Key Takeaways

- Regular 5S audits can help you improve efficiency, safety, and quality and reduce costs.

- Traditional audits rely on paper checklists and manual data collection. This leads to time-consuming audits that lack objectivity and consistency and offer limited visibility into trends.

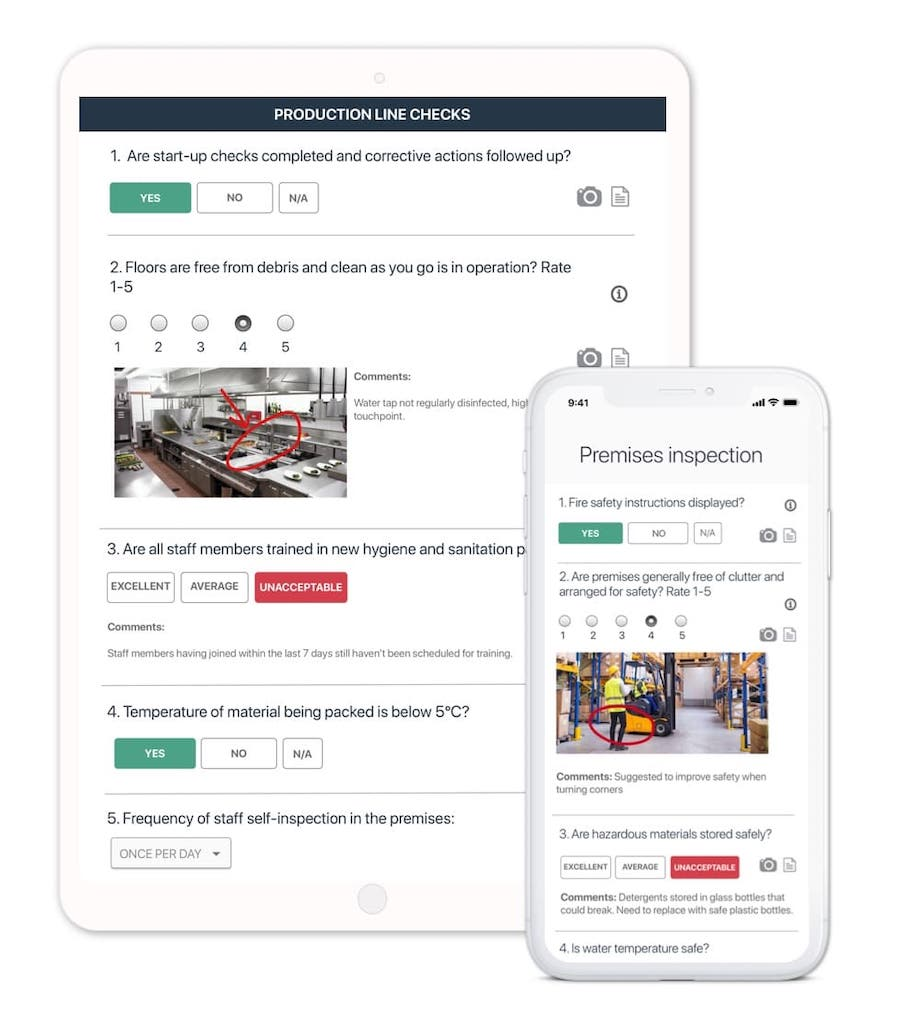

- 5S audit apps streamline 5S checks through features like digital checklists, standardized reporting, and inspection dashboards.

While the 5S Principles provide the foundation for a clean, organized, and efficient work environment, 5S audits ensure your team consistently adheres to them.

Read on to learn about 5S audits, their purpose, benefits, and how to conduct them effectively. Furthermore, discover why companies are switching to digital 5S software to streamline 5S checks.

How to Optimize 5S Checks With 5S Audit Software?

By using a 5S inspection app, you can track the progress of your 5S implementation in real-time. This allows you to identify improvement areas and measure your plan’s effectiveness.

Whether it’s about implementing corrective actions or simply having an overview of processes, digital audits are a powerful tool for organizations looking to enhance their workplace excellence. 5S software ensures that your organization stays on track toward achieving and maintaining a clutter-free, organized, and efficient workplace.

Digital audits offer many advantages, such as:

- Quick Adoption & Compliance: Standardize your procedures and ensure everyone is aware of the standards with frequent inspections and digital checklists. Schedule mandatory self-audits and monitor 5S compliance.

- Efficiency: Paperless, quicker audits and reports result in significant savings in terms of time and resources.

- Real-Time Analysis: The power of digital audits is accurate insights and aggregated analytics. Pinpoint areas of improvement and get a reliable way to measure the true effectiveness of your 5S program.

- Customization: Customize checklists to your organization’s unique needs, and quickly tweak audit questions based on the learnings and corrective actions. Create a continuous, positive loop of improvement in your workplace.

- Communication: Attach photos, annotations, and comments, and share reports instantly. Digital audits provide a seamless, paperless way to improve communication and collaboration between different teams and departments, resulting in optimized performance.

5S Audits: What Are They in Lean Manufacturing?

5S audit is the process of verifying the implementation of the 5S Lean Principles. It involves inspections conducted by auditors to check how well the workforce and the processes adhere to the 5S methodologies.

The auditors typically look for how well the workspace is organized, if all the labelings are correct, if the team is following the cleaning protocols, and if workers follow the established manufacturing SOPs. The ultimate goal of a 5S audit is to maintain an efficient, organized, and safe working environment.

Benefits of 5S Checks

5S audits help maintain and sustain standards. They provide a feedback loop that supports a culture of continuous improvement. 5S audits enable organizations to:

- Maintain Standards: 5S inspections provide a structured approach to continuously measure the effectiveness of the 5S Principles, preventing teams from reverting to suboptimal ways of working.

- Identify Areas of Improvement: With an effective 5S audit plan, you can identify issues in the 5S implementation and other challenges hampering productivity, and then create an action plan to overcome them.

- Improve Maintenance Practices: They highlight equipment that needs maintenance, leading to improved preventive maintenance practices and potentially reducing downtime.

- Make Data-Driven Decisions: 5S checks equip teams with rich data about the effectiveness of the implemented actions, used to make strategic and operational decisions.

- Engage Employees: You can foster a culture of responsibility and accountability amongst workers, encouraging them to actively participate in maintaining manufacturing standards.

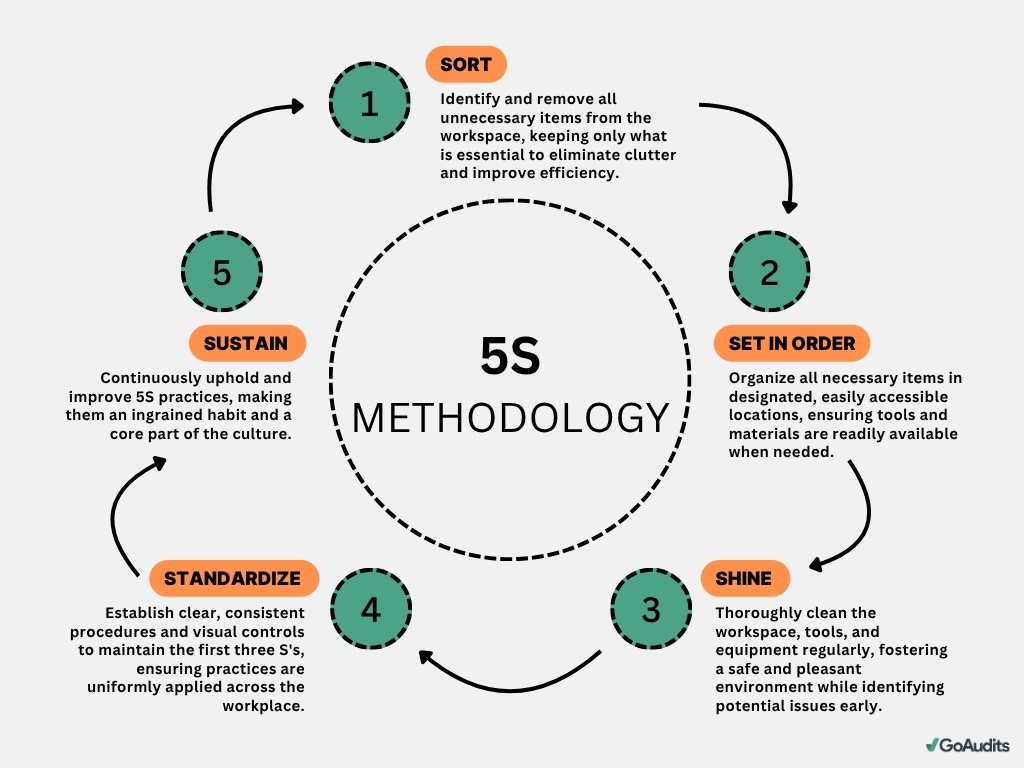

What Does Each ‘S’ in 5S Stand For?

Each ‘S’ in 5S represents a key principle:

1. Sort (Seiri)

This involves identifying and removing unnecessary items from the workspace. The goal is to declutter and keep only what is essential for current operations, reducing distractions and maximizing space.

2. Set in Order (Seiton)

Once clutter is removed, this step focuses on organizing the remaining essential items efficiently. Everything should have a designated place that is easily accessible and clearly labeled, minimizing wasted time searching for tools or materials.

3. Shine (Seiso)

This principle emphasizes regular cleaning and inspection of the workspace, tools, and equipment. A clean environment not only improves safety and morale but also helps identify potential issues like equipment malfunctions or leaks early on.

4. Standardize (Seiketsu)

This involves establishing clear procedures, guidelines, and visual controls to maintain the first three S’s. Standardization ensures consistency in practices across the workplace and helps prevent a return to cluttered or disorganized conditions.

5. Sustain (Shitsuke)

The final ‘S’ is about maintaining the discipline to continuously apply and improve the 5S principles. It’s about making 5S a habit and an integral part of the daily work culture through ongoing training, audits, and commitment from everyone.

5S Audit Procedure: How to Conduct a 5S Audit?

A 5S audit procedure follows a systematic approach to ensure a comprehensive assessment of adherence to 5S standards and continuous improvement.

1. Establish Audit Standards and Checklists

Start by establishing audit standards against which the auditors would evaluate the workplace. You may want to define criteria for each stage of the 5S steps. Based on these criteria, create checklists. Outline each item in detail, and attach photos of the ideal state wherever necessary. To measure the outcome numerically, implement a scoring system for questions.

Conducting manufacturing audits on paper and spreadsheets is inefficient, as they are difficult to handle and don’t assist in studying trends.

Therefore, companies are switching to 5S audit checklist software to create their own checklists (or use the existing templates). Auditors can access these digital checklists through mobile phones and perform inspections even in locations with low internet connectivity.

Here are free 5S audit checklists to help you get started:

2. Communicating and Training Auditors

Ensure the auditors are well-versed with 5S methodologies, audits, and checklists. Communicate audit criteria to the inspectors as clearly as possible. They should know how they are expected to apply them and what they are supposed to do in case of non-compliance.

Train auditors in using checklists and how to communicate results to other stakeholders. Introduce audit best practices like adding notes and taking photos of the non-conformances.

3. Scheduling Audits

Consistent and systematic 5S assessments help in creating a culture of accountability. Also, regular audits allow managers to identify when adjustments to the 5S system might be necessary.

Start by determining the frequency of audits – daily, weekly, monthly, quarterly, annually, or a combination thereof – depending on operational needs and the area of audits. Implement a rotational schedule to cover all areas.

Determine and allocate the time required to audit each area. Ensure auditors are notified of the upcoming audits and equipped with the correct checklists and tools. Your 5S inspection software should be flexible, allowing adjustments/reassignments to accommodate changing priorities and unforeseen circumstances.

4. Conducting the 5S Assessment Audit

Conduct the audit using the established checklists and 5S standards for each step. Ensure you inspect all areas, tools, processes, labels, cleaning SOPs, etc. Audit each area based on 5S categories:

- Sort: Check that items or tools not required in the process are removed.

- Set in Order: Verify all materials, tools, and information are easily accessible to workers. Run the 30-second test, which assesses how long a worker takes to find a particular tool. If it’s less than 30 seconds, it is considered a pass.

- Shine: Check if the workplace is spotless, without dirt, leaks, contaminants, foreign materials, etc.

- Standardize: Check how well processes and operations adhere to the defined guidelines and standards.

- Sustain: Verify the implementation of previously suggested corrective measures and assess their impact.

With digital audit tools, you can add comments/notes for further actions, take photos of non-conformances, and assign corrective actions.

5. Compiling Findings

Compile all your findings into a comprehensive report. It should include observations, scores, photos, additional notes, suggested measures, and notable successes. Review the report with other stakeholders to further analyze the findings, gain new insights, and lay out action plans.

With digital inspection tools, you can generate and share reports with the team in just one click. This quick sharing allows faster analysis of the findings and issue resolutions.

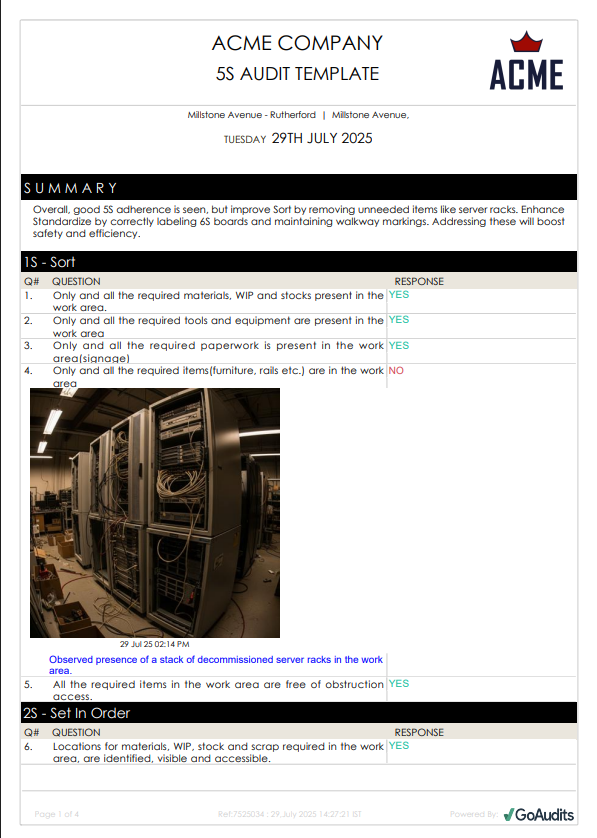

Free 5S Report Sample Format

Here’s an example of a checklist-based 5S audit report sample generated with GoAudits:

These reports also mention automatically calculated 5S audit scores that help businesses quantify and track quality over time.

Scoring a 5S audit involves assigning point values (often 0-3) to each element of 5S. The final score is the average of points scored in each component of the 5S methodology. For example, if a workplace scores 2,1,3,2,1 in each “S,” the total 5S audit score would be 1.8.

With the ability to immediately email the report to the relevant parties, we get real-time information that allows our supervisors to sign off corrective actions and resolve any issues much quicker than before.

Eddie Odie, Quality Control Manager, Nissin Foods USA

Full Case Study: How Nissin Foods leverages GoAudits to streamline quality control inspections and audits.

6. Analyzing Results

Study the outcomes to identify the areas of improvement. Prioritize issues based on urgency and suggest corrective actions after discussing them with your team. Use a digital 5S inspection software to access the earlier audit data. Study trends and pinpoint recurring issues. The software assigns scores to all audits, allowing you to monitor performance across departments, categories, and locations.

Inspection Dashboard: Learn how it helps you study historical trends and identify areas for improvement.

7. Rolling Out Action Plans

Implement the improvement measures highlighted in the previous step. Assign tasks to team members (or contractors), set deadlines, and track their progress.

Conduct follow-up audits to assess the effectiveness of the implemented changes and how well they are sustained. Use the results obtained in the follow-up audits to make further optimizations and continuous improvements.

Implement Audit Plans With the GoAudits 5S Audit App

With the GoAudits inspection app, it’s easier than ever to keep track of 5S compliance and identify areas for improvement. Besides simplifying the auditing process, with GoAudits, you can:

- Schedule audits at your preferred frequency

- Create instant reports with 1 click, customized to your brand

- Delegate corrective actions to individuals in your team or outside your organization

- Use Analytics Dashboards to identify areas for improvement and potential risks

- Address any issues and non-conformities promptly

- Streamline your 5S audit program and improve compliance

With a rating of 4.8 stars on Capterra, GoAudits is trusted by some of the biggest names in the manufacturing industry.

» Customer Success Story: How businesses leverage GoAudits to save time and improve operations.

FAQs About 5S Audits

A 5S inspection can be performed at any point to assess the current state of a workplace. You can perform a 5S inspection after implementing the 5S system in a particular area or even revisit an established system to identify areas that may have relapsed.

No, PDCA is not exactly Kaizen. However, it provides a structural framework for Kaizen’s philosophy of making small, incremental improvements. Furthermore, the “Check” and “Act” stages of the PDCA cycle emphasize data collection and analysis, important pillars of Kaizen.

The frequency of 5S audits in lean manufacturing depends on the project and the size of your workplace. Weekly or monthly audits work for smaller work areas or projects, while larger workplaces might benefit from quarterly or biannual audits.

Besides these scheduled audits, you can conduct surprise audits to assess the implementation of 5S Standards.

A 5S checklist is a list of items that auditors need to check during 5S audits. It ensures that all aspects of the 5S principles are checked.

A 5S audit checklist typically includes questions for each “S,” guiding the auditor to assess items like unnecessary tools, designated storage locations, cleaning and maintenance procedures, etc.

Scoring a 5S audit plan involves assigning point values (often 0-3) to each element of 5S. The final 5S audit score is the average of points scored in each “S”. For example, if a workplace scores 2,1,3,2,1 in each “S,” then the total 5S audit score would be 1.8 ((2+1+3+2+1)/5).

Inspection apps like GoAudits enable manufacturers to efficiently implement many other audit programs and Lean manufacturing tools, without extra administrative and paperwork burdens for their teams:

1. 6S Audits: These audits add “Safety” to the original 5S Principles and ensure a clean, organized, and safe work environment.

2. Layered Process Audits: They focus on observing and validating how products are made, allowing engineers to identify problems and pinpoint their root causes.

3. Gemba Walks: They involve visiting the shop floor to observe, question, learn, and suggest improvement measures to achieve the business goals.

4. PDCA: It is a cyclical Lean Management process that supports continuous improvement through testing hypotheses, assessing their results, and implementing the ones that worked.