The 6S methodology, also known as 5S + Safety, aims at creating an orderly and efficient workspace, prioritizing everyone’s safety at all times. One crucial aspect of adopting the 6S Lean system is conducting regular and 5S audits to assess process improvements and identify further optimization areas. In this article, we will review the benefits of 6S Lean, and how digital 6S audits can help you effectively implement this methodology on the ground.

What is 6S Lean?

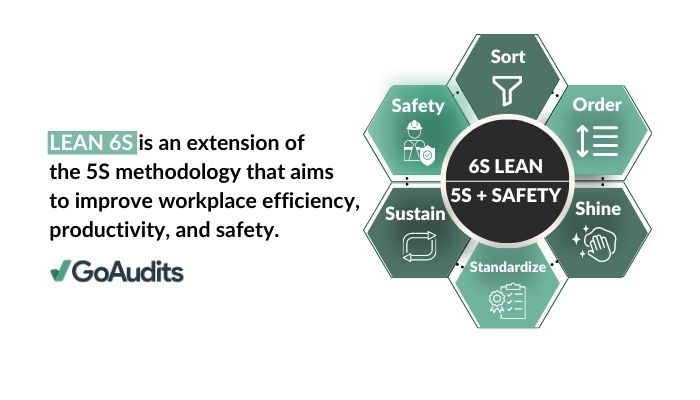

Lean 6S is an extension of the 5S methodology that aims to improve workplace efficiency, productivity, and safety. It is a powerful tool for companies looking to optimize operations and the overall performance of the employees. As the American Society for Quality (ASQ) states “Six Sigma quality” is a term generally used to indicate a process is well controlled”. Built on the proven 5S methodology, 6S goes a step further by prioritizing workplace safety protocols and cleanliness.

6S Lean has already shown tremendous positive impact in manufacturing, healthcare and service industries. Whether you are in one of these industries or not, adopting 6S can help you streamline your operations, reduce waste, and create a safer work environment for everyone. By incorporating safety considerations into every aspect of your operations, you can create a workplace culture that puts your employees first.

The Six Steps That Constitute The 6s Lead System

1. Sort (Seiri)

You can create a more organized and efficient workplace environment by eliminating unnecessary items in your workspace. This frees up valuable space and reduces clutter, allowing your team to focus on important tasks. This crucial step is a game-changer for productivity because it empowers you to identify and prioritize the essential items required for optimal workflow.

2. Set in order (Seiton)

Once you have sorted out the items you need, the next step, in order to streamline your work processes, is to prioritize accessibility and efficiency. One way to achieve this is by strategically organizing your tools, equipment, and materials according to their logical use and frequency of need. By investing time in this step, you’ll not only speed up your workflow but also improve accessibility and reduce the time to complete tasks.

3. Shine (Seiso)

Maintaining a hygienic and inviting work environment should not be overlooked as it greatly benefits employees and leads to an overall improvement in the quality of work. A clean and well-maintained workplace can effectively reduce the likelihood of workplace problems and hazardous situations, and even extend the life of the equipment.

4. Standardize (Seiketsu)

Standardization streamlines processes by identifying best practices and creating policies that support them. It could involve a set of guidelines, visual aids such as signs or posters, and regular site inspections to ensure compliance. As an integral part of the methodology, this step ensures that the recommended practices are followed over time, resulting in better performance and increased efficiency.

5. Sustain (Shitsuke)

The pursuit of sustainability necessitates an ongoing evaluation to ensure that positive changes persist and to facilitate continued improvements. This includes training and educating employees, monitoring progress with regular audits, and enhancing the process continuously.

6. Safety

The ultimate step was created to pinpoint and eradicate any possible hazards that pose a threat to safety in the workplace. This can range from faulty machinery, hazardous materials, to even practices that do not adhere to safety standards. This step not only prevents on-the-job injuries but also fosters an atmosphere of security for all employees.

What Are The Benefits Of The 6S Methodology?

The 6S methodology offers significant benefits to an organization. By promoting safety, identifying potential hazards, and maintaining cleanliness, employees are less likely to experience accidents and injuries. According to the Occupational Safety and Health Administration (OSHA), generally speaking, implementing a safety and health program can reduce injury and illness rates by up to 40%. The 6S method offers a multitude of other benefits that any organization can leverage to improve its productivity and quality of work. These pivotal benefits include:

- greater safety at work

- optimized processes

- enhanced output quality

- improved job satisfaction

- more opportunities for employee development.

By adopting the 6S Lean method and conducting 5S audits, businesses can expect to experience a significant boost in operational efficiency and employee morale, all while delivering exceptional results.

In turn, these benefits can lead to increased profitability, improved customer satisfaction, and a competitive advantage in the marketplace. But at the end of the day, health and safety will always play an important role in a business. An effective 6S program can ensure that all employees are following proper safety protocols and that the workplace is free of potential risks.

How can 6S Audit Software help?

Digital audits are the key to unlocking the potential of the 6S methodology. By harnessing the power of an auditing software, you can track the progress of your 6S Audits and 5S audit implementation in real-time. This allows you to identify areas of improvement and measure the effectiveness of your methodologies. Whether it’s about implementing corrective actions or simply to have an overview of your company’s processes, digital audits are a powerful tool for organizations looking to enhance their workplace excellence.

By using inspection software, you can ensure that your organization stays on track towards achieving and maintaining a clutter-free, organized and efficient workplace. Digital audits offer many advantages, such as:

- Quick adoption & compliance: standardize your procedures and ensure that everyone is aware of the standards, with frequent inspections and digital checklists in everyone’s pocket. Schedule mandatory self-audits and monitor compliance.

- Efficiency: paperless, quicker audits and reports resulting in significant savings in terms of time and resources.

- Analysis: The power of digital audits is in their ability to provide live, accurate insights and aggregated analytics. Pinpoint areas of improvement opportunity and get a reliable way to measure the true effectiveness of the 6S lean methodology.

- Customization: Tailoring digital audits to your organization’s unique needs ensures that pertinent elements are addressed throughout the audit. Such customization assures that everything is noticed during the audit process and enables a more effective and accurate workplace analysis.

- Communication: attach photos, annotations and comments, share reports instantly. Digital audits provide a seamless, paperless way to improve communication and collaboration between different teams and departments, resulting in an optimized performance

How to conduct effective 6S Audits with the GoAudits inspection app

With the GoAudits auditing and inspections app, it’s easier than ever to keep track of 6S compliance and identify areas for improvement. Not only does it simplify the auditing process, but it also offers detailed reports and analytics to help you identify areas for potential risks that could harm your business.

With GoAudits, you can efficiently implement and delegate corrective actions. With just a few taps, you can automatically assign tasks to team members, even outside of your organization. Plus, GoAudits offers you the option to easily share audit results and rapid feedback in real-time that allows you to address any issues and non-conformities promptly.

Schedule audits at your preferred frequency and automatically receive customized reports. The GoAudits audit app will help you streamline your 6S Auditing program and improve compliance. Try GoAudits for free today.

Free 5S Audit and 6S Lean Audit Checklists

- 5S Warehouse Checklist

- Warehouse Health Safety Checklist

- Warehouse Safety Inspection Checklist

- Forklift Safety Checklist

- Manufacturing Safety Inspection Checklist

Find more Audit Checklists in our template library

Wondering if GoAudits is right for you? Check success stories from our customers. With our unrivaled expertise and attentive customer support, we deliver tailored solutions to meet your organization’s compliance goals.