Equipment failure can lead to costly downtime, legal consequences, or serious accidents. Equipment and machinery-related incidents are the third-leading cause of occupational fatalities in the US. Almost 3,700 workers died due to contact with workplace equipment and objects between 2018 and 2022. Over 12% of all work-related fatalities were attributed to machinery-related incidents in 2022 alone. That’s why regular equipment inspections are non-negotiable. However, many organizations still rely on manual, paper-based processes. They are prone to errors, delays, and inconsistencies. Tracking recurring issues or analyzing long-term trends becomes difficult. Digitizing equipment safety inspections addresses these challenges by standardizing reporting, capturing real-time data, and ensuring accountability. Digital solutions streamline the entire process, making it faster, more reliable, and easily auditable.

This article will explore the types and steps to perform equipment safety inspections. We have also included free checklists to perform these inspections and a free equipment inspection report sample.

- What is an Equipment Inspection?

- Key Aspects to Be Inspected During Equipment Inspections

- Types of Equipment Inspections

- Steps to Perform Equipment Inspections

- Free Equipment Inspection Report Sample

- Perform Equipment Safety Inspections with GoAudits

- Why is an Equipment Inspection Report Important?

- How to Prepare an Equipment Inspection Report?

What is an Equipment Inspection?

An equipment inspection is a systematic process of assessing machinery, tools, or devices to ensure they are operating safely, efficiently, and in compliance with regulations. The goal is to identify signs of wear, damage, or potential failure before they lead to costly breakdowns or accidents.

They focus on checking structural integrity, performance, alignment, lubrication, and safety features. Depending on the type of equipment, this may involve visual checks, functional tests, measurements, or diagnostic scans. Equipment inspections can be routine, periodic, or condition-based, and they form an important part of any preventive maintenance strategy.

The responsibility to perform equipment safety inspections often falls on:

- Maintenance technicians perform routine and condition-based checks.

- Operators for daily pre-use inspections.

- Safety officers or compliance managers are responsible for periodic audits.

- Third-party certified inspectors for regulated equipment or insurance purposes.

Yes, OSHA requires that equipment be inspected regularly to ensure safe operation and compliance with safety standards. The specific frequency and type of inspection depends on the equipment and industry, but inspections must be documented, performed by qualified individuals, and address potential hazards to prevent accidents, with stricter guidelines and mandatory checks for construction and heavy equipment, as well as requirements for maintaining inspection records and taking corrective actions when issues are found.

Benefits of Equipment Safety Inspections

Here’s how consistent inspections benefit your operations:

- Identifying and addressing risks promptly, you protect workers from harm and reduce the likelihood of workplace injuries.

- Routine equipment inspections help detect minor faults before they turn into major problems. As a result, maintenance can be scheduled in advance, reducing unplanned outages and keeping equipment running when it’s needed most.

- Equipment safety inspections ensure all machinery operates at peak performance, preventing downtime that can affect delivery schedules.

- Equipment inspections allow you to catch deteriorating parts, misalignments, or leaks before they require expensive intervention. Preventive action significantly reduces repair bills over time.

- Inspections enable proactive care, reducing wear and avoiding premature failure. By ensuring all components are functioning as intended, you extend the usable life of machinery, maximizing your investment and delaying capital expenditure.

- Regulatory bodies like OSHA and ISO mandate equipment inspections for safety and environmental standards. Regular checks help you stay compliant, avoid legal penalties, and maintain certification. They also provide documented proof of due diligence during audits or incident investigations.

- Routine inspections support a predictive maintenance approach. By monitoring performance trends and identifying recurring issues, you can plan more efficiently, reduce emergency repairs, and allocate maintenance budgets more effectively.

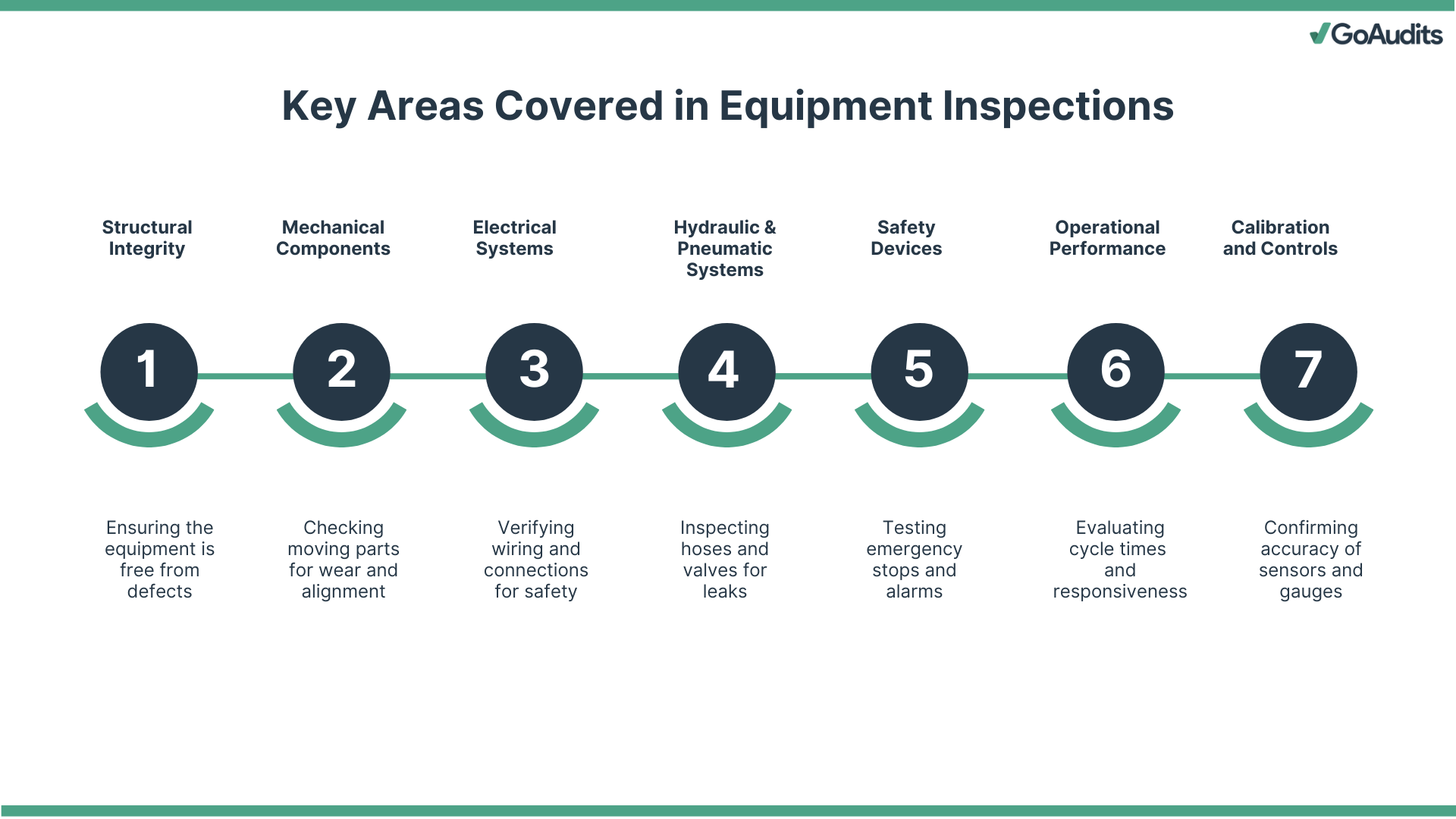

Key Aspects to Be Inspected During Equipment Inspections

Focus on the following key aspects during every equipment safety inspection:

Structural Integrity

Start by examining the equipment’s framework. Check for cracks, corrosion, or deformations in the structure. Look closely at welds, joints, fasteners, and mounting points. Weak or compromised structural elements can lead to catastrophic failures and safety hazards. Pay special attention to stress-bearing areas and components that undergo repeated load cycles.

Mechanical Components

Inspect all moving parts, such as gears, bearings, shafts, belts, chains, and couplings. Look for signs of wear, misalignment, or inadequate lubrication. Ensure that there’s no unusual noise or vibration during operation. Any deviation in mechanical performance often indicates deeper issues that need immediate attention.

Electrical Systems

Verify the condition and functionality of wiring, connections, circuit breakers, and control panels. Look for signs of overheating, frayed wires, or loose terminals. Ensure proper grounding and insulation. Malfunctions in the electrical system can lead to downtime, data loss, or severe electrical hazards. Use diagnostic tools to assess voltage levels, continuity, and load capacity.

Hydraulic and Pneumatic Systems

Check hoses, valves, pumps, and actuators for leaks, pressure drops, or damage. Monitor fluid levels and quality. In pneumatic systems, assess the condition of compressors and air lines. Ensure all components maintain the required pressure and respond accurately to control inputs. Delays or erratic movements often signal system inefficiencies or failures.

Safety Devices and Features

Review all safety mechanisms such as emergency stops, guards, interlocks, and alarms. Test them under simulated fault conditions. Make sure warning labels are visible and functional elements comply with regulatory standards. Never overlook these components as they protect operators and reduce liability.

Operational Performance

Observe the equipment during operation. Evaluate cycle times, responsiveness, and consistency under load. Compare actual performance against manufacturer specifications. Any irregularities, such as slow response, excessive noise, or overheating, should prompt further investigation.

Calibration and Controls

Confirm the accuracy of sensors, gauges, meters, and control systems. Calibrated equipment ensures reliable output and maintains process standards. Examine software interfaces, PLCs, and human-machine interfaces (HMIs) for errors or outdated programming. Incorrect calibration can lead to product defects and regulatory violations.

Types of Equipment Inspections

Understanding the different types of inspections can help you define the right inspection strategy for your equipment. There are different inspection types by equipment type, frequency, or inspection purpose:

By Equipment Type

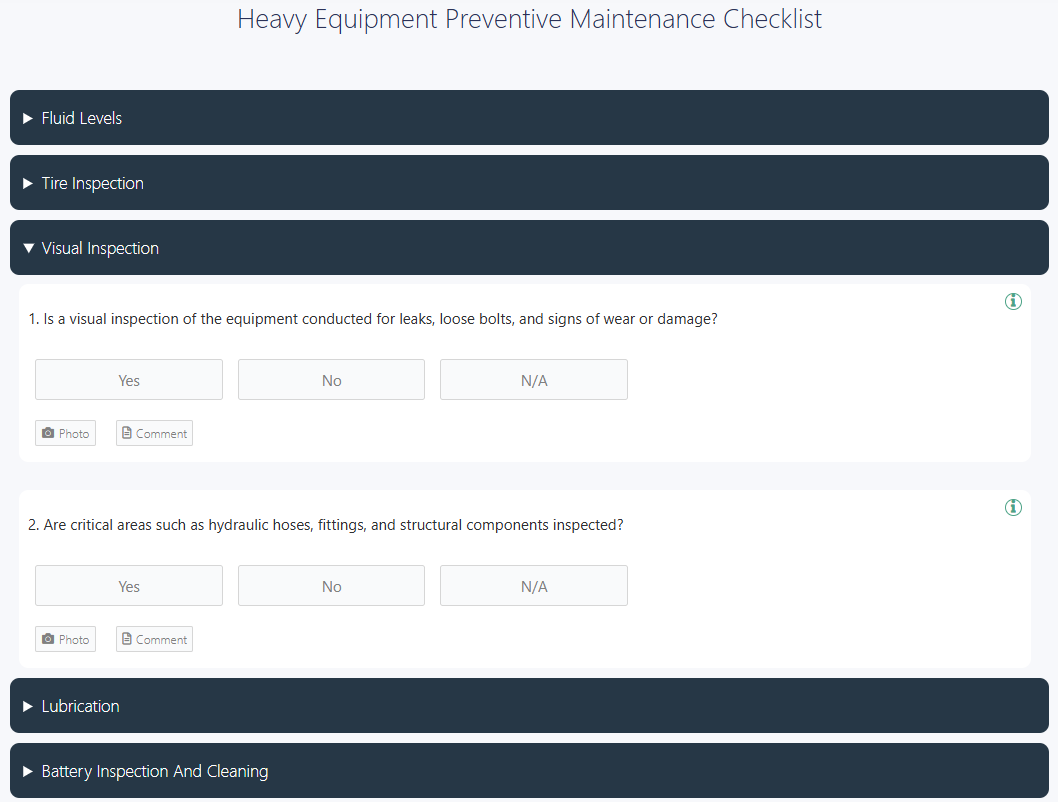

Heavy Equipment

Heavy machinery such as excavators, loaders, bulldozers, and cranes demands rigorous inspection protocols. You must assess structural integrity, hydraulic systems, braking systems, and control mechanisms. Wear and tear on critical components, especially under high-load conditions, should be closely monitored.

👉 Use this free GoAudits heavy equipment preventive maintenance checklist to ensure optimal performance and safety by performing routine inspections and checks.

Electrical Equipment

Electrical audits and inspections focus on wiring integrity, insulation resistance, circuit breakers, grounding, and overload protection. Thermal imaging is often used to detect overheating. Regular checks reduce fire risks and improve energy efficiency.

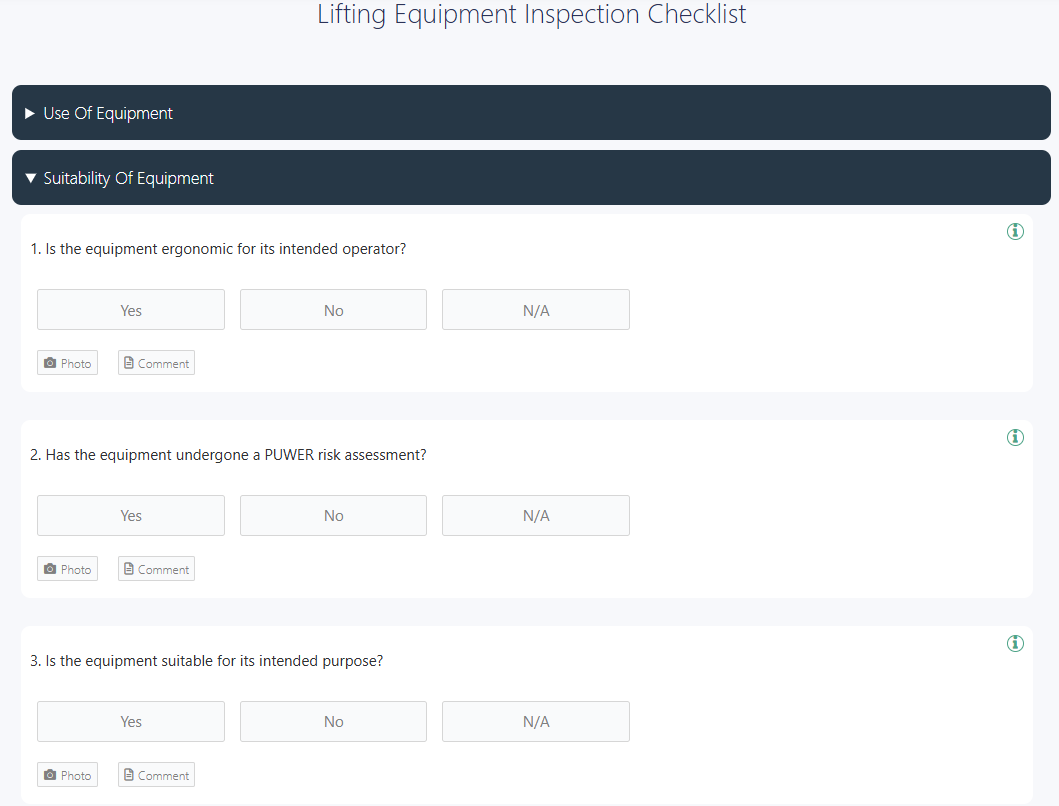

Lifting Equipment

Lifting gear, including hoists, forklifts, cranes, and slings, must be inspected for load-bearing capacity, deformation, corrosion, and safety lock functionality. You must confirm that all devices operate within rated capacities and comply with load-handling protocols.

👉 Use this free lifting equipment inspection checklist to assess key aspects like equipment condition, usage characteristics, and more, ensuring safety.

Mechanical Equipment

Mechanical assets, such as pumps, compressors, engines, and gear systems, require inspections focused on moving parts, lubrication systems, seals, and fasteners. Alignment, vibration levels, and operational noise also provide early signs of malfunction.

By Inspection Frequency

- Pre-Operation Audit: Before each use, conduct a brief audit to check for visible damage, fluid levels, and safety features. It helps you detect problems early and prevent immediate hazards.

- Routine Inspections (Daily, Weekly, Monthly): Routine checks help you identify wear trends and maintenance needs. Daily equipment inspections are often visual and functional, while weekly or monthly checks dive deeper into mechanical and electrical performance.

- Quarterly or Annual Inspections: They evaluate overall equipment health. You should include testing of safety systems, calibration of instruments, and in-depth component assessments. They align with warranty requirements and industry standards.

- Periodic or Scheduled Inspections: Based on manufacturer recommendations or operational hours, these inspections ensure timely maintenance. They provide structure to your maintenance plan and prevent overlooked issues.

- Condition-Based Inspections: Instead of relying on time intervals, condition-based inspections are triggered by performance metrics. Use sensor data or operator feedback to determine when checks are necessary. This method is efficient and cost-effective.

- Post-Incident Inspections: After any incident or near-miss, you must perform a thorough inspection. Assess the cause, document damages, and verify that the equipment is safe to resume operation. They are essential for root cause analysis and future prevention.

By Purpose

- Visual Inspection: This is the most basic yet crucial inspection type. Look for cracks, leaks, frayed wires, or misalignments. Visual inspections are often the first line of defense against failure.

- Functional Testing: Verify that equipment performs its intended function under normal and stress conditions. Test safety interlocks, emergency stops, and system response times.

- Preventive Maintenance: Scheduled tasks, such as lubrication, part replacement, and filter changes, fall under preventive maintenance. These inspections help you avoid unscheduled breakdowns.

- Predictive Maintenance: Using sensors and analytics, predictive inspections assess real-time data like vibration, temperature, and noise. These help you forecast failures before they occur, optimizing uptime and resource allocation.

- Equipment Safety Inspection: Focused on hazard identification, these inspections confirm that safety guards, emergency exits, warning labels, and personal protective features meet required standards.

- Compliance or Regulatory Audits: They ensure that your equipment meets health, safety, and environmental regulations. Non-compliance can lead to fines, operational shutdowns, or legal consequences. Always document these audits thoroughly.

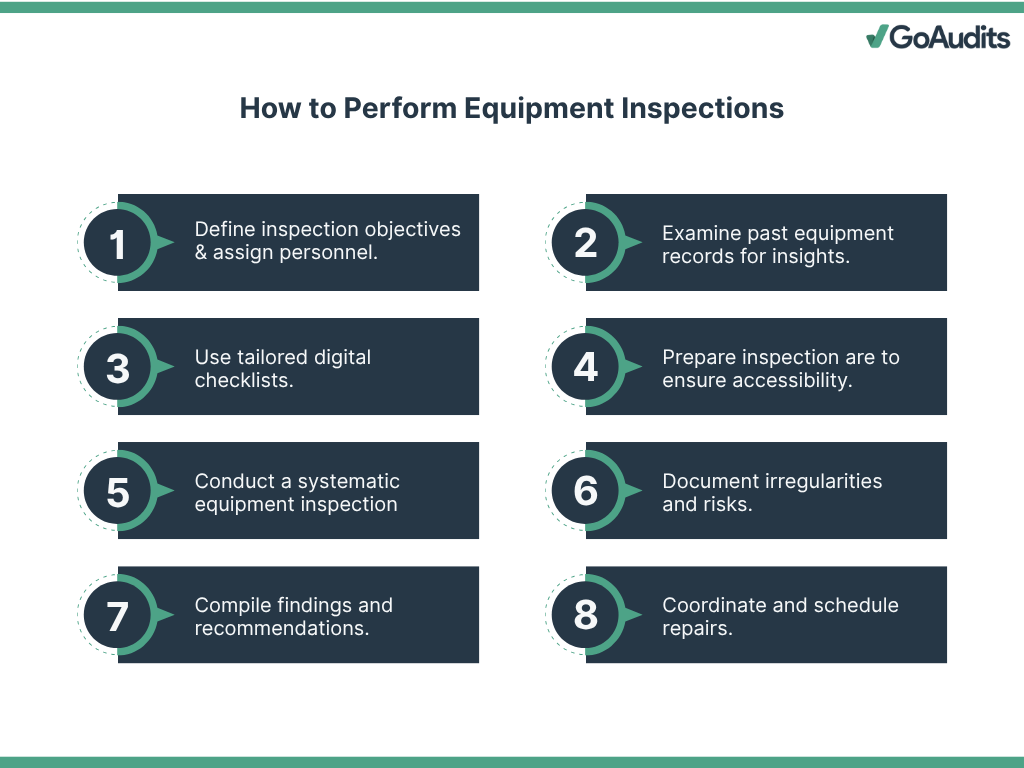

Steps to Perform Equipment Inspections

To conduct a reliable inspection, follow a structured process that ensures accuracy, consistency, and accountability.

1. Plan and Prepare for the Equipment Safety Inspection

Begin with a clear objective. Determine the purpose of the inspection, whether it’s routine, post-maintenance, or due to a performance issue. Define which equipment will be inspected and who will conduct the inspection. Assign trained personnel, set timelines, and ensure they understand the inspection scope and criteria.

2. Review Equipment History and Manual

Before you inspect, review the equipment’s maintenance logs, repair records, and past inspection reports. These documents reveal recurring issues or patterns of wear. Consult the manufacturer’s manual to understand operational specifications, inspection points, and critical safety measures. This step prevents oversights and aligns the inspection with original design standards.

3. Use Tailored, Digital Checklists

Generic checklists may overlook equipment-specific components. Use digital checklists tailored to each asset type. These should include step-by-step inspection points based on the equipment’s make, model, and use case. Digital formats reduce errors, ensure consistency, and allow real-time data entry, streamlining documentation and future audits.

👉 Free Resources

GoAudits offers the following equipment inspection checklists tailored for different equipment and industries. You can sign up for free and start using these checklists.

→ Equipment Inspection Form

→ OSHA Hand Powered Tools Checklist

→ Lifting Equipment Inspection Checklist

→ Machine Preventive Maintenance Checklist

→ Equipment Inspection Checklist – Gym

→ HVAC Maintenance Checklist Template

→ Heavy Equipment Preventive Maintenance Checklist

4. Prepare the Inspection Area

Create a safe and accessible environment around the equipment. Clear obstructions, ensure adequate lighting, and secure moving parts. If the equipment needs to be powered down, follow lockout/tagout procedures. This step minimizes risks to both inspectors and operational assets.

5. Perform a Thorough Equipment Inspection

Inspect the equipment systematically, starting from the exterior and working inward. Examine structural integrity, electrical components, hydraulic systems, and control interfaces. Check for signs of wear, corrosion, misalignment, and fluid leaks. Use diagnostic tools where necessary to verify internal conditions. Always follow the sequence outlined in the checklist.

6. Identify Hazards and Associated Risks

As you inspect, document any irregularities, malfunctions, or safety hazards. Evaluate the potential impact of each issue on safety, compliance, and performance. Classify risks as minor, moderate, or critical based on severity and likelihood. It supports informed decision-making for maintenance and repair.

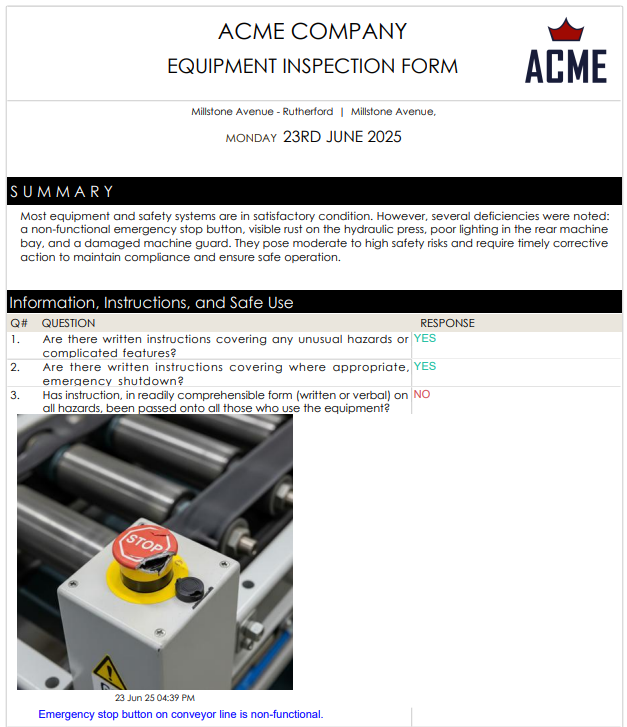

7. Prepare the Equipment Inspection Report

Document all findings in a structured report. Include equipment ID, inspection date, inspector’s name, checklist items, observed deficiencies, and risk levels. Use photos and diagnostic readings to support observations. Clearly note whether the equipment is safe to operate, requires monitoring, or must be taken out of service.

8. Schedule Repairs, Follow-Up, and Re-Inspect

Act promptly on the inspection findings. Coordinate with maintenance teams to schedule repairs or parts replacement. For critical issues, initiate corrective actions immediately. After repairs, conduct a re-inspection to verify resolution and restore compliance. Maintain a record of follow-up actions for traceability.

Free Equipment Inspection Report Sample

Here’s a free equipment inspection report sample generated using GoAudits:

Perform Equipment Safety Inspections with GoAudits

Maintaining equipment safety standards requires more than periodic checks; it demands consistency, precision, and actionable data. GoAudits safety inspection software enables you to perform equipment safety inspections efficiently. With an all-in-one mobile auditing platform, you can streamline every step of your inspection process, from checklist creation to task assignment and data analysis.

By digitizing and centralizing your equipment inspections, GoAudits helps you move from reactive fixes to proactive risk management, ensuring your operations are accountable and compliant. Here’s how you can reduce downtime, enforce compliance, and enhance workplace safety with GoAudits.

- Access ready-to-use safety inspection templates or create custom checklists tailored to your standards. Upload your existing formats, and GoAudits will digitize them for you, free of charge.

- Use any device to perform equipment inspections, even offline. Capture data, take photos, and annotate findings in real time, without relying on paper or spreadsheets.

- Automatically generate branded equipment inspection reports immediately after each inspection. Reports include timestamps, geo-locations, photos, and user details for full transparency.

- Assign corrective actions during inspections. Ensure full accountability with due dates, task owners, and real-time updates on status and completion.

- Automate follow-ups, approvals, and distributions. Configure workflows so that the right people are alerted, and no safety issue is overlooked.

- Monitor trends, identify recurring issues, and evaluate inspection scores across teams and sites. Use smart dashboards to make data-driven decisions and improve safety performance continuously.

Why is an Equipment Inspection Report Important?

An equipment inspection report is important for several reasons, including the following.

- Equipment inspection reports offer a reliable record of your equipment’s condition over time. Each entry creates a traceable history that supports audits, service planning, and insurance claims. With clear documentation, you reduce guesswork and build trust with stakeholders.

- Accurate data from these reports allows you to make informed decisions about repairs, replacements, or upgrades. When you understand the condition and performance of your equipment, you can allocate resources efficiently and avoid costly downtime.

- Regulatory bodies often require proof of regular equipment inspections. These reports act as evidence that you’re meeting industry standards and legal obligations. They help you avoid penalties and demonstrate a proactive approach to safety and compliance.

- A detailed maintenance history helps you identify recurring problems, track wear patterns, and schedule preventive maintenance. This extends the life of your equipment and improves operational efficiency.

- Machine inspection reports improve communication across teams. Technicians, supervisors, and safety officers can access the same information, reducing misunderstandings and ensuring consistent actions. Everyone stays aligned on equipment condition and next steps.

- Standardized equipment reports create accountability. When each inspection is logged, it’s clear who performed the task and when. This promotes consistency in maintenance routines and holds teams responsible for following safety protocols.

How to Prepare an Equipment Inspection Report?

Here’s how to prepare a comprehensive and actionable equipment inspection report.

Compile and Analyze Inspection Data

Start by gathering all relevant data collected during the inspection. This includes:

- Equipment ID and location

- Inspection date and time

- Inspector’s name and qualifications

- Checklists used

- Recorded observations

- Measurements and test results

- Photos or videos for visual evidence

Evaluate the data for accuracy and completeness. Identify discrepancies, irregularities, or patterns that may indicate equipment wear, failure, or safety concerns.

Use a Structured Equipment Inspection Report Template

Use a consistent equipment inspection format to ensure clarity and standardization. A professional equipment inspection report should include:

- Report title and reference number

- Inspection details (date, time, location, equipment type)

- Inspector’s details

- Purpose and scope of the inspection

- Checklist of items inspected

- Observations and findings (including visual and technical assessments)

- Photographic evidence

- Deficiencies or non-compliance issues

- Risk levels associated with each issue

- Comments or notes from the inspector

- Digital signatures for accountability

👉 GoAudits equipment inspection software can simplify this process by automatically generating customized reports after inspections.

Add Corrective Actions and Recommendations

Based on the findings, list the required corrective actions and improvement measures. Each action should be:

- Clearly defined and easy to understand

- Prioritized based on risk and urgency

- Assigned to responsible personnel

- Given a deadline for resolution

Include recommendations to prevent recurrence, improve equipment reliability, and ensure compliance with safety standards.

Review and Share the Equipment Inspection Report

Before distribution, review the report for completeness, accuracy, and clarity. Ensure:

- All sections are filled

- Attachments are in place

- Terminologies are consistent

- Sensitive data is handled appropriately

Once reviewed, share the machine inspection report with stakeholders such as maintenance teams, supervisors, and compliance officers.

Initiate Follow-Up

Monitoring the implementation of corrective actions is essential. Track:

- Completion status

- Feedback from responsible teams

- Delays or issues in resolution

Schedule follow-up equipment inspections if needed to verify that corrective actions have been implemented effectively.

Evaluate Outcomes

Assess whether the measures taken have resolved the identified issues. Use the results to:

- Improve future inspection checklists

- Adjust maintenance schedules

- Update training materials for inspection staff

- Enhance equipment management strategies

With GoAudits, you can automate report generation, customize report formats, and streamline sharing. This not only saves time but also improves consistency and accountability.