All-in-one Preventive Maintenance Program Software

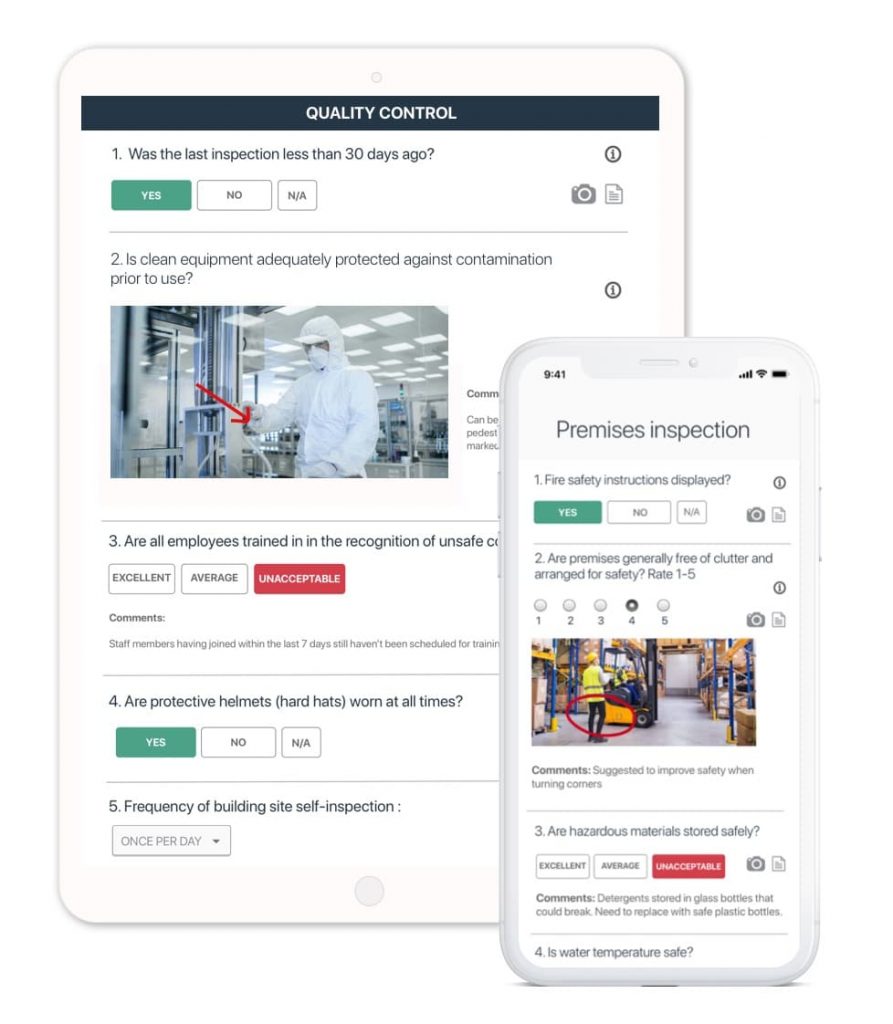

Easy-to-use mobile app

- No more paper forms or reports

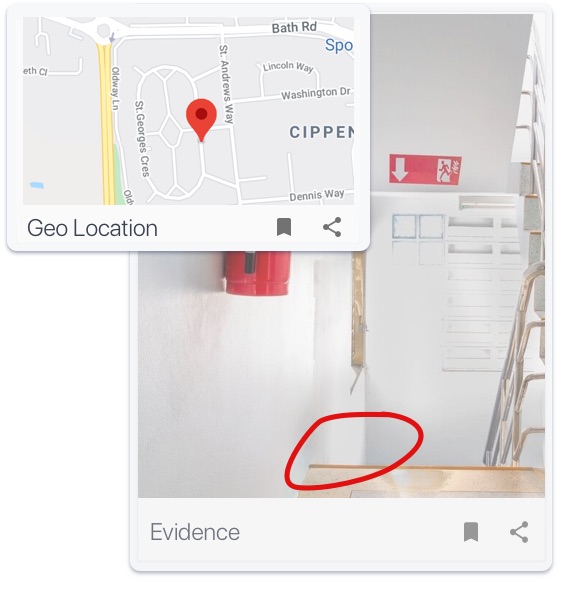

- Document everything in the field with photos, annotations, comments

- Fully functional offline, on all phones, tablets and computers

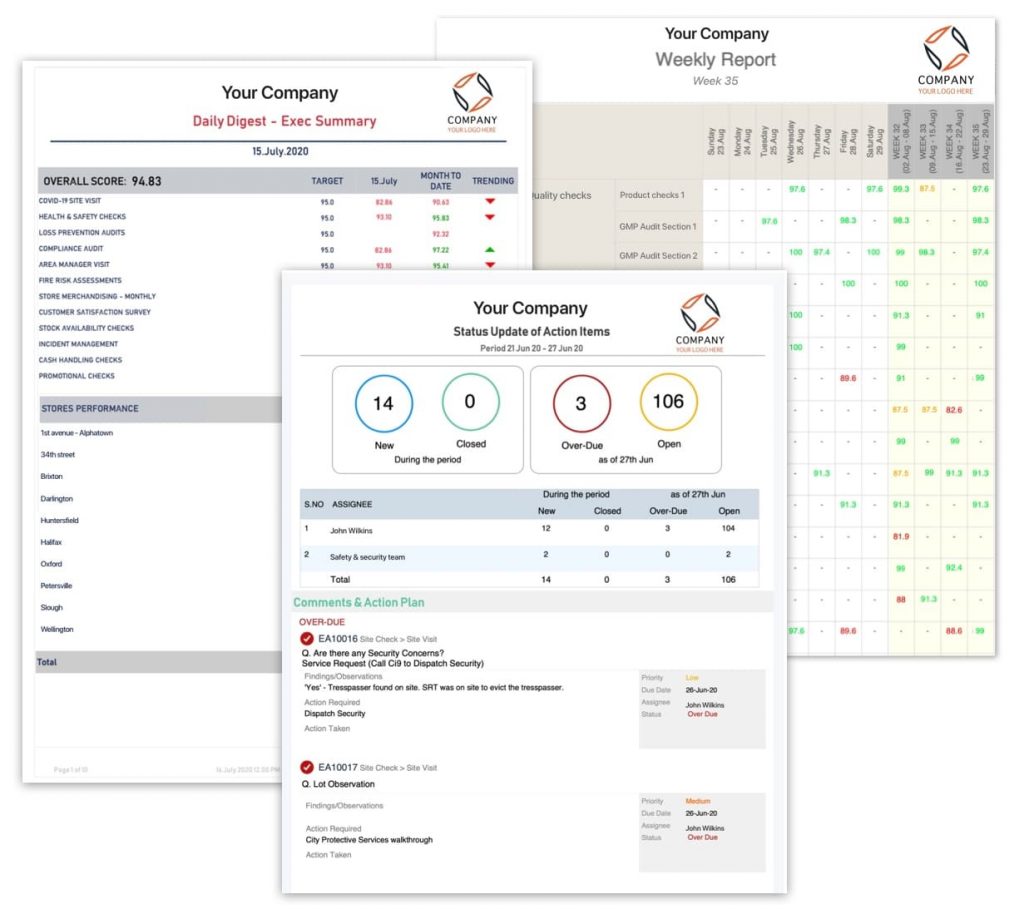

Instant reports & analytics

- Schedule maintenance inspections in advance

- Automatically generate and email professional-looking reports

- Identify recurring issues

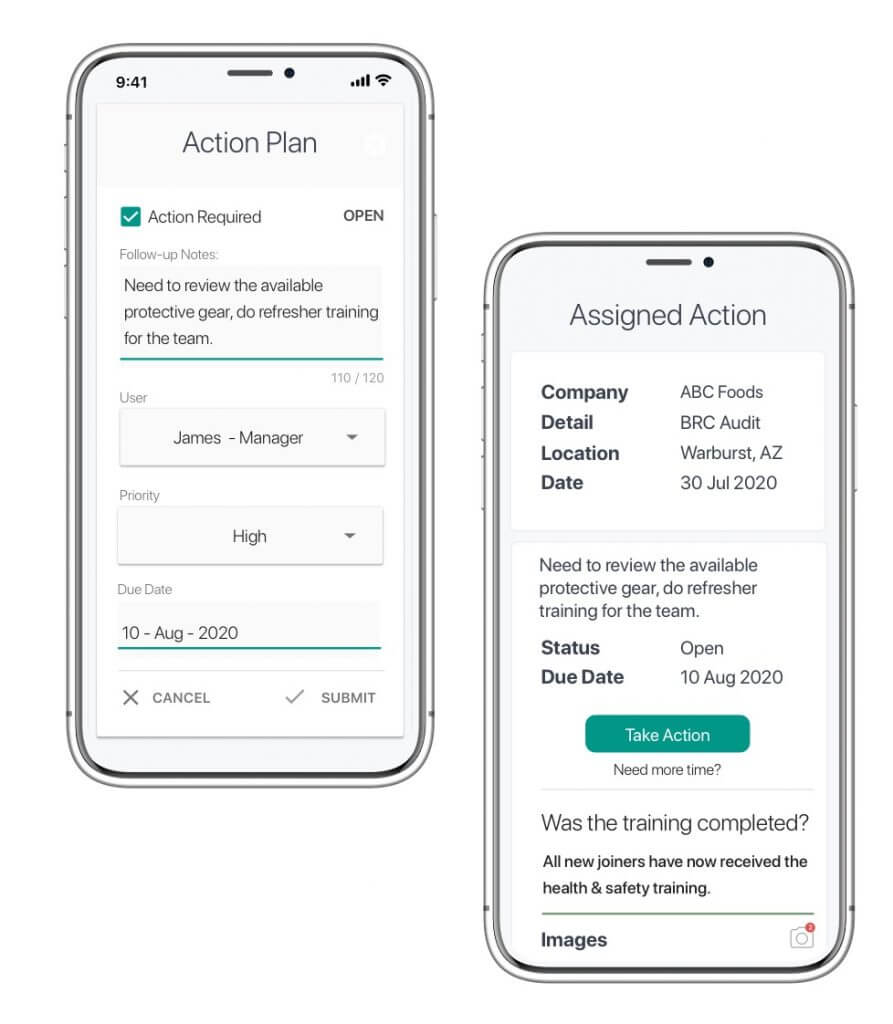

Task management

- Log issues right away and assign follow-up tasks

- Track resolution on an interactive dashboard

- Simplify communication between teams

Prevent Breakdowns before they Occur

Establish a regular maintenance plan for your vehicles, equipment, technology and other assets to prevent expensive failures and unexpected downtime.

Shift your maintenance strategy from reactive to preventive.

Paperless & efficient maintenance inspections

No more paper forms, Excel checklists or emails. Standardize, schedule and efficiently manage preventive maintenance inspections.

- Create preventive maintenance checklists

- Schedule and assign maintenance inspections

- Send notifications of upcoming tasks

- Ensure consistence no matter the team or location

- Monitor performance with real-time reports and dashboards

Implement and Track Corrective Actions

Better communication, coordination, and decision-making, leading to improved asset performance and reduced maintenance costs.

- Assign corrective actions to internal or external users

- Track non-conformance resolution in real-time

- Get updates from your suppliers and keep evidence of actions taken

★★★★★ 5/5

“97% Audit Responsiveness”

Our auditing time drastically reduced, we increased audit frequency. Audit responsiveness went from 65% to 97%. The mobile app is so easy to use, and the live reporting of the non-compliant items allows seamless follow-up. A fantastic product!

★★★★★ 5/5

“96% completion on GMP audits”

Our audit completion rated improved tremendously. With instantly compiled and emailed reports, we get real-time data that allows our supervisors to sign off corrective actions and resolve issues much quicker.

★★★★★ 5/5

"Simple intuitive platform”

GoAudits is our primary platform for both retail food safety audits at our 70+ cafes as well as for our supplier audits.

Pros: 1) Simple, intuitive audit platform 2) Helpful, friendly support team 3) Very affordable 4) Nice reporting functionality and dashboard.

Pros: 1) Simple, intuitive audit platform 2) Helpful, friendly support team 3) Very affordable 4) Nice reporting functionality and dashboard.

Brian C.Senior Food Safety Manager

Real-time insights on PM scheduling, equipment and assets

Gather real-time data on equipment, including performance, usage patterns, and maintenance history. Make informed decisions to improve your standards, as well as reduce costs and risks.

Keep a documented record of all maintenance activity to ensure compliance and avoid costly penalties or accidents.

100s of maintenance inspection templates

Use the checklist templates featured on the GoAudits app and adapt them to your needs. Or simply send us your existing checklist and we will fully configure it for you.

What is Preventive Maintenance (PM) Software?

Preventive maintenance software (or PM maintenance software) is a computer program for businesses to schedule and manage maintenance tasks for their assets and equipment.

Key features of this software include inspection and maintenance scheduling, asset tracking, reporting, and workflow management.

Maintenance scheduling software with an efficient corrective action tracking feature can help managers prevent unnecessary downtime and repairs.

Who Needs Preventive Maintenance Program Software?

Various professionals employ preventive maintenance software for their equipment and assets. Here are some common examples:

- Maintenance and Facility Managers: They use it to schedule and assign preventive maintenance tasks to technicians, and it helps them monitor work orders and asset health.

- Operations Managers: They utilize the software to minimize downtime and disruptions. They get real-time data and reports on maintenance activities, allowing managers to optimize and streamline operations for increased efficiency and productivity.

- Asset Managers: They leverage the software to track the location, condition, and history of assets to identify potential problems, preventing costly repairs and ensuring asset longevity.

Key Industries that Use Preventive Maintenance Software

Manufacturing industries use it to schedule regular maintenance for critical machinery, production lines, and other equipment. This helps to prevent costly downtime and ensure that products meet quality standards.

Transportation companies use maintenance PM software to maintain their fleets of vehicles, aircraft, and ships, ensuring the safety and reliability of their transportation systems.

Construction companies use it to maintain their construction equipment. This helps to prevent delays and ensure that projects are completed on time and budget.

Oil and gas companies use preventive maintenance scheduling software to maintain oil rigs, platforms, pipelines, and refineries. This helps to ensure their facilities’ safe and efficient operation and prevent environmental hazards.

Besides these, facility management, healthcare, utilities, and government employ software to manage their maintenance inspection tasks.

What Does a PM Maintenance Software Do?

Industrial tools, right from ladders to specialized devices, require maintenance. With preventive maintenance program software, managers can schedule inspections and regular maintenance in advance.

Maintenance software also allows you to report defects and take measures to fix them instantly. This enables prompt implementation of corrective actions, strengthening the safety and efficiency of the operations.

Maintenance solutions also equip managers with actionable insights, allowing them to monitor asset maintenance in real-time. Thus, with preventive maintenance tracking software, you can decrease downtime and improve equipment’s life expectancy.

What Makes Preventive Maintenance Software Popular?

Preventive maintenance management software is popular because of its ability to transform how businesses approach equipment care. Firstly, it fosters a proactive approach, prioritizing prevention over reactive repairs. This minimizes downtime and extends equipment life, leading to significant cost reductions in the long run.

Secondly, the preventive maintenance solutions streamline workflows. This frees up valuable time for the maintenance team by automating tasks like scheduling, reporting, data analyzing, and recordkeeping. Additionally, improved communication and collaboration features boost team efficiency.

Finally, preventive maintenance software programs offer enhanced visibility and control. They provide a centralized platform for managing assets, gathering real-time data, and ensuring regulatory compliance. This level of control empowers businesses to make data-driven decisions and optimize their maintenance programs for maximum effectiveness

Why Should You Use Preventive Maintenance Software?

A preventive maintenance program backed by powerful software can transform how you execute inspection and maintenance tasks. Let’s take the example of GoAudits to illustrate how industrial preventive maintenance software can be a total game changer:

- Fully Customizable: With simple preventive maintenance software like GoAudits, you can build customizable inspection checklists from scratch. You can categorize these checklists based on location, equipment, department, etc. You can define the actionable for each attribute, like recording, monitoring, etc.

- Data-Backed Reporting: During an inspection, the auditor can take photos of the defects, add comments, assign corrective actions, and more. Once the inspection is complete, the inspector can generate and share the report instantly. It contains photos, comments, and evidence. Apart from the new inspection findings, the audit report mentions the historical data.

- Scheduling Audits: Preventive inspection and maintenance software like GoAudits are more than just inspection tools. They allow you to set an audit and maintenance calendar in advance. You can include the inspector’s name, audit date, equipment, priority level, etc., in the audit schedule.

- Assigning and Monitoring Corrective Actions: The inspectors can assign corrective actions during inspection. Assignees receive the ticket for the task in their inbox and can send the update themselves. Maintenance managers can track, set reminders, reassign, postpone, or cancel the corrective action from the inspection dashboard.

- Real-time Insights: Through the advanced analytics dashboard, you can analyze inspection and maintenance performance for your unit. You can assess the downtime of equipment, your team’s performance, the responsiveness of the assignees, recurring issues, etc. Real-time insights help you update your maintenance strategy for effective operations.

How to Select an Industrial Preventive Maintenance Software?

Selecting the right preventive maintenance schedule software becomes crucial with various options available. Here are the key factors you must consider before zeroing down on good equipment preventive maintenance software:

- Assess Your Needs and Budget: Identify your specific maintenance requirements, team size, and available budget to set realistic expectations.

- Define Your Software Features: Prioritize the functionalities most crucial for your needs, like work order management, photos, digital signature, reporting, or mobile access.

- Integration Features: Choose software that integrates with your existing preventive maintenance program for streamlined data flow and efficient workflows.

- Online Reviews: Read customer testimonials on credible review sites, like Capterra, to understand real users’ experiences.

- Customer Support and Training: Learn about the support and training resources available for a smooth implementation and integration.

- Request Free Demos and Trials: The best preventive maintenance software, like GoAudits, offers free demos and trials for users to try the software and ask questions.

GoAudits enables you to schedule inspections, manage tasks, track equipment health, and gain valuable insights to optimize maintenance programs, all within a centralized platform. Our preventive maintenance application allows technicians to access work orders, capture data, and complete tasks efficiently, even offline.

GoAudits promotes proactive maintenance, minimizing downtime and extending equipment lifespan. It encourages managers to make data-driven decisions for improved operational efficiency and cost reduction.

Seeing is Believing

Get a live demo customized to your unique needs, or get started with a 14-day FREE trial.

- No credit card, no commitment.