Maintaining a safe and hygienic kitchen is essential for protecting customers and meeting regulatory standards. A kitchen inspection ensures every part of your food preparation area, from storage and equipment to hygiene and waste management, meets strict safety and cleanliness requirements. Whether you manage a restaurant, catering service, or home-based food business, kitchen inspections create a compliant, efficient, and risk-free environment. It helps detect potential hazards early, prevent contamination, uphold consistent food safety practices, and promote long-term success.

In this article, we will explore different types of kitchen audits, steps to perform them, common kitchen hazards, free checklists, and more.

- What is a Kitchen Inspection?

- Types of Kitchen Audits

- How to Perform Internal Kitchen Audits?

- How GoAudits Simplifies Kitchen Inspections

- Free & Customizable Kitchen Inspection Checklists

- Common Kitchen Hazards List & Issues Found During Kitchen Inspections

- Kitchen Hygiene Standards: What Inspectors Look For

What is a Kitchen Inspection?

A kitchen inspection is a systematic evaluation of a food preparation area to ensure it meets all hygiene, safety, and operational standards. It involves assessing food storage, equipment sanitation, pest control measures, employee hygiene, and compliance with food safety standards. The goal is to identify risks that could lead to contamination, illness, or operational inefficiencies.

Why are Kitchen Inspections Important?

Kitchen inspections are essential for maintaining food safety, protecting consumer health, and upholding a business’s reputation. Regular inspections help detect potential hazards early, prevent foodborne illnesses, and ensure compliance with regulatory standards. They also encourage consistent sanitation practices, reducing the likelihood of costly penalties, closures, or brand damage.

Who Performs Kitchen Inspections

Kitchen inspections are carried out by both internal and external parties. Internal inspections are conducted by in-house quality or safety managers who monitor daily compliance with food safety protocols. External inspections are performed by local or national health authorities, such as public health departments or food safety agencies, to verify adherence to legal and regulatory requirements. Together, these inspections create a robust system that safeguards public health and ensures consistent food quality.

Key Areas Covered in Kitchen Inspections

Here are some key areas inspected during kitchen inspections:

- Food Storage and Handling: Inspect how food is stored, labeled, and separated to prevent cross-contamination and ensure compliance with temperature control standards.

- Staff Hygiene Practices: Evaluate personal hygiene, use of protective clothing, and adherence to handwashing protocols to maintain food safety.

- Equipment Conditions: Examine the cleanliness, maintenance, and functionality of cooking and refrigeration equipment to verify they meet safety requirements.

- Work Surfaces and Utensils: Check that all preparation areas, tools, and utensils are sanitized regularly and made of non-toxic, easy-to-clean materials.

- Waste Disposal: Review waste segregation, storage, and removal processes to confirm they prevent odor, infestation, and contamination risks.

- Ventilation: Assess the effectiveness of exhaust systems and air circulation to reduce heat, smoke, and airborne contaminants in the kitchen.

- Pest Control: Inspect preventive measures, monitoring systems, and documentation to ensure the kitchen remains free from pests and potential infestations.

Types of Kitchen Audits

Understanding the different types of kitchen audits below will help you improve performance, safety, and efficiency.

Commercial Kitchen Inspection

A commercial kitchen inspection evaluates the overall condition and functionality of your kitchen. It focuses on the layout, workflow, ventilation, drainage, and lighting. It ensures your kitchen design supports safe food handling and prevents cross-contamination. Inspectors also check that cooking, preparation, and storage areas comply with local health codes and building regulations.

Commercial Kitchen Equipment Inspections

This audit examines the condition and performance of your kitchen equipment. It includes ovens, fryers, refrigerators, and dishwashers. It verifies that all appliances are working efficiently, calibrated correctly, and maintained regularly. This kitchen inspection also identifies worn-out or unsafe equipment that could cause food contamination or operational downtime. Regular equipment audits extend appliance lifespan and reduce energy costs.

Kitchen Hygiene Inspection

A hygiene inspection focuses on cleanliness and sanitation across all kitchen areas. It assesses food preparation surfaces, utensils, waste disposal systems, and pest control measures. It ensures cleaning schedules are followed, and hygiene practices meet regulatory standards. Maintaining a high level of cleanliness prevents foodborne illnesses and strengthens your compliance with health authorities.

Kitchen Health and Safety Inspections

Health and safety inspections identify hazards that could harm staff or customers. They cover fire safety systems, ventilation, temperature control, and emergency procedures. It checks for proper signage, staff training, and use of personal protective equipment. By addressing safety gaps, you minimize workplace accidents and improve overall operational safety.

Kitchen Risk Assessments

A risk assessment identifies potential hazards and evaluates their likelihood and severity. It examines areas such as food storage, equipment use, chemical handling, and staff behavior. The goal is to implement control measures that reduce risk and maintain compliance with occupational safety and food safety standards. Regular assessments also help you create a safer working environment and avoid costly incidents.

Home Kitchen Inspections

Home kitchen inspections are designed for domestic kitchens, especially those used for home-based food businesses. It reviews hygiene standards, food storage practices, and equipment safety. It ensures that food is prepared and stored under safe conditions. Inspectors may also check water quality, waste management, and ventilation. Meeting these standards protects your household and customers from food-related risks.

How to Perform Internal Kitchen Audits?

Here’s how to perform internal kitchen audits effectively:

1. Set Clear Objectives

Start by defining the purpose of your audit. Determine what you want to achieve, whether it’s ensuring food safety compliance, improving workflow, or reducing food waste. Clear objectives guide your audit scope and make it easier to measure results.

2. Use Digital Checklists to Perform Regular Audits

Adopt digital audit tools or software to streamline the process. Digital checklists ensure consistency, reduce human error, and simplify data collection. Schedule regular audits: daily, weekly, or monthly, based on your kitchen’s size and risk level.

3. Interview Staff and Observe Operations in Real Time

Speak directly with kitchen staff to understand their daily routines and challenges. Observe how food is stored, prepared, and served. Real-time observation helps you assess whether employees follow standard operating procedures and hygiene practices.

4. Review Previous Kitchen Audit Reports and Documentation

Analyze past audit reports, maintenance logs, and temperature records. Reviewing historical data helps you identify recurring issues and measure improvement trends. Ensure that all documentation complies with regulatory requirements.

5. Identify Risks and Non-Compliances

During the audit, note any deviations from safety standards or internal policies. Common non-compliances include poor food storage, improper sanitation, and inadequate record-keeping. Prioritize risks based on severity to address the most critical ones first.

6. Take Corrective Actions

Develop a clear action plan to resolve identified issues. Assign responsibilities, set deadlines, and provide training where necessary. Corrective actions should be practical, measurable, and focused on preventing recurrence.

7. Follow Up and Monitor Improvement Over Time

Track the implementation of corrective measures and monitor progress. Schedule follow-up audits to verify compliance and ensure improvements are sustained. Continuous monitoring reinforces accountability and supports long-term operational excellence.

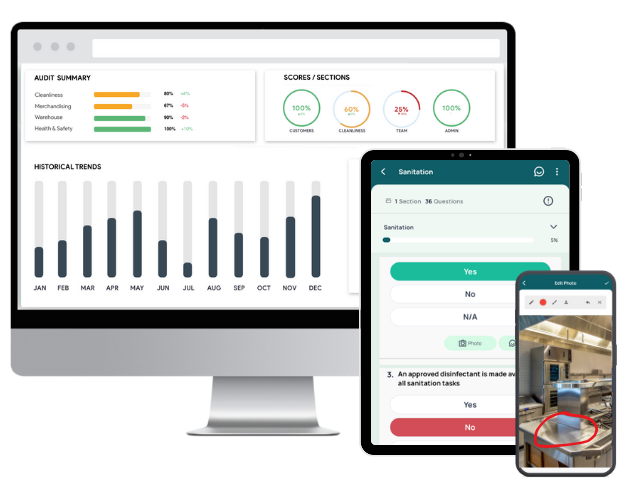

How GoAudits Simplifies Kitchen Inspections

GoAudits is an all-in-one mobile auditing app that makes kitchen compliance simple and reliable. Replace paper checklists with digital inspections, track issues in real time, and ensure every corrective action gets completed. This food safety software automatically generates audit trails and professional reports, helping you maintain hygiene and safety standards across all your sites.

- Use an intuitive mobile app to perform audits offline, attach annotated photos, and submit instantly.

- Capture photo evidence, timestamps, e-signatures, and geo-locations to create transparent, verifiable records for any external audit or inspection.

- Automatically produce branded, professional reports with actionable insights to drive continuous improvement and compliance.

- Assign corrective actions during inspections and track them through automated reminders until completion, ensuring no issue is overlooked.

- Access centralized dashboards to monitor performance trends, recurring issues, and audit scores across multiple kitchens or sites.

Free & Customizable Kitchen Inspection Checklists

Sign up for free and access a wide range of food safety audit checklists, or you can even digitize your existing forms and food SOPs.

- Daily Kitchen Cleaning Log

- Restaurant Kitchen Cleaning Checklist

- Kitchen Closing Checklist

- Commercial Kitchen Cleaning Checklist – Daily

- Monthly Commercial Kitchen Maintenance Checklist

- Kitchen Equipment Maintenance Checklist

- Food Safety Kitchen Inspection Checklist

- WHS Kitchen Hazard Inspection Checklist (Australia)

- Kitchen SOP Checklist

- Kitchen Quality Control Checklist

Common Kitchen Hazards List & Issues Found During Kitchen Inspections

Let’s look at some common kitchen hazards and issues identified during audits.

| Kitchen hazard | Description | Issues identified during inspections |

| Slippery Floor | Wet or greasy floors are a leading cause of slips and falls. | Spilled liquids, food residues, and poor drainage often contribute to this hazard. |

| Fire Hazards | Unattended stoves, faulty gas lines, and the accumulation of grease increase fire risks. | Inspectors often find missing fire extinguishers or poorly maintained suppression systems. |

| Poor Food Storage | Improper storage leads to cross-contamination and foodborne illnesses. | Common issues include incorrect temperature control, expired ingredients, and mixing raw and cooked items. |

| Electrical Hazards | Faulty electrical systems and equipment create significant safety risks in kitchens. | Overloaded outlets, exposed wiring, and malfunctioning appliances are frequent electrical risks. |

| Improper Ventilation | Inadequate ventilation allows heat, smoke, and fumes to build up. | Poor exhaust system maintenance can affect air quality, staff comfort, and lead to grease accumulation, a fire risk. |

| Blocked Pathways | Cluttered or obstructed walkways increase the risk of accidents and slow emergency evacuation. | Boxes, cleaning equipment, and delivery items often block aisles or exits, creating unnecessary hazards. |

| Unsafe Knife Handling | Improper knife use or storage causes frequent kitchen injuries. | Inspectors often find dull blades or knives left on countertops. |

| Pest Infestation | Unsealed food, waste buildup, and poor sanitation attract pests. | Signs of infestation, droppings, nests, or chewed packaging are some common issues. |

| Lack of Personal Hygiene | Poor hygiene among kitchen staff can lead to food contamination. | Not washing hands or wearing unclean uniforms are common issues during inspections. |

Kitchen Hygiene Standards: What Inspectors Look For

Maintaining proper kitchen hygiene standards is essential for food safety and regulatory compliance. Health inspectors evaluate various factors to ensure your kitchen meets required cleanliness and safety standards. Understanding what they look for helps you maintain consistent hygiene and prevent costly violations.

Core Kitchen Cleanliness Rules & Guidelines

Inspectors assess both the physical condition of the kitchen and how staff handle food. Key hygiene rules include:

- Clean Surfaces and Equipment: All food contact surfaces, utensils, and equipment must be cleaned and sanitized regularly. Cutting boards, knives, and countertops should be disinfected between uses to prevent bacterial growth.

- Proper Waste Disposal: Waste bins must be covered, emptied frequently, and kept away from food preparation areas. Food waste should never accumulate, as it attracts pests and contaminates the environment.

- Personal Hygiene Practices: Food handlers must wash their hands frequently, wear clean uniforms, and use gloves when necessary. Hairnets and beard covers are required to prevent contamination.

- Temperature Control: Food must be stored, cooked, and held at safe temperatures. Inspectors check refrigerator logs, thermometer accuracy, and cooling practices to prevent bacterial growth.

- Pest Control Measures: Kitchens must have effective pest prevention systems. Inspectors look for droppings, entry points, or signs of infestation, which indicate poor maintenance.

- Cross-Contamination Prevention: Separate raw and cooked foods, use color-coded chopping boards, and sanitize tools after handling raw meat, seafood, or poultry.

Importance of Kitchen Cleanliness Standards for Food Safety

Strict cleanliness standards protect customers and uphold your establishment’s reputation. Poor hygiene can lead to foodborne illnesses, regulatory penalties, and loss of business. Consistent cleaning routines reduce microbial risks, ensure safe food preparation, and maintain compliance with local health codes.

A hygienic kitchen also improves operational efficiency. Staff can work more effectively in a clean, organized space, reducing the chance of accidents or contamination during busy hours.

Common Kitchen Hygiene Violations

Inspectors frequently report violations that compromise food safety. Some common issues include:

| Cross-Contamination | Using the same utensils for raw and cooked foods or storing raw meat above ready-to-eat items. |

| Dirty Equipment or Surfaces | Failing to sanitize tools, cutting boards, or workstations regularly. |

| Inaccurate Temperature Logs | Missing or falsified records of refrigeration or cooking temperatures. |

As discussed above, other common kitchen hazards include poor personal hygiene, pest infestation, and improper food storage.

Maintaining kitchen hygiene is not a one-time effort but an ongoing responsibility. Using a digital inspection tool like GoAudits can streamline this process by enabling real-time audits, automated checklists, and corrective action tracking to ensure full compliance and consistent hygiene performance.