Bakery

→ Monthly Pest Control Checklist

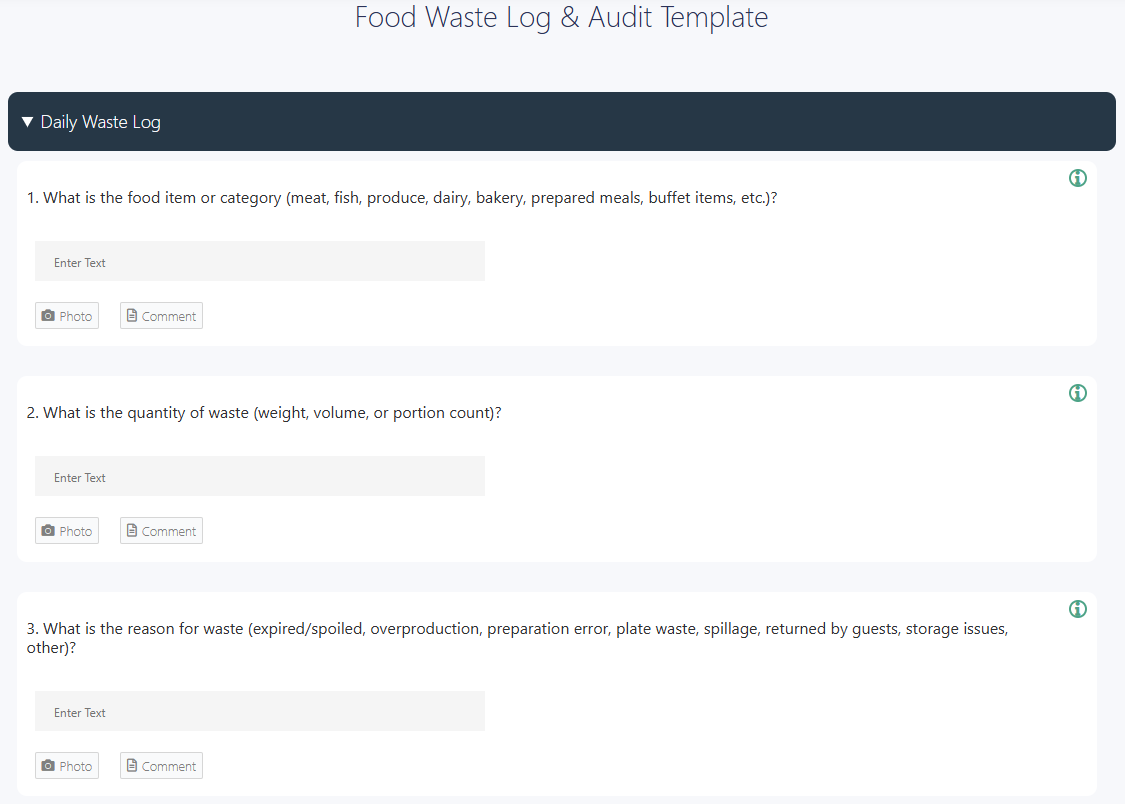

Waste Disposal

Hygiene audits check that bins are covered, emptied frequently, and cleaned as scheduled. They verify proper segregation of food waste, recyclables, and hazardous materials to prevent odors, contamination, and pest activity. Inspectors also evaluate the cleanliness of waste areas and the handling of used oil, chemicals, and other regulated waste streams.

👉 GoAudits offers this free food waste log & template to perform food waste audits and ensure effective waste management.

Steps to Perform Internal Hygiene Checks

Follow these steps below to perform an internal hygiene audit.

1. Define the Scope and Objectives

Start by clarifying what the audit will cover, who will participate, and the outcomes you need. Specify the areas, equipment, and processes under review. Align objectives with regulatory requirements and internal performance standards so the audit produces actionable data rather than general observations.

2. Review Existing Hygiene Procedures

Examine current standard operating procedures to understand baseline expectations. Identify the controls, responsibilities, and monitoring methods already in place. This ensures the audit measures actual performance against documented requirements, not assumptions or outdated practices.

3. Conduct Hygiene Training

Prepare staff through focused training on hygiene protocols, audit expectations, and personal responsibilities. Training should reinforce critical practices such as handwashing, sanitation cycles, waste handling, and cross-contamination prevention. Properly trained teams provide more reliable data and reduce preventable deviations during the audit.

4. Perform On-Site Hygiene Checks

Inspect work areas, equipment, and personnel practices directly. Prioritize high-risk zones, sanitation tools, chemical storage, and process flows. Use checklists to maintain consistency, but allow room for observational judgment. Capture evidence through notes, photos, and measurements to verify compliance or highlight gaps.

5. Document Findings in a Hygiene Audit Report

Consolidate observations into a structured report that clearly separates compliant behaviors from nonconformities. Include root-cause insights, risk ratings, and recommended improvements. A precise report accelerates decision-making and supports traceability during regulatory reviews.

6. Implement Corrective Actions

Assign responsibilities, set timelines, and deploy resources to address each nonconformity. Corrective actions may include revising hygiene SOPs, providing retraining, upgrading equipment, or modifying workflow designs. Track progress to ensure issues are resolved and do not recur.

7. Review and Improve the Audit Process

Evaluate audit effectiveness by assessing whether corrective actions worked, whether new risks emerged, and whether audit methods captured the right data. Use these insights to refine future audit criteria, tools, and training. Continuous improvement strengthens hygiene controls and supports long-term operational reliability.

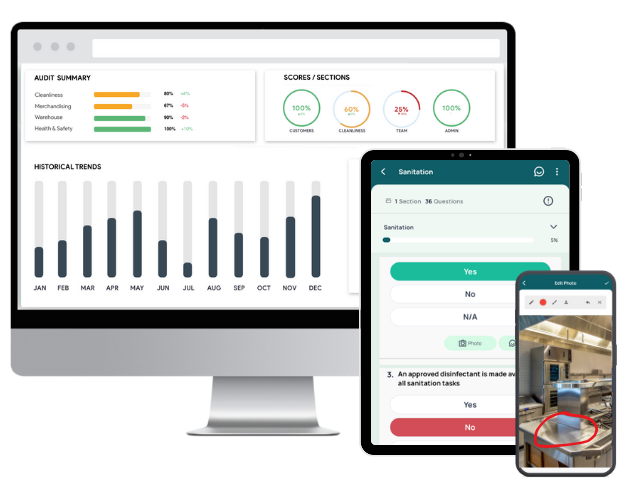

Perform Hygiene Inspections 5X Faster with GoAudits

GoAudits food safety software digitizes every step of the hygiene audit process, from data capture to reporting and follow-up. Capture data on the move, generate instant reports, and act on real-time insights. Ready-to-use checklists, automatic scoring, and integrated corrective actions shorten inspection cycles. With customizable templates, photo evidence, offline capability, and smart dashboards, you can ensure accuracy and accountability and improve standards across every location.

- Access a library of audit templates, build your own forms, or send your existing ones for conversion into digital format.

- Complete audits on any device, online or offline, with photos, annotations, e-signatures, timestamps, and geolocation.

- Generate professional inspection reports automatically, complete with insights, scoring, corrective actions, and distribution workflows.

- Assign tasks during the inspection, track progress centrally, and use automated notifications to keep owners accountable.

- Monitor trends, audit performance, and issue resolution through smart dashboards that provide real-time, location-level data.

Free & Customizable Hygiene Audit Checklists

You can sign up for free and start using these food safety audit checklists, or you can digitize your food SOPs.

- Food Safety & Hygiene Checklist

- Hygiene Standard

- Food Manufacturing Hygiene Audit

- Hygiene Checklist for the Food Industry

- Personal Hygiene Checklist

- Food Hygiene Inspection Checklist

- Food Hygiene Rating Checklist

Common Issues Identified During Hygiene Inspections

Common issues found during hygiene inspections typically trace back to operational gaps that increase safety risks and regulatory exposure. The table below outlines the most frequent findings and their impacts.

| Common Issue | What Inspectors Commonly Identify | What They Do |

| Poor hand hygiene | Missed handwashing steps, empty soap or sanitizer dispensers, improper glove use | Directly increases pathogen transfer to food and surfaces |

| Inadequate cleaning and sanitization | Dirty prep areas, ineffective sanitizers, irregular cleaning schedules | Enables microbial growth and cross-contamination |

| Improper food storage | Unsafe temperatures, uncovered containers, raw food stored above ready-to-eat items | Drives spoilage and raises contamination risk |

| Pest infestations | Droppings, nesting materials, live pests, structural entry points | Signals sanitation failures and creates serious food safety hazards |

| Poor waste management | Overflowing bins, unsealed waste, dirty disposal areas | Attracts pests and contaminates surrounding zones |

| Lack of staff training | Unclear processes, incorrect temperature control, inconsistent cleaning methods | Leads to operational errors and recurring violations |

| Incomplete documentation | Missing temperature logs, cleaning records, pest reports | Weakens traceability and suggests noncompliance |

| Equipment maintenance issues | Broken seals, faulty refrigeration, damaged surfaces, ineffective dishwashers | Prevents proper sanitation and temperature control |

| Cross-contamination risks | Shared utensils, mixed storage, improper surface separation | Increases transfer of allergens and harmful microbes |

| Personal hygiene negligence | Unclean uniforms, jewelry, uncovered hair | Introduces physical and microbial contaminants |

How Hygiene Training Works With Daily Hygiene Inspections

Hygiene training gives employees the skills to handle food safely, follow sanitation procedures, and prevent contamination. It sets the foundation for correct cleaning methods, temperature control, personal hygiene, and other essential practices.

But training is only effective when reinforced on the job. That’s where routine self-inspections come in: they turn hygiene standards into daily habits. Each check serves as a practical reminder of expectations, helping employees apply what they’ve learned while supervisors coach in real time. Gaps in understanding are spotted early, and teams build consistency through repetition, not just periodic refresher sessions.

By integrating training with daily inspections, inspection readiness becomes a natural outcome of everyday operations.

👉 GoAudits: Turning Daily Inspections Into Continuous Hygiene Training

With the GoAudits inspection app, every inspection doubles as a training touchpoint:

– Digital checklists walk employees through your SOPs step-by-step

– Photos & comments allow supervisors to coach in real time

– Automatic reminders prevent skipped hygiene tasks

– Dashboards reveal recurring issues that signal where retraining is needed

This closes the loop between training, practice, inspection, and improvement, helping teams stay consistently compliant across every shift.

FAQs

Start with a clear summary of findings, then document observed conditions, evidence, and scoring against defined standards. Use concise, measurable language, detail both compliant and noncompliant areas, and link each issue to its root cause. Conclude with prioritized corrective actions, responsible parties, and due dates so the report drives accountability and continuous improvement.

It should include high-risk touchpoints, cleaning methods, chemical usage, equipment sanitation, staff hygiene practices, waste handling, storage conditions, and verification steps. Each item should specify acceptance criteria, frequency, and responsible personnel to ensure consistency and traceability during inspections.

Corrective actions typically focus on eliminating root causes through targeted retraining, process redesign, equipment maintenance, and revised sanitation procedures. Organizations document the action plan, assign owners, establish timelines, and verify closure through follow-up audits or performance data to confirm sustained compliance.

Frequency is set by analyzing hazard severity, likelihood of contamination, product exposure, traffic volume, and regulatory requirements. High-risk zones, such as food prep or sterile processing areas, receive daily or per-shift checks, while low-risk support areas follow weekly or monthly schedules to balance safety and operational efficiency.

Address failures by correcting improper cleaning techniques, calibrating or repairing equipment, replacing worn tools, and tightening procedural controls. Reinforce proper hand hygiene, adjust chemical concentrations, improve storage practices, and update training so the underlying issues do not recur in future inspections.