Workers in different industries use tens of thousands of chemicals every day, and although many are suspected of being harmful, only a small fraction are regulated in the workplace. According to OSHA, workers suffer more than 190,000 illnesses and 50,000 deaths annually related to chemical exposures. These numbers reflect a critical need for heightened awareness and effective safety practices. Whether you’re handling cleaning agents or industrial solvents, the risks are real and often underestimated. A strong understanding of chemical safety in the workplace isn’t just a regulatory requirement. It’s essential for protecting health, productivity, and lives on the job.

This article will explore the common examples of chemical hazards in the workplace, and how chemical audits, among other ways, can ensure workplace safety.

- Common Examples of Chemical Hazards in the Workplace

- 10 Steps to Chemical Safety in the Workplace

- Understanding Chemical Audits

- What are Some Common Issues Identified During Chemical Safety Audits

- Types of Chemical Audits

- Key Elements and Steps to Perform Chemical Audits

- Ensure Safety in the Workplace with GoAudits

Common Examples of Chemical Hazards in the Workplace

Chemical hazards pose a risk to health, safety, or the environment due to their composition and potential reactions. Recognizing them prevents exposure and protects workers. Below are common examples of chemical hazards in the workplace you may encounter across industries:

- Acids and Caustic Substances: Strong acids (like sulfuric or hydrochloric acid) and caustics (e.g., sodium hydroxide) rapidly destroy skin and eye tissue on contact. In vapor form, they irritate the respiratory system. Contact can cause burns, inflammation, or permanent scarring.

- Asphyxiants: They include inert gases (e.g., nitrogen, carbon dioxide) that displace oxygen and chemical asphyxiants like carbon monoxide or hydrogen cyanide that block oxygen transport in the blood. Exposure can lead to suffocation or even death with little warning.

- Irritants: Irritants such as chromic acid or nickel chloride damage skin, eyes, and respiratory passages, causing redness, itching, cough, or inflammation. Exposure is typically through skin contact or inhalation.

- Reactive Chemicals: They readily decompose, ignite, or explode when they come in contact with air, water, or other chemicals. Examples include nitric acid, benzoyl peroxide, or silane. Uncontrolled reactions can result in fire, explosion, or toxic gas release.

- Paint: Paints may contain solvents, pigments, and volatile organic compounds (VOCs) like toluene, methyl alcohol, or trace heavy metals like lead or cadmium. VOCs can irritate the lungs, skin, and eyes, and pose long‑term health risks.

- Heavy Metals: Lead, mercury, cadmium, and arsenic are hazardous even in low concentrations. These metals accumulate in the body over time, leading to neurological, kidney, and reproductive damage. Exposure can occur through dust, fumes, or skin absorption.

- Petroleum Products: Products like diesel, kerosene, and lubricants are flammable and toxic. Vapors may cause dizziness or respiratory distress. Skin contact can result in dermatitis or chemical burns, especially with prolonged exposure.

- Glues: Many adhesives contain solvents such as toluene or acetone. Inhalation may lead to headaches, confusion, or long-term neurological effects. Flammability is also a concern, particularly in poorly ventilated areas.

- Pesticides: Even ‘consumer-safe’ pesticides like organophosphates or pyrethroids may cause skin irritation, respiratory problems, or neurological damage. Exposure occurs via air or skin contact.

- Cleaning Products and Detergents: Common in nearly all workplaces, these substances often contain ammonia, chlorine, or surfactants. Misuse or mixing (such as ammonia with bleach) can release toxic gases. Direct contact may cause skin and eye damage.

- Corrosives: Corrosive chemicals destroy tissue upon contact. Examples include nitric acid and potassium hydroxide. Inhalation of vapors can scar respiratory linings.

- Welding Fumes: Fumes from welding contain nitric oxide, carbon monoxide, ozone, metal oxides, and fluorides. These cause respiratory irritation, long-term lung injury, and increase cancer risk.

- Methanol: Methanol is highly toxic if inhaled, ingested, or absorbed through the skin. Symptoms include headaches, dizziness, nausea, and in severe cases, optic nerve damage and blindness.

10 Steps to Chemical Safety in the Workplace

Chemical safety in the workplace demands a structured and proactive approach. Follow these steps to implement a chemical safety program and establish a safer work environment when handling chemicals:

1. Perform Chemical Hazard Risk Assessment

Start by identifying all chemicals present in your workplace. Evaluate the nature of each chemical, its usage, and its potential health or environmental risks. Risk assessments must consider exposure routes, such as inhalation, skin contact, or ingestion, and the frequency and duration of exposure. Prioritize substances based on their severity and the likelihood of harm.

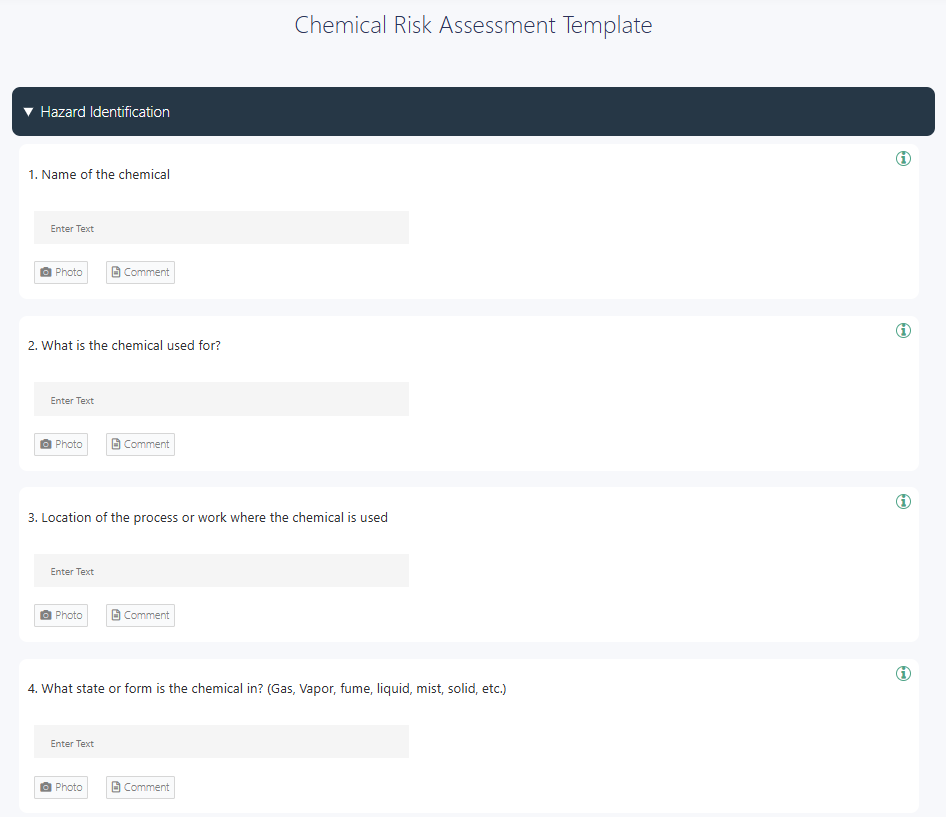

👉 GoAudits risk assessment software offers a free and customizable chemical risk assessment template, which you can use to identify hazards, prevent risk, and ensure chemical safety in the workplace.

2. Obtain and Review Safety Data Sheets (SDS)

Access the latest safety data sheets for every chemical used. SDSs provide crucial information on handling, storage, emergency measures, and first-aid procedures. Ensure all employees can locate and interpret SDSs easily. Regularly review these sheets for updates and align workplace practices with their guidance.

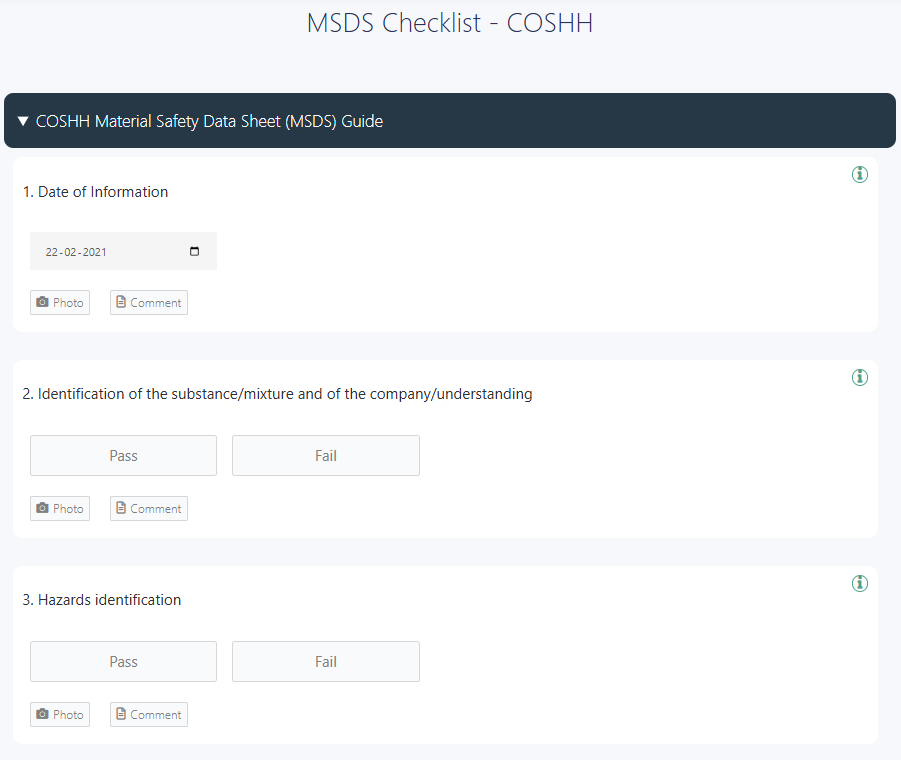

👉 Use this free material SDS checklist to assess hazardous materials, minimize potential risks, and ensure compliance with COSHH safety protocols.

3. Label Chemicals Properly and Store Them Safely

Use clear, standardized labeling in accordance with the Globally Harmonized System (GHS). Labels should include hazard pictograms, signal words, and precautionary statements. Store chemicals in designated areas based on compatibility, flammability, and toxicity. Avoid overcrowding, and use secure containers to prevent leaks or spills.

4. Implement Safe Work Procedures

Develop task-specific procedures that outline step-by-step instructions for using chemicals safely. They should address how to transfer, mix, or dispose of substances, as well as how to decontaminate equipment and surfaces. Ensure all processes comply with legal and industry standards.

5. Provide Proper Ventilation

Install appropriate ventilation systems to control airborne contaminants. Use local exhaust ventilation (LEV) for high-risk areas to capture fumes at the source. General ventilation should support air circulation and minimize the buildup of hazardous vapors. Regularly inspect and maintain these systems for optimal performance.

6. Use Personal Protective Equipment (PPE)

Select PPE based on the specific hazards of each chemical. This includes gloves, goggles, face shields, respirators, and protective clothing. Train workers on correct usage, maintenance, and disposal of PPE. Always ensure equipment is available, accessible, and in good condition.

👉 Free Resources

You can use these PPE checklists to perform PPE inspections, ensuring their availability and proper usage and disposal. You can also digitize your PPE SOPs into actionable checklists with GoAudits.

→ OSHA Personal Protective Equipment (PPE) Checklist

→ PPE Audit Checklist

→ PPE Hazard Assessment Template

→ Donning and Doffing PPE Checklist

→ Arc Flash PPE Suit Inspection Checklist

→ Monthly PPE Inspection Checklist

→ Confined Space PPE Checklist

7. Train Employees Thoroughly

Offer comprehensive training programs that cover chemical hazards, safe handling practices, PPE use, and emergency protocols. Reinforce this training with regular refreshers and practical demonstrations. Encourage a culture of safety by empowering workers to ask questions and report unsafe conditions.

8. Prepare for Emergencies (Including Spill Response)

Establish a well-documented emergency response plan. Include procedures for chemical spills, fires, and exposure incidents. Keep spill kits and emergency equipment readily available and fully stocked. Conduct periodic drills to ensure employees respond effectively and confidently in real-life scenarios.

9. Implement Engineering Controls

Use engineering solutions to eliminate or reduce chemical hazards at the source. Examples include closed systems for transferring chemicals, automated dispensing units, and fume hoods. They are more effective than relying solely on administrative measures or PPE.

10. Perform Chemical Safety Audits and Improve Practices

Conduct routine inspections and chemical audits to assess compliance with chemical safety protocols. Use findings to update risk assessments, refine procedures, and address any gaps. Encourage continuous improvement by incorporating employee feedback and staying informed about regulatory changes.

Understanding Chemical Audits

A chemical safety audit is a systematic, detailed evaluation of an organization’s chemical safety management systems, policies, and procedures. Its primary goal is to identify chemical hazards in the workplace, assess the effectiveness of existing control measures, and ensure compliance with relevant legal and regulatory requirements. This process helps protect worker health, prevent environmental harm, and reduce the risk of chemical incidents.

A chemical safety audit should be conducted by a team with specific expertise in chemical safety, including:

– Safety officers

– Environmental health specialists

– Managers, supervisors, or team leaders with relevant training

– Workplace health and safety (WHS) representatives

They should have a strong understanding of chemical hazards, regulatory requirements, and best practices in chemical management.

How Chemical Audits Ensure Chemical Safety in the Workplace

Chemical audits maintain a safe, compliant, and efficient workplace. Here’s how:

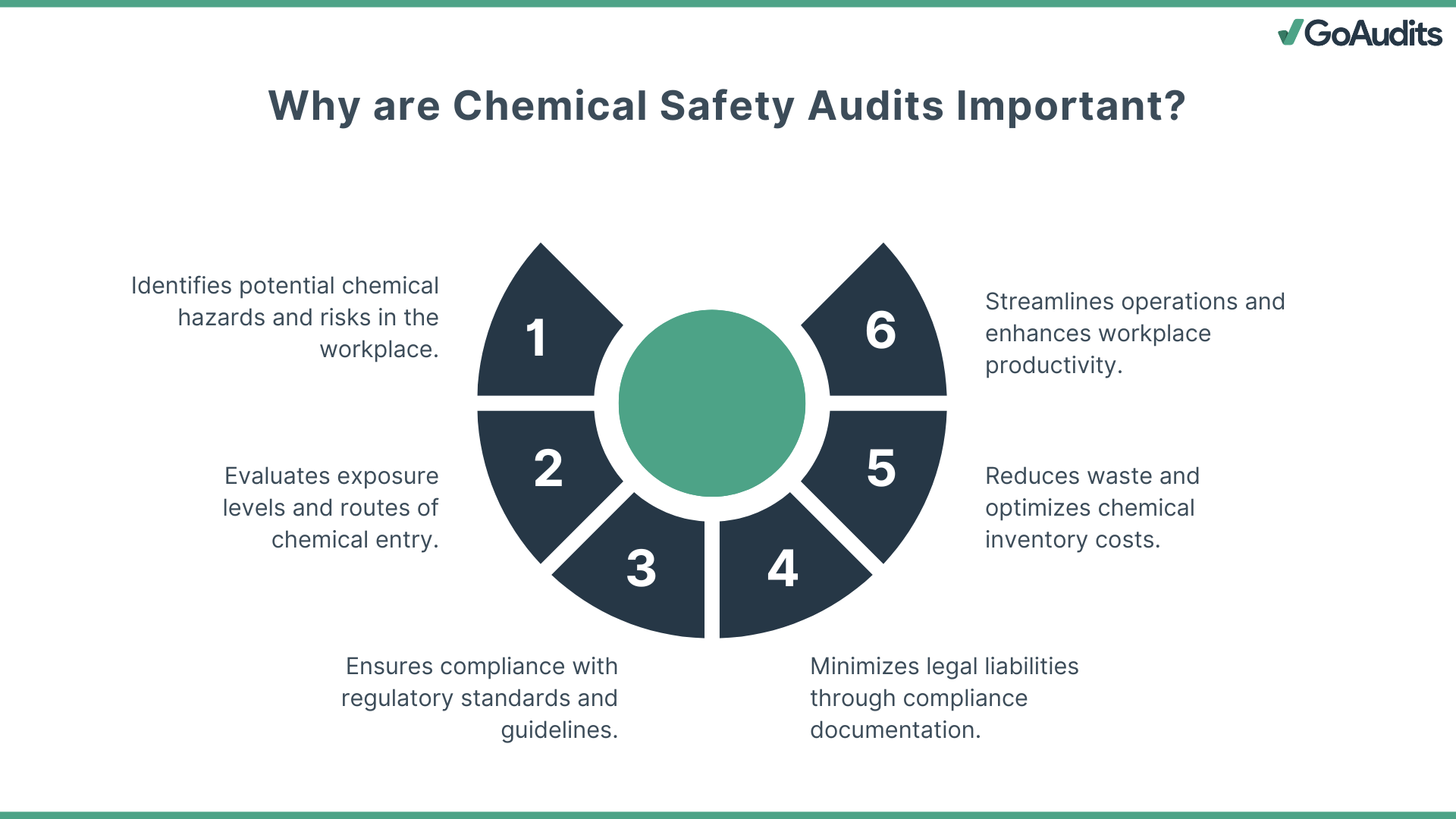

Every substance on-site is reviewed for its chemical properties, potential hazards, and interaction with other materials. Chemical audits help uncover outdated inventory, mislabeling, improper storage, or unsafe handling practices, recognizing risks before they evolve into incidents.

A systematic chemical audit enables you to evaluate exposure levels, assess routes of entry (inhalation, dermal, ingestion), and determine necessary control measures.

Chemical safety audits help you pinpoint unsafe conditions such as leaky containers, faulty ventilation, or expired SDSs, reducing the likelihood of chemical burns, inhalation injuries, or contamination. Regular chemical audits ensure proper labeling, safe storage, and appropriate use of PPE, contributing to a safer working environment.

OSHA’s exposure limits, known as Permissible Exposure Limits (PELs), are a foundational tool for preventing chemical accidents and protecting workers’ health in the workplace. Here’s how they accomplish this:

– Setting legal maximums for chemical exposure

– Requiring exposure monitoring and controls

– Driving safer work practices and training

– Incorporating safety margins and scientific research

– Supporting emergency response and accident prevention

Chemical safety audits identify areas where flammable or reactive substances are improperly stored or used without sufficient controls. It ensures the separation of incompatible chemicals, grounding of containers to prevent static discharge, and maintenance of fire suppression systems, reducing the risk of fire incidents and explosions in the workplace.

Regulatory bodies, such as OSHA, EPA, and local environmental agencies, impose strict guidelines on chemical handling. Chemical audits ensure your practices align with these standards, stay ahead of regulatory expectations, and build a defensible compliance framework. Non-compliance can result in fines or shutdowns.

If an incident occurs, chemical audit records can prove your compliance efforts. This minimizes legal liabilities and helps mitigate financial damages resulting from lawsuits, fines, or compensation claims.

Chemical safety can identify redundant stock, eliminate expired or unused chemicals, and optimize procurement. Better inventory control reduces waste generation and disposal costs. Efficient use of chemicals lowers material expenses while extending the shelf-life of your inventory.

Chemical audits streamline your operations. They help standardize procedures, enhance staff training, and improve communication across departments. When employees know where to find materials and how to use them safely, productivity increases and downtime decreases.

What are Some Common Issues Identified During Chemical Safety Audits

Here are some of the most common issues flagged during chemical safety audits:

- Incompatible Chemicals Stored Together: Storing incompatible substances, like acids and bases, oxidizers, and flammables, poses serious risks, including fires, explosions, or toxic gas releases. Chemical audits often reveal poor segregation across storage zones.

- Expired or Improperly Managed Chemicals: Chemicals, especially peroxide-formers, degrade over time and can become unstable or explosive. Chemical safety audits frequently identify containers lacking opening dates or past expiries. These are signs of weak chemical lifecycle controls.

- Out‑of‑Date Chemical Inventory: An inaccurate inventory leads to untracked chemicals, expired substances, or undiscovered hazards. Auditors commonly find mismanaged records and mislabeled containers. Implementing centralized, digital inventories with real-time updates and periodic reconciliation helps maintain accuracy.

- Improper Labelling and Storage: Lacking full chemical names, GHS pictograms, hazard classes, or receipt and open dates are frequent issues. Poor labeling contributes to misplacement or unsafe handling. Proper storage, using chemical-resistant shelves and secondary containment trays, and not exceeding capacities are often overlooked. Chemical safety assessments highlight these to ensure compliance with GHS and OSHA practices.

- Inadequate PPE: Chemical safety assessments reveal issues such as insufficient PPE supplies, damaged equipment, or lack of correct fit. Even when required items like goggles, gloves, lab coats, or respirators are missing, ineffective usage is often a problem.

- Poor Waste Management: Chemical audits often flag improper disposal routes: dumping chemicals down sinks, mixing wastes, mislabeled or overflowing containers, and missing satellite accumulation areas.

- Lack of Emergency Preparedness: Emergency readiness issues include missing spill kits, eye-wash stations, shower equipment, or outdated emergency numbers. Also, staff may be undertrained for spill response or accident protocols. Chemical audits often expose gaps in emergency response planning and drills, stressing their critical importance.

- Equipment Failure or Poor Maintenance: Critical systems such as fume hoods, explosion‑proof fridges, fire alarms, grounding mechanisms, or ventilation are frequently misaligned or malfunctioning during audits. Regular inspections and preventive maintenance schedules are often neglected.

- Lack of Training and Human Errors: Inefficient training leads to mistakes like misplacement, incorrect labeling, or poor PPE usage. Chemical safety audits reveal insufficient or outdated training, a lack of documented health and safety SOPs and chemical hygiene plans, and an absence of user accountability.

Types of Chemical Audits

Here’s a breakdown of the major types of safety audits relevant to chemical operations:

Chemical Safety Audit

A chemical safety audit evaluates how effectively you manage chemical hazards. It focuses on the safe handling, storage, transportation, and disposal of chemicals. It reviews procedures, safety equipment, hazard communication, and emergency preparedness. You must ensure that proper labeling, containment, and ventilation systems are in place and functioning. A chemical safety audit regularly can mitigate the risk of chemical exposure and ensure a safer work environment.

Chemical Management and System Audit

It involves assessing your entire chemical lifecycle management, from procurement to disposal. It examines your systems for tracking chemical inventories, employee training, and safety data integration. An effective audit ensures you maintain a centralized, controlled approach to chemical handling. It helps you identify inefficiencies and gaps in oversight, reducing the likelihood of unsafe practices and compliance failures.

Compliance Audit

Compliance audits focus on whether your operations align with local, national, and international chemical safety regulations. These audits compare your practices with standards set by regulatory agencies such as OSHA, EPA, REACH, or local environmental boards. A compliance audit in the chemical industry not only keeps you legally compliant but also prevents penalties and reputational damage.

Incident-Triggered Audit

When an accident, near-miss, or safety incident occurs, an incident-triggered audit is initiated. It investigates root causes, system failures, and response adequacy. This audit is essential for understanding what went wrong and how to prevent recurrence. It provides actionable insights to improve your emergency response and update preventive strategies.

Safety Data Sheet (SDS) Audits

An SDS audit verifies that your facility maintains accurate, up-to-date Safety Data Sheets for all hazardous substances. It ensures that employees can access critical chemical safety information at all times. It supports hazard communication and regulatory compliance under GHS guidelines.

Environmental Risk Audits

Environmental risk audits assess your facility’s impact on the surrounding environment due to chemical processes. They identify potential contamination risks, emissions, and waste management issues. These audits are crucial for sustainable operations and maintaining community trust.

Key Elements and Steps to Perform Chemical Audits

Here’s a breakdown of the key elements and essential steps to perform a chemical hazard risk assessment effectively:

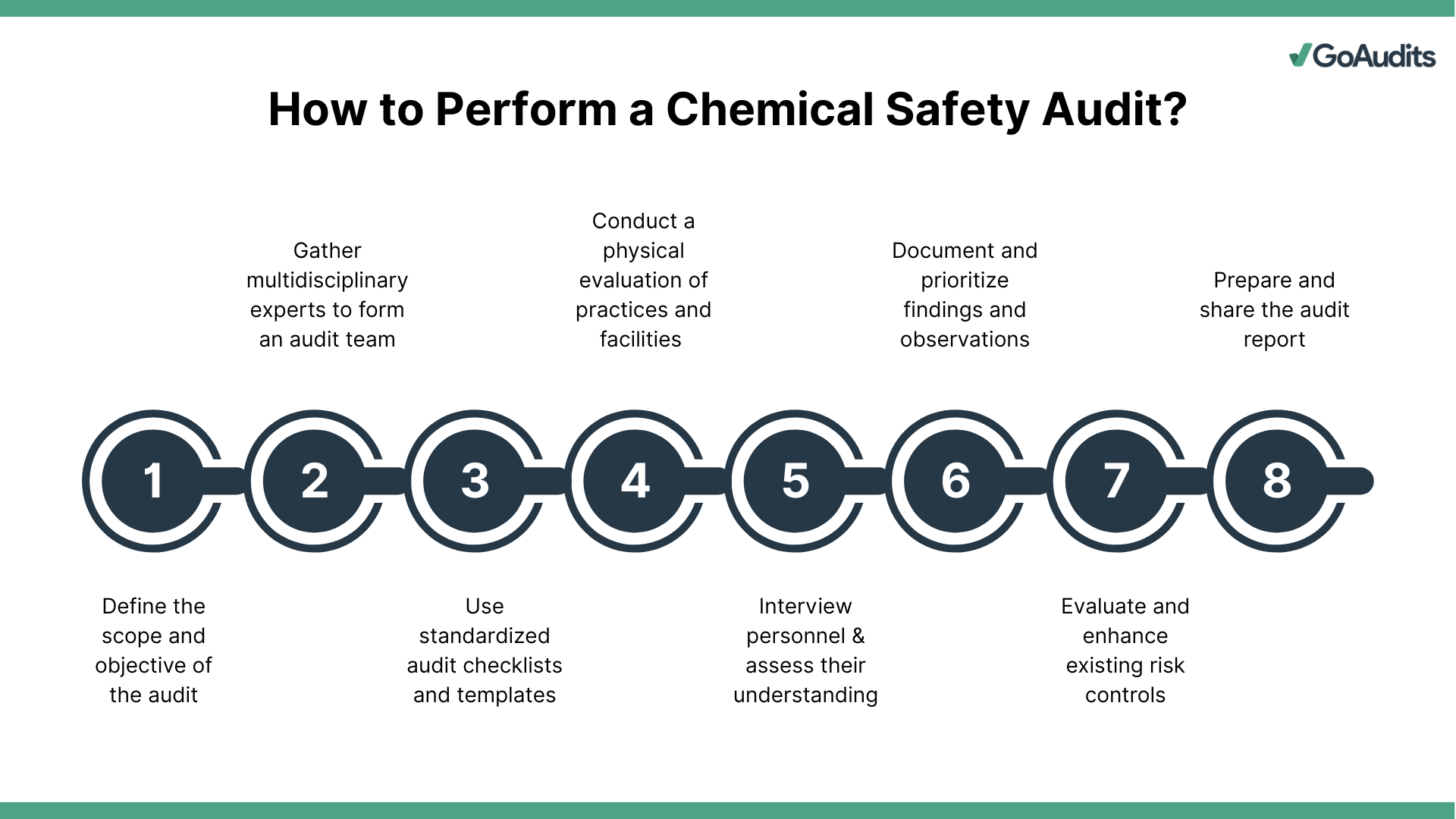

1. Define Scope and Objective

Begin by clarifying what will be audited and why. Determine whether the focus is overall chemical safety, compliance with regulations, waste management, or emergency preparedness. Set measurable objectives to guide the audit process.

2. Assemble the Audit Team

Gather a multidisciplinary team with expertise in safety, operations, environmental compliance, chemistry, and emergency planning. Include at least one audit lead to coordinate, ensure consistency, and maintain documentation. Pre-audit coordination aligns the team on objectives, roles, and responsibilities

3. Use Audit Checklists and Templates

Leverage standardized checklists tailored to your scope. Your toolkit should include sections for inventory, storage, labeling, waste management, PPE, administrative controls, and emergency procedures. Templates from credible sources help ensure consistency and completeness.

👉 Free Resources

GoAudits offers the following checklists to simplify the process of chemical safety assessments and audits. You can sign up for free and start using these checklists.

→ Chemical Safety Checklist – COSHH

→ Chemical Handling Checklist

→ Chemical Risk Assessment Template

→ MSDS Checklist – COSHH

→ HSE COSHH Assessment Template

→ Hazardous Material Inspection Checklist

→ OSHA Flammable and Combustible Materials Checklist

4. Conduct Physical Chemical Safety Assessment

Perform a detailed physical inspection of the facility. Focus on these key areas:

- Chemical inventory

- Handling and storage

- Labeling

- Waste management and disposal

- PPE and administrative controls

- Emergency preparedness

5. Interview Personnel

Talk with frontline staff to assess understanding of procedures, safety protocols, and emergency response. Ask about access to SDSs, comfort in stopping unsafe operations, and effectiveness of hazard communication. Involve both employees and their representatives where applicable.

6. Document Observations and Evaluate Findings

Record all findings, including compliant practices, deficiencies, photos, dates, and locations. Use standardized templates to log non-conformances with clear descriptions and suggested corrective actions.

Analyze each observation based on severity, frequency, and risk to personnel or environment. Use a scoring system or ranking method to prioritize issues needing swift remediation

8. Assess Risk Control

For each deficiency, evaluate the effectiveness of the existing control. Recommend enhancements if controls fail to sufficiently mitigate risks. Consider using a risk matrix to guide remediation urgency.

9. Prepare Audit Report

Compile a professional, structured report:

- Executive summary

- Detailed findings

- Recommendations and corrective actions

- Positive observations

- Photos, checklists, interview summaries, etc.

Keep the language precise and actionable. Offer guidance on implementing improvements and suggest timelines for follow-up or re-audit. Share the report with relevant departments to initiate timely corrective measures.

Ensure Safety in the Workplace with GoAudits

Ensuring workplace safety demands accuracy, consistency, and speed. GoAudits safety inspection software is an all-in-one solution designed to streamline safety inspections, chemical audits, and compliance processes. Replacing paper-based audits with a mobile-first platform, GoAudits helps you focus on preventing incidents and enforcing standards, without the administrative burden. You can proactively manage inspections, assign corrective actions, and leverage data for smarter decisions. Whether you’re a safety manager or compliance officer, GoAudits enables seamless inspection workflows tailored to your organization’s structure and goals.

- Choose from a library of ready-made health & safety audit checklists, build your own using a simple drag-and-drop interface, or let us do it for you at no additional cost.

- Perform chemical audits using mobile devices, even when you’re offline. Attach and annotate photos, and add e-signatures, geo-location, and time stamps for full accountability.

- Instantly generate comprehensive reports at the end of each audit, populated with photos, timestamps, user details, and assigned actions. Customize audit reports and share them with relevant stakeholders.

- Tag issues during audits and assign corrective actions with deadlines and responsible parties. Track task ownership, priority levels, and resolution status from a central dashboard.

- Automate report distribution, approvals, and reminders. Define rules to escalate unresolved tasks or overdue items. Configure organizational structures to control access, reporting lines, and approval chains.

- Get a holistic view of audit scores and performance, issue frequency, and resolution rates. Identify recurring safety issues and patterns to drive strategic decisions.

- Monitor all planned audits, corrective actions, and overdue tasks from a centralized platform.