Manual, paper-based electrical inspection reporting poses significant challenges. It’s time-consuming, error-prone, and often results in misplaced data or inconsistent documentation. Navigating handwritten notes, scanning forms, and filing physical copies creates inefficiencies that can delay compliance, compromise accuracy, and hinder decision-making. Digital reporting solutions address these issues with streamlined processes, real-time data capture, and centralized record-keeping. Eliminating manual steps can reduce human error, ensure consistent standards, and improve accessibility across teams. A digital approach to generating an electrical inspection report is essential for operational efficiency and regulatory accuracy.

This article will explore the key components and steps to prepare an electrical audit report. We have also listed free checklists to help you perform inspections and generate reports, as well as a free report sample.

What is an Electrical Inspection Report?

An electrical inspection report is a formal document that details the findings of an electrical audit or inspection of a property’s electrical system. Its primary purpose is to assess the safety, condition, and compliance of electrical installations, identifying any hazards, defects, or areas that require improvement to ensure the system is safe for continued use.

Why are Electrical Audit Reports Important for Workplace Safety?

Here’s why it matters:

- Act as official records demonstrating adherence to safety regulations and electrical standards.

- Provide comprehensive data and analysis to help you plan upgrades, repairs, or system changes effectively.

- Offer a reliable point of reference for future audits, inspections, or troubleshooting.

- Act as credible documentation in the event of disputes, accidents, or insurance claims.

- Hold maintenance teams and service providers responsible through written findings and recommendations.

- Help allocate resources efficiently by highlighting priority areas for investment or repair.

- It allows you to compare historical data and assess improvements over time.

- Facilitate clear communication between safety officers, facility managers, and stakeholders.

- Provide auditors with structured, easy-to-review evidence of safety practices and system integrity.

Free Electrical Inspection Report Template

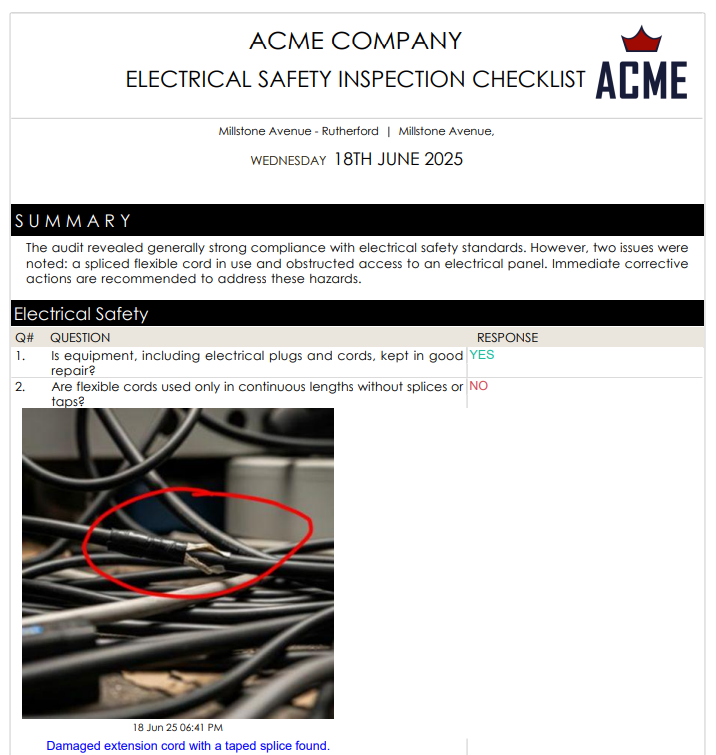

Here’s an electrical safety audit report sample generated with GoAudits.

Key Components of Electrical Inspection Report Template

A comprehensive electrical inspection report template includes the following components.

Executive Summary

This section offers a high-level overview of the inspection. It briefly outlines the purpose, scope, and major findings. Key risks, urgent issues, and general system health are summarized to help stakeholders quickly grasp the critical insights without reading the full electrical inspection report.

Methodology of the Inspection Process

Here, the electrical audit report outlines the approach and criteria used during the inspection. It details the relevant standards referenced, alongside the tools, testing instruments, and techniques applied. The methodology also defines the physical areas and electrical components evaluated, from main switchboards to sub-circuits and grounding systems.

Detailed Findings

This section of the electrical safety report documents the actual conditions observed. It includes a comprehensive evaluation of equipment status, wiring integrity, labeling, distribution systems, and protective devices. Any signs of overheating, wear, improper installation, or non-compliance are recorded. Findings should be factual, specific, and well-organized to allow readers to clearly identify the nature and extent of any issues.

Risk Assessment and Coding

Each observation is assigned a risk code to prioritize action, aligning the coding system with industry standards:

- C1 – Danger Present: Immediate risk requiring urgent isolation or repair.

- C2 – Potential Danger: A defect likely to become hazardous if left unaddressed.

- C3 – Improvement Recommended: No immediate risk, but the system could be safer or more compliant.

- FI – Further Investigation Required: Used where a complete assessment was not possible without additional testing.

Each observation receives only the highest applicable code, which ensures consistency and facilitates prioritization.

Recommendations

This section provides practical guidance based on the risk assessment. For C1 and C2 issues, immediate or timely corrective actions are proposed. C3 observations may include suggestions for future upgrades or enhancements, such as replacing aged conductors or updating distribution boards. FI items prompt further detailed investigation. Recommendations also include compliance timelines, potential hazards, and preventive measures.

Inspection Results and Documentation

All diagnostic data, test results, and measurements are compiled here. Supporting visuals are included to validate findings. Documentation should also note calibration details of instruments used, ensuring traceability and accuracy.

How to Write a Workplace Electrical Safety Report?

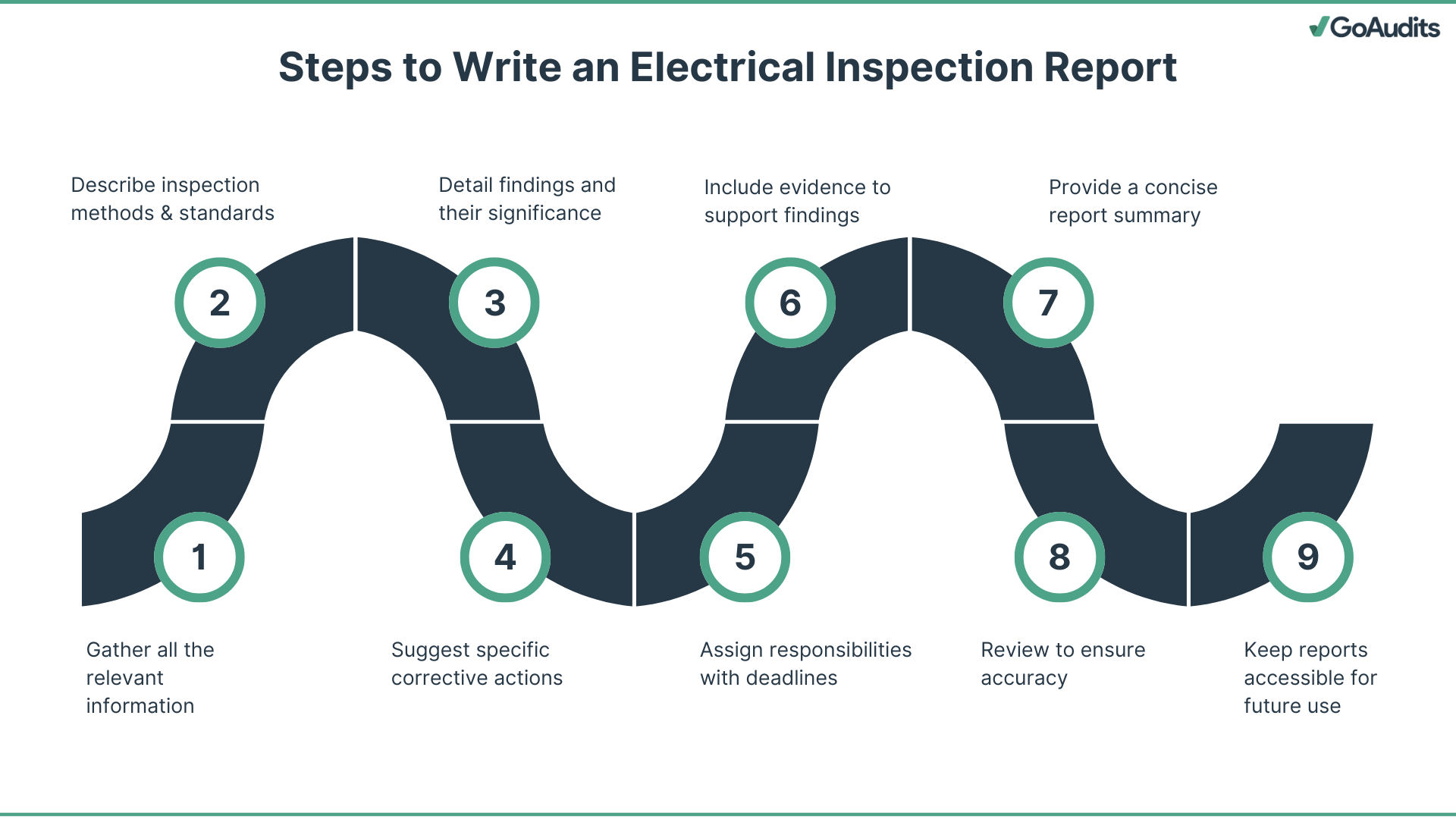

Once the electrical audit has been performed, it’s essential to document the findings clearly and systematically to ensure accountability and compliance with safety regulations and internal standards. The easiest and most efficient way to compile this information is by using an inspection software, which can automatically generate a well-structured, professionally formatted report. However, a standard workplace electrical inspection report can be prepared by following the steps below:

1. Gather Basic Information

Start by collecting all relevant details that define the context of the inspection:

- Site name and address

- Inspection areas

- Inspection date

- Who conducted the inspection

- Purpose of inspection

2. Define the Scope and Methodology

Describe the inspection method used: visual assessments, testing, verification of documentation, etc. Specify whether any instruments were used (e.g., voltage testers, thermal cameras). Note any reference standards (such as OSHA or NFPA 70E) followed.

3. Identify Key Issues and Hazards

Detail the specific findings and explain why they are significant. Common issues may include:

- Exposed wiring in the storage area

- Overloaded power strips

- Inadequate grounding in the server room

- Non-functional emergency stop buttons

Explain the consequences of each issue, such as personal injury, downtime, regulatory fines, or legal liability.

4. Recommend Practical Corrective Actions

For each issue, suggest actionable, realistic steps, such as:

- Secure loose wires and install appropriate conduit within 5 business days.

- Redistribute electrical loads and label outlets correctly.

- Engage a licensed electrician to inspect and rectify grounding.

- Replace non-functional components and test emergency protocols.

Ensure recommendations are specific, measurable, and feasible.

5. Assign Responsibilities and Deadlines

Create a task assignment matrix that clarifies ownership and ensures timely completion with specific deadlines. This structure promotes accountability and facilitates follow-up.

6. Attach Supporting Documents

Include all evidence to strengthen the electrical inspection report:

- Annotated photographs of deficiencies

- Completed inspection checklists

- Relevant pages from the electrical schematics

- Manufacturer guidelines or compliance references

- Previous audit reports or follow-up documentation

These records help validate findings and decisions made.

7. Summarize Key Takeaways

Provide a concise summary of the electrical audit report:

- Highlight critical safety risks discovered

- Reinforce the importance of timely corrective action

- Note any immediate actions already completed

Reaffirm your commitment to regulatory compliance and a safe working environment

8. Review, Share, and Approve

Before finalizing, review the electrical safety audit report for accuracy and completeness. Circulate it to stakeholders, including site managers, health and safety officers, and electrical contractors. Store a signed copy in both physical and digital formats.

9. Maintain Records and Conduct Follow-Up

Keep the electrical safety report accessible for future audits or inspections:

- Record completed actions and update status regularly

- Schedule follow-up inspections to verify issue resolution

- Log any recurring issues or trends for future prevention planning

Maintain transparency by documenting all updates and improvements over time.

Streamline Electrical Audits and Reporting with GoAudits

GoAudits safety inspection software transforms how you manage inspections, from data collection to follow-up. It combines mobile auditing, report automation, task management, and data analytics in a single, intuitive, and user-friendly platform. Here’s how you can use GoAudits to gain efficiency, improve compliance, and ensure nothing is left unresolved:

- Start with pre-built electrical audit checklists or modify them as needed to match your operational protocols. Simply upload your existing forms, we’ll digitize them for you, free of charge, and within 48 hours.

- Perform electrical audits with an intuitive mobile app that works even without the internet. Capture evidence with annotated photos, add e-signatures, apply timestamps, and geolocation data, ensuring full accountability.

- Generate professional electrical audit reports instantly after every inspection. Reports come pre-filled with captured photos, assigned actions, location data, and timestamps. Customize layouts and share reports via automated emails.

- Assign tasks during inspections, define priority levels, and set due dates. Task owners receive automated notifications and can update the status directly. Use workflows to manage task escalations and approvals within your organizational hierarchy.

- Set rules for distributing reports, assigning tasks, sending reminders, and escalating overdue actions. All activity is tracked in a centralized dashboard where you can monitor progress, review completion rates, and stay on top of your compliance goals.

- Gain actionable insights beyond audit scores and performance, identify risk levels across sections and inspections. Analyze historical data to detect recurring issues or trends.

Free & Customizable Electrical Inspection Checklists

GoAudits offers the following health and safety audit checklists. You can sign up for free and start using these checklists, or you can even digitize your electrical safety SOPs into actionable, digital checklists.

- OSHA Electrical Safety Inspection Checklist

- Electrical Safety Inspection Checklist

- Electrical Panel Maintenance Checklist

- Free Electrical Inspection Forms

- Electrical Safety Checks

- Electrical Risk Assessment Checklist

- Electrical Preventive Maintenance Checklist

- Commercial Electrical Inspection Checklist

- Electrical Monthly Maintenance Checklist

- Electrical Commissioning Checklist

- Electrical Certificate of Compliance Form