In environments like laboratories, manufacturing units, or research facilities, which handle and regularly use chemicals and other hazardous substances, following SOPs becomes essential. Chemical SOPs act as detailed, step-by-step guidelines for lab supervisors, technicians, researchers, and other employees who might be exposed to hazardous chemicals during their work. By standardizing procedures, chemical SOPs ensure the safe handling, storage, and usage of chemicals, mitigate risks associated with chemical interactions, exposure, and environmental contamination, and safeguard personnel.

This article will explore how organizations can prevent accidents, maintain compliance with regulatory standards, and promote a culture of safety with a step-by-step guide to develop and implement chemical SOPs. We have also listed free chemical SOP templates to help you get started.

What are Chemical SOPs?

Chemical standard operating procedures (SOPs) are written instructions that detail how to safely handle, use, store, and dispose of hazardous chemicals in laboratory or industrial settings. They are a foundational part of chemical safety programs and are required by regulatory agencies such as OSHA to ensure the health and safety of personnel working with hazardous substances.

The Principal Investigator (PI) or laboratory supervisor is responsible for ensuring that SOPs are developed, reviewed, and approved for all hazardous chemicals in their area.

Why are Chemical SOPs Important?

Here are some reasons why chemical safety SOPs are important.

- Chemical SOPs ensure compliance with regulations such as OSHA’s Process Safety Management (PSM) standard. Non-compliance can lead to legal penalties and financial liabilities.

- Chemical handling SOPs outline procedures to handle chemicals safely. They help identify potential hazards and implement control measures, reducing the risk of accidents and exposures, creating a safer work environment, and minimizing the health risks associated.

- Well-structured chemical SOP templates standardize operations, ensuring that tasks are performed uniformly across the organization. This not only streamlines the audit and inspection processes but also minimizes variability, reduces errors, and enhances the quality of outcomes.

- They provide clear and concise instructions, facilitating effective communication among team members. They serve as a reference point for procedures, ensuring that all employees understand their roles and responsibilities.

- By outlining step-by-step procedures, chemical SOP templates improve operational efficiency and accuracy, leading to improved productivity and cost savings. They reduce the likelihood of errors, minimize waste, and optimize resource utilization.

- Chemical SOPs include protocols for emergency situations, enabling prompt and effective responses to incidents involving hazardous chemicals. They help identify potential risks and implement preventive measures, mitigating the impact of emergencies on personnel and property.

- Chemical SOPs provide comprehensive training materials on safe practices and procedures for new and existing employees, ensuring they are well informed and competent in their roles.

Types of Chemical SOPs

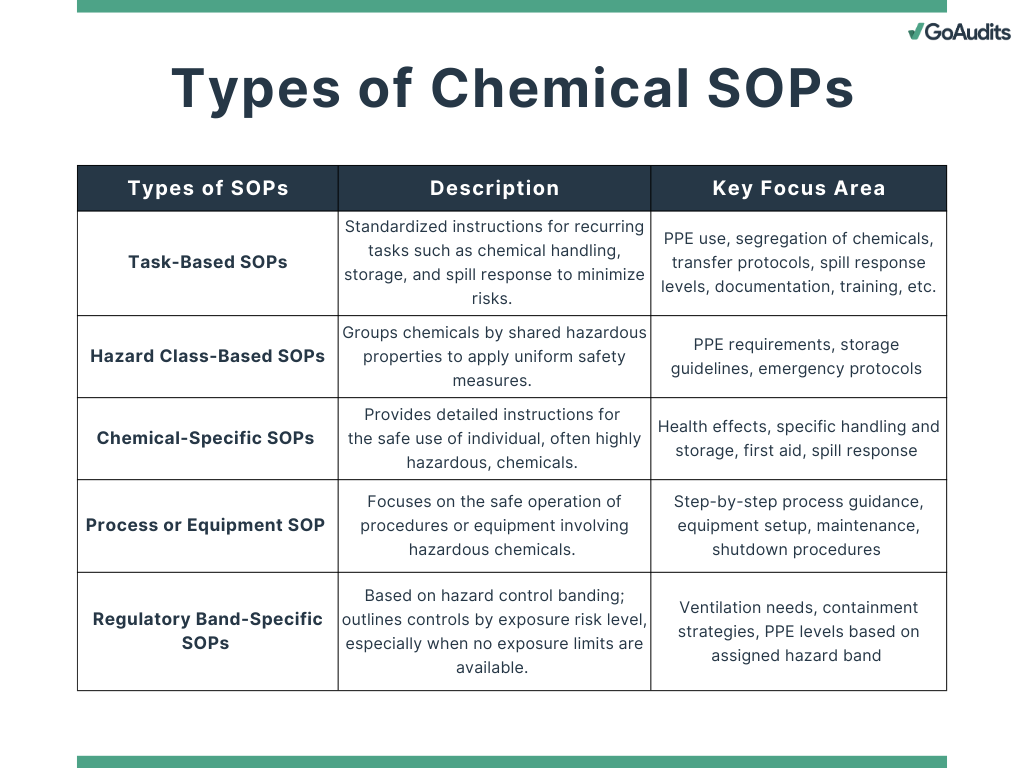

Primarily, chemical SOPs are classified into three different categories based on tasks, including SOPs for chemical handling, storage, and spillage response.

Chemical Handling SOP

Chemical handling SOPs provide standardized instructions to ensure the safe transfer, use, and management of chemicals during operational tasks. They begin with mandatory use of PPE as specified in each chemical’s safety data sheet (SDS).

SOPs for handling chemicals detail the correct methods for transferring chemicals, such as using secondary containment and avoiding overfilling. Chemical handling SOPs also stress the importance of using compatible materials, properly sealing containers, and maintaining clear labeling.

Chemical Storage SOPs

Chemical storage SOPs outline best practices for organizing and storing chemicals to ensure stability, prevent degradation, and reduce accident risks. The procedures begin by specifying appropriate storage containers and labeling practices. Every chemical must be clearly labeled with its identity, hazard class, and the date of receipt or opening. Chemicals prone to degradation are to be prioritized for usage or safely discarded within defined timelines. SOPs for chemical storage also also specifies that chemicals should not be stored in fume hoods, cold rooms, or above eye level.

Chemical Spill SOPs

Chemical spill SOPs offer detailed procedures for responding to accidental spills and releases of hazardous substances. They categorize spills based on volume and severity and outline the appropriate level of response for each type. Spills are typically classified as small, medium, or large.

SOPs for chemical spillage detail specific cleanup procedures based on spill size. For small spills, trained staff use absorbents, neutralizers, and proper PPE. Medium and large spills involve coordinated responses, often requiring the shutdown of ventilation systems and intervention by emergency teams. Post-cleanup steps include proper disposal of all contaminated materials as hazardous waste, area decontamination, and documentation.

In addition to the ones above, chemical SOPs can also be classified into the following categories.

Hazard Class-Based SOPs

Hazard class-based SOPs focus on groups of chemicals that share similar hazardous properties, such as flammability, toxicity, or corrosivity. These SOPs outline general safety measures applicable to the entire class, including appropriate personal protective equipment (PPE), storage requirements, and emergency procedures.

For instance, SOPs for flammable liquids would address proper storage in flammable cabinets, the use of flame-resistant PPE, and protocols for spill response. It streamlines safety practices for chemicals with common hazards, ensuring consistent risk management across similar substances.

👉 Find out how COSHH assessment software can help you simplify the process of identifying hazards and evaluating and controlling risks associated with hazardous substances used in different workplaces.

Chemical-Specific SOPs

Chemical-specific SOPs provide detailed safety instructions for individual chemicals, particularly those classified as highly hazardous. SOPs include comprehensive information on the chemical’s properties, potential health effects, specific handling procedures, storage conditions, and emergency response actions.

For example, an SOP for hydrofluoric acid would detail its corrosive nature, the necessity for specialized PPE, and immediate steps to take in case of exposure. Chemical-specific SOPs ensure that unique risks associated with particular substances are adequately addressed, enhancing overall safety.

Process or Equipment SOPs

These SOPs are tailored to specific laboratory procedures or equipment operations involving hazardous chemicals. They outline step-by-step instructions for safely conducting processes such as distillation, chromatography, or the use of autoclaves. They include details on equipment setup, operational parameters, maintenance routines, and shutdown procedures. Focusing on the procedural aspects, these chemical SOPs help prevent accidents related to equipment misuse or procedural errors.

Regulatory Band-Specific SOPs

Regulatory band-specific SOPs are developed based on control banding strategies, which categorize chemicals according to their hazard levels and corresponding exposure control measures. This method is particularly useful when specific occupational exposure limits are unavailable. These SOPs outline the necessary controls, such as ventilation requirements, containment strategies, and PPE, based on the assigned hazard band.

For instance, a chemical assigned to a high-hazard band would necessitate stringent containment and specialized PPE. This ensures proactive risk management, especially for new or less-studied chemicals.

Key Components of Chemical SOP Templates

A well-constructed chemical SOP contains several essential components, including the following:

Purpose and Scope

Every chemical SOP begins with a clearly defined purpose and scope. It explains why the procedure exists and what activities, chemicals, and personnel it covers. It sets expectations for applicability, ensuring that all users understand the boundaries and relevance of the SOP to their tasks.

Safety Guidelines and Precautions

Chemical SOPs incorporate a comprehensive list of safety guidelines and precautions. It outlines specific hazards associated with the chemicals, mandates the use of appropriate personal protective equipment (PPE), describes necessary engineering controls like fume hoods, and emphasizes safe handling practices to minimize risks.

Roles and Responsibilities

This section of a chemical SOP template assigns duties to all individuals involved in chemical handling, storage, and disposal. Responsibilities may include conducting risk assessments, maintaining safety equipment, providing training, and responding to emergencies.

Equipment and Materials

A chemical SOP includes a detailed list of equipment and materials required to perform the procedure safely and effectively. This section specifies equipment types, operational instructions, and maintenance requirements, ensuring only suitable, functioning equipment is used.

Storage Procedures

SOPs for chemical storage describe proper storage conditions, such as temperature, ventilation, and segregation of incompatible substances. Chemical storage SOPs also outline labeling requirements and organizational methods to prevent cross-contamination, leaks, or other hazardous incidents.

Handling and Transfer Techniques

Handling and transferring chemicals involve inherent risks. Detailed techniques for safe measurement, mixing, and transport of chemicals are provided in this section. It also emphasizes the use of secondary containment, specialized tools, and methods that minimize exposure, spills, or unintentional releases.

Emergency Response (Spill and Exposure)

Chemical spill SOPs outline immediate actions to take in case of spills, leaks, or accidental exposures. It describes evacuation procedures, decontamination processes, first aid measures, and the use of emergency equipment such as eyewash stations and spill kits.

Waste Management and Disposal

This section of chemical SOP templates provides guidance on the collection, segregation, labeling, and storage of chemical waste. It ensures that disposal methods comply with regulatory requirements and promotes practices that minimize environmental impact and reduce hazardous waste generation.

Documentation and Records

A chemical SOP specifies the types of records that must be kept, such as training logs, inspection reports, incident documentation, and waste disposal records to demonstrate compliance and improve chemical safety practices in your workplace. It also establishes procedures for regularly reviewing and updating the chemical SOP to reflect changes in regulations, practices, or organizational needs.

How to Create & Use Chemical SOPs in 9 Steps?

Here’s a step-by-step guide to create and start using chemical SOPs.

1. Identify Chemicals and Processes

Begin by compiling a comprehensive inventory of all chemicals used in your laboratory to ensure that all hazardous materials and associated procedures are accounted for in your SOPs. Categorize them based on their hazard classifications. Additionally, document all processes involving these chemicals, including synthesis, analysis, storage, and disposal.

2. Assess Hazards and Risks

For each chemical and process, conduct a thorough hazard assessment. Use safety data sheets (SDS) to identify potential health risks, environmental impacts, and physical hazards. Evaluate the likelihood and severity of incidents to prioritize risk mitigation strategies.

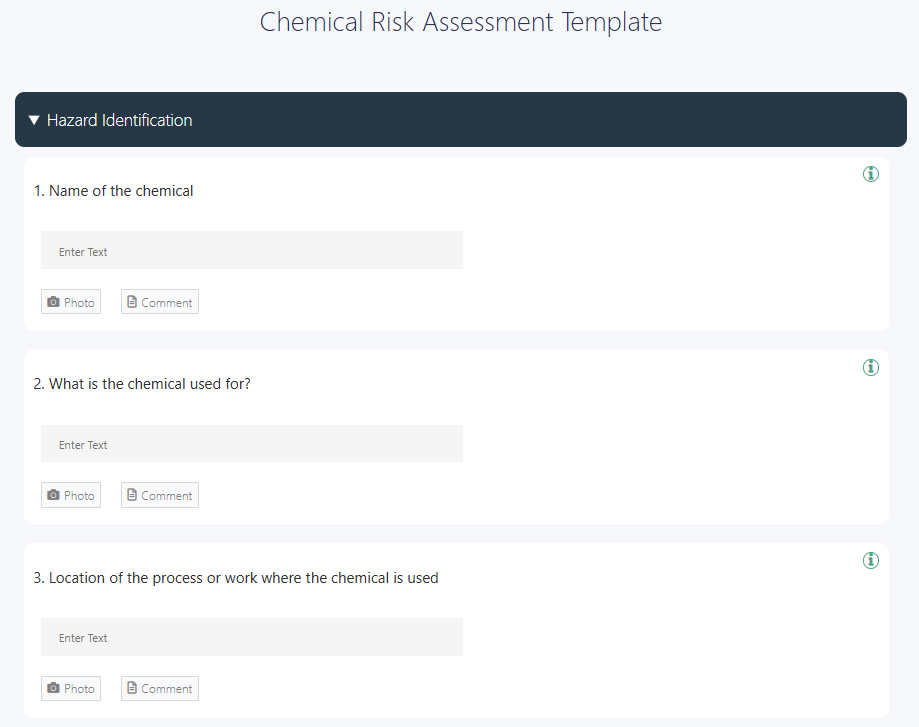

👉 Use this GoAudits free chemical risk assessment template to identify and prevent potential hazards, ensure the proper containment and disposal of chemicals, and reduce risks.

3. Define the Scope and Objective

Clearly articulate the purpose of each chemical SOP, specifying the activities it covers and the intended outcomes. Define the boundaries of the procedure, including any limitations or exclusions. A well-defined scope ensures that users understand the applicability of the SOP and adhere to its guidelines.

4. Gather Essential Information

Before you write your chemical SOPs, you need to collect reliable and detailed information that will guide the procedure. This includes:

- The information provided by the chemical suppliers. They explain how to handle, store, and dispose of chemicals safely.

- Your organization’s internal safety policies and national regulations (like OSHA, EPA, REACH, etc.).

- Industry standards, scientific guidelines, or professional associations to find the safest and most effective methods for handling, using, storing, and disposing of chemicals and performing chemical-related processes in your laboratory or workplace.

- Consult senior lab workers, safety officers, or process engineers to learn about practical safety tips.

Ensure that the information is accurate, up-to-date, and relevant to your specific laboratory context.

5. Draft the Chemical SOP

Develop a detailed, step-by-step procedure that outlines the safe handling, use, and disposal of chemicals. Use clear, concise language and consider incorporating diagrams or flowcharts to enhance understanding.

6. Use Digital Checklists and Templates

Use digital, standardized chemical SOP templates to ensure consistency across documents, simplify the process of inspections and audits, and facilitate real-time tracking of compliance and task completion.

GoAudits offers a wide range of chemical SOP templates. You can sign up for free and start using these checklists. Alternatively, you can customize these templates to meet your organizational and industry standards.

- Chemical Safety Checklist – COSHH

- Chemical Risk Assessment Template

- HSE COSHH Assessment Template

- MSDS Checklist – COSHH

7. Review and Approve

Conduct a comprehensive review of the drafted chemical SOPs with relevant stakeholders. Ensure that the procedures align with institutional policies and regulatory standards. Obtain formal approval from authorized personnel before implementation.

8. Train Employees

Provide thorough training to all employees on the new SOPs. Use a combination of instructional methods, such as workshops, demonstrations, and assessments, to reinforce understanding. Document training sessions and maintain records of employee competency.

9. Monitor and Update

Establish a system for ongoing monitoring of chemical SOP effectiveness. Regularly review procedures to incorporate changes in regulations, technology, or laboratory practices. Request feedback from personnel to identify areas for improvement. Maintain a revision history to track updates and ensure that all users have access to the most current version.

👉 How often should chemical SOPs be reviewed and updated?

Chemical SOPs should be updated:

– Whenever procedures, processes, or hazards change

– After incidents or unexpected outcomes

– Addition or removal of chemicals or equipment

– When new personnel join or new templates are issued

– Scheduled periodic reviews, once or twice a year

Digitize Your Chemical & Safety SOPs with GoAudits

Chemical SOPs ensure consistent processes, compliance with regulations, and, most importantly, the safety of your teams. However, relying on paper-based, chemical SOP templates often leads to inefficiencies, errors, and compliance risks. If you are still managing your chemical SOPs manually, it is time to consider a smarter alternative.

GoAudits safety inspection software is a comprehensive solution to digitize, streamline, and strengthen your chemical safety operations in your workplace.

- Digitizing your chemical SOPs with GoAudits transforms static documents into dynamic, interactive processes. It eliminates manual errors, reduces administrative burdens, and ensures real-time compliance. You can standardize procedures across locations, departments, and teams effortlessly.

- Every team member can easily access the latest chemical SOP templates via mobile devices. You can perform safety inspections on the go, even in offline mode.

- After each inspection or audit, GoAudits automatically generates professional, customizable reports. You can configure reports to highlight key findings, non-conformities, and corrective actions, and share them with relevant stakeholders.

- Non-compliance or deviation from chemical SOPs demands swift action. You can assign corrective actions to specific team members during inspections, set deadlines, send notifications, and escalate unresolved issues automatically.

- Involve the right people at the right time by setting up workflows for approvals, tasks, reminders, and report distribution.

- GoAudits’ smart dashboards offer insights into audit scores and performance. It can help you visualize operational data to analyze trends and patterns, identify recurring issues, monitor key performance indicators (KPIs), and predict future risks. You can refine your chemical SOPs, optimize resource allocation, and strengthen your safety and quality programs.