Food Safety Audit Checklists & Report Sample

Template Library > Food & Hospitality Checklists > Food Safety Checklist

Conduct Faster Inspections with Food Safety Checklist Templates

This food safety inspection checklist is designed for evaluating hygiene and safety standards in food production establishments. It includes checks covering policy arrangements, delivery, storage, sanitization, food preparation, cooking, temperature monitoring, food service, personal hygiene, pest control, waste management, and more. With GoAudits, you can conduct up to 5x faster audits.

- Conduct food safety, hygiene, and quality inspections with ease, even without internet access

- Automatically generate detailed reports right after inspections

- Assign and track follow-up tasks instantly, ensuring prompt attention to issues

- Instantly generate ready-to-be-shared reports at the end of each inspection

- Assign corrective actions and involve the right people at the right time

- Get a complete overview of audit scores across locations, teams, or topics.

With the GoAudits Food Safety Software, you can:

- Eliminate paperwork: conduct efficient digital audits

- Customise this template or easily create your own

- Save time with instant reports & assign corrective actions

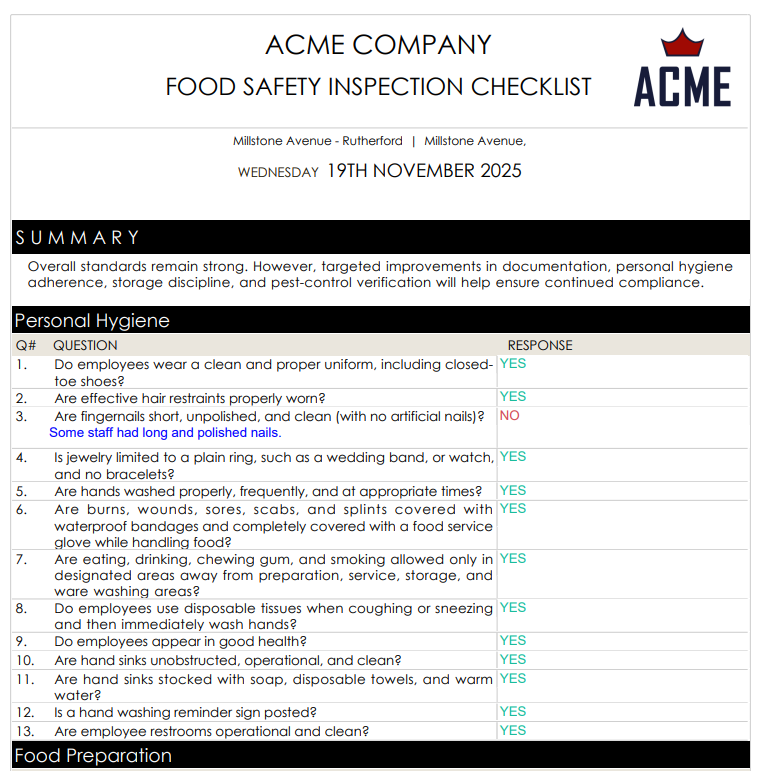

Personal Hygiene

Food Preparation

Hot Holding

Cold Holding

Refrigerator, Freezer, And Milk Cooler

Food Storage And Dry Storage

Cleaning And Sanitizing

Utensils And Equipment

Large Equipment

POLICY ARRANGEMENTS

Delivery

Storage

Ambient Storage

Sanitisation

Initial Food Preparation

Cooking & Reheating

Cold Storage

Hot Food

Temperature Monitoring Procedures

Food Service

Loose Fittings

Wood, Packing Materials, Cloths, WireWool Etc.,

Complaints Procedure

Personal Hygiene Standards

Bad Habits

Clothing

Hair

Hand Washing

Maintenance

Pest Control

Food Sampling & Retention

Food Hygiene Training

Food Safety Policy Training

Cleaning Schedule, Etc

Cleaning Standards

Vending Machines

Refrigeration & Maintenance Records

Waste Management

Sanitary Provision

What are Food Safety Checklists?

Food safety checklists are digital tools used to ensure food is safely handled, prepared, stored, and served within establishments like restaurants, food manufacturing facilities, and other food service environments. These checklists cover key areas necessary to prevent foodborne illnesses, uphold food safety standards and regulatory compliance, and ensure customer satisfaction. These include personal hygiene, proper food storage and preparation, sanitation of facilities and equipment, temperature controls, pest control, and waste management.

There are various types of food safety checklists, including the following:

- Kitchen health and safety checklist

- FSMA compliance checklist

- Food safety due diligence checklist

- Food safety checklist for restaurants

- Food truck health inspection checklist

- Warehouse food safety checklist, etc.

Each checklist is designed to suit specific food business needs, ensuring regular safety tasks are completed and infrequent ones, such as deep cleaning or pest inspections, are not overlooked.

Why are Food Safety Audit Checklist Templates Important?

The benefits of using food safety audit checklists are manifold, including the following:

- Ensure compliance with industry regulations and food safety standards (e.g., FDA, GFSI).

- Maintain consistent food quality through systematic monitoring and corrective actions.

- Prevent foodborne illnesses by identifying and addressing hygiene and handling risks.

- Streamline and simplify the audit process with a structured evaluation framework.

- Improve operational efficiency and reduce costs by minimizing food waste and preventing non-compliance penalties.

- Provide clear documentation and verifiable evidence of compliance for audits and certifications.

What are the Key Components of Food Safety Audit Checklists?

Here are the key components of any food safety inspection checklist.

- Personal Hygiene: Essential for preventing foodborne illnesses. A food safety checklist inspection form should ensure that all food handlers practice good hygiene. These include regular hand washing, wearing clean uniforms, and avoiding direct contact with food when ill.

- Food Handling and Preparation: Focuses on reducing the risk of contamination during food handling and preparation. A food hygiene checklist should cover areas such as washing hands and surfaces often, separating raw and cooked foods to prevent cross-contamination, and avoiding the use of food beyond its expiry date.

- Cleaning and Sanitation: Essential for eliminating foodborne pathogens. Regular cleaning and sanitizing of all food contact surfaces, equipment, and utensils are required, along with proper waste disposal to maintain a clean and sanitary kitchen environment.

- Procurement of Raw Materials: A food hygiene inspection checklist covers areas ensuring the quality and safety of all ingredients used. This includes selecting fresh and wholesome foods, choosing foods processed for safety (e.g., pasteurized milk), and ensuring that water and ice are from safe sources.

- Cooking and Serving: Ensures that food is cooked and served safely. Key practices include cooking food thoroughly, especially meat, poultry, eggs, and seafood, and keeping food at safe temperatures until served.

- Temperature Control: Crucial for slowing down or stopping the growth of harmful microorganisms. Food should not be left at room temperature for more than 2 hours, and cooked and perishable foods should be refrigerated promptly.

- Storage: Involves keeping food under conditions that will help maintain its safety and quality. A food hygiene daily checklist should cover areas, including the food is stored at the correct temperature and storage areas are regularly checked for signs of pests or contamination.

- Pest Control: Regular inspections and effective pest control measures are necessary to prevent infestation and ensure a clean, pest-free environment.

- Waste Storage and Disposal: Proper waste management practices are critical to avoid attracting pests and reducing the risk of contamination. A food safety checklist template involves proper waste segregation, ensuring it is stored correctly, and disposed of regularly and safely.

Learn more: How digital checklists help implement Food SOPs

What is a Food Safety Audit Report?

A food safety audit report is a detailed document that evaluates how well a food business complies with established food safety standards and regulatory requirements. It highlights the findings of a food safety audit, including observed practices, non-conformities, corrective actions, and overall compliance status.

It is typically prepared by certified food safety auditors or third-party inspection agencies who assess food handling, storage, processing, hygiene, and documentation systems within the organization.

A food audit report is essential for maintaining audit readiness and ensuring compliance. It helps identify potential risks, verify the effectiveness of your food safety management system, and demonstrate regulatory adherence. Addressing gaps before external inspections can prevent violations, strengthen your organization’s commitment to food safety excellence, and enhance consumer trust.

Key Components of a Food Safety Audit Report Template

Here are the key components of a food audit report:

- Audit Overview: Define the audit’s purpose, outline its scope across processes and facilities, and describe the methodology used for inspection, sampling, and evaluation to ensure transparency and consistency.

- Detailed Findings: Present precise observations supported by verifiable evidence, specify compliance status for each criterion, identify non-conformities, and classify their severity to prioritize corrective measures.

- Corrective Actions: Provide clear recommendations addressing each non-conformity, including actionable plans with responsible parties, establish agreed completion dates, and define follow-up procedures to verify implementation and effectiveness.

- Key Areas of Evaluation: Assess hygiene practices, food storage and handling procedures, sanitation standards, pest control measures, and staff training programs to ensure full adherence to food safety regulations and best practices.

Steps to Prepare a Food Audit Report

Follow the steps below to create a food audit report:

Review the Food Safety Standard and Regulation Requirements

Begin by reviewing all relevant food safety standards and regulatory requirements. Understand the specific obligations under national laws, local authority guidelines, and international frameworks such as HACCP, FSSC 22000, IFS, BRCGS, SQF, etc. This helps define audit objectives and ensures the evaluation criteria reflect the latest compliance expectations.

Use Food Safety Checklists to Perform Audits

Leverage digital checklists to streamline the audit process. Digital food safety checklists enable consistency, minimize manual errors, and allow real-time data collection. Customize these checklists based on operational areas. Using standardized templates also ensures that every audit covers all critical control points systematically.

Record Observations and Classify Them

During the audit, record both compliance and non-compliance findings with supporting evidence. Clearly classify non conformities as minor, major, or critical based on their impact on food safety. It helps prioritize issues and ensures that corrective actions target high-risk areas first.

Recommend Corrective Actions

After identifying non-conformities, recommend specific and achievable corrective actions, and include preventive measures to avoid recurrence. Each recommendation should be clear and actionable to address the root cause of the issue, define timelines for implementation, and strengthen the effectiveness of the food safety management system.

Prepare, Review, and Share the Report

Compile all findings into a structured report. Ensure the report is factual, concise, and supported by evidence. Share the report promptly for timely action, facilitating internal review meetings and driving continuous improvement across food safety operations. However, make sure to review it for accuracy and consistency before sharing.

👉 GoAudits generates audit reports immediately after an audit is finished. You receive a fully formatted report within seconds, already including your notes, photos, timestamps, geolocation data, and assigned actions. You can avoid manual compilation, reduce the risk of errors, and gain a clear, structured summary that is ready to share immediately. This gives you more time to act on findings, maintain accountability across teams, and make faster, better-informed decisions.

Food Safety Audit Checklist PDF Free Download

Food Hygiene Inspection Checklist

This food inspection checklist is designed for the systematic evaluation and assurance of compliance with hygiene standards in food-related processes and facilities. It covers areas such as waste disposal, toilets, training and certificates, records and documentation, personal hygiene, receiving, food storage, cold storage, food preparation, hot/cold holding, delivery, and refreshment areas.

FSSC (Food Safety System Certification) 22000 is a globally recognized certification scheme that ensures the safety and quality of food products throughout the supply chain. Use our free checklists for internal audits, to establish compliance in preparation of the certification audit.

A HACCP checklist is a tool used to ensure that a HACCP plan is being implemented effectively. It provides a systematic way to identify, monitor, and control potential food safety hazards throughout the food production process.

BRC audit checklists provide a standardized framework for evaluating your food safety management system against the requirements of the BRC Global Standard for Food Safety. They cover a wide range of critical components, each designed to evaluate specific aspects of your food safety management system.

The Safe Quality Food (SQF) Program provides a stringent and globally recognized certification that assures consumers and suppliers alike of a product’s excellence in safety and quality standards. You can start your SQF self-assessments immediately with our free checklists.

Food Manufacturing Hygiene Audit

This food safety audit checklist helps you review food safety and hygiene practices in food production establishments. It covers pest control, cleanliness, staff hygiene, waste management, and more. You can use this checklist to identify areas for improvement and ensure compliance with food safety regulations.

This food hygiene rating checklist helps you ensure compliance with UK food safety standards for a higher hygiene rating. It covers areas such as food safety and hygiene procedures, structural requirements, and confidence in management procedures, covering aspects such as staff hygiene, hand washing, food storage, allergen management, equipment cleanliness, pest control, and waste management.

Pest Control Checklist for Food Industry

The food safety checklist template for pest control is designed for the food industry to systematically inspect and manage pest-related risks. It includes food debris sweeping, sealed storage for food products, sealing gaps and holes, maintaining clean yards and areas, using approved chemicals, regular checks for pest activity, repairing fly screens, and maintaining a clean environment to prevent pest infestation.

The food inspection checklist for personal hygiene helps you ensure that staff handling food adhere to proper personal hygiene practices. It covers aspects such as wearing protective clothing, maintaining the cleanliness of clothing and shoes, ensuring nails are short and clean, avoiding jewelry and uncovered skin wounds, confirming staff health, and avoiding bad body odor or strong perfumes.

Food Safety Self-Inspection Checklist

This food safety checklist is designed for self-inspections, covering a broad range of topics to ensure food safety. It includes cleanliness of storage areas, pest control measures, food safety management systems like HACCP, staff training in food safety procedures, cooking and storage temperature guidelines, hand washing practices, storage of raw and ready-to-eat food separately, staff hygiene practices, sickness recording, prevention of cross-contamination, etc.

Food Safety Kitchen Inspection Checklist

This kitchen health and safety checklist helps US businesses systematically review food safety practices and facilities to ensure hygiene standards in kitchens. It covers a wide range of topics such as notice and documentation, food safety, employee health, water and plumbing, equipment and utensils, hand washing facilities, floors, walls, ceilings, toilet facilities, lighting and ventilation, pest control, toxic materials, and garbage handling.

Food Safety Audit Report: Common Mistakes & Tips to Avoid Them

Inadequate Documentation

When records are incomplete or disorganized, it becomes difficult to verify findings or demonstrate compliance. You should ensure that every observation, corrective action, and verification detail is properly recorded and traceable. Supporting evidence such as photographs, test results, or process records strengthens the credibility of your report and minimizes ambiguity.

Lack of Objectivity

Allowing assumptions or personal opinions to influence the report can lead to biased conclusions. You should base every observation strictly on evidence and measurable data. Maintaining neutrality ensures the report reflects actual conditions rather than interpretations. This not only enhances transparency but also builds trust among stakeholders.

Ignoring Root Cause Analysis

Ignoring root cause analysis weakens the corrective action process. Simply noting a nonconformance without identifying its source often results in recurring issues. You should investigate underlying causes instead of addressing only surface-level symptoms. A thorough root cause analysis allows you to propose corrective actions that prevent future deviations.

Overlooking Follow-Up Actions and Audits

Overlooking follow-up actions and audits also undermines the value of the report. An audit is not complete until corrective measures have been verified and their effectiveness confirmed. You should document follow-up timelines, responsibilities, and evaluation criteria. Conducting periodic reviews ensures that improvements are maintained and compliance standards are upheld consistently.

Other Popular Food & Hospitality Templates:

Food Safety Software App

- Easily perform audits anywhere in the facility using a mobile device.

- Capture and attach photos as proof of compliance or areas needing attention.

- Assign tasks, set deadlines, and track progress, all within a single app

- Analyze data from audits to identify trends, pinpoint recurring issues, and assess compliance levels.